Your Essential Guide to Woodworking Gloves and Safety

This article discusses woodworkers, the tools they use, and the importance of staying safe with those tools.

This article discusses woodworkers, the tools they use, and the importance of staying safe with those tools.

Wood has been used for thousands of years to create items that are both useful and beautiful. Woodworking is defined as the activity or skill of making items from wood. It has helped humanity become more efficient, build substantial structures, and make life generally more comfortable.

The woodworking trade is responsible for cabinet making, furniture making, carving, joinery, carpentry, and woodturning. While the tools have changed somewhat over the years, the ever-enduring woodworking techniques have been passed down for centuries.

This article will tell you about woodworkers, the tools they use, and the importance of staying safe with those tools.

While one may be thinking that woodworkers and carpenters both build things out of wood and are therefore the same, you would be wrong. While carpenters usually use wood to build structures on a construction site and have to be familiar with various processes and tools, a woodworker deals primarily with machines and tools that prep and shape wood into various uses.

There is also a slight difference between the responsibilities of a woodworker versus those of a carpenter. For example, a woodworker's day may consist of setting up and maintaining automated machines or completing wood products by sanding, staining, and finishing them. A carpenter's responsibilities may include following blueprints or installing wooden structures, frameworks, and fixtures.

Check out this Carpentry construction page for those whose trade involves more carpentry work. Woodworkers may find the information useful, too, as both have similar PPE needs.

According to the Bureau of Labor Statistics (BLS), a woodworker manufactures various goods using wood, veneers, or laminates. While the name "woodworker" may bring to mind someone making wooden objects by hand, the job is much higher-tech these days. With the advancement of technology, this trade sets, operates, and tends to equipment like drill presses.

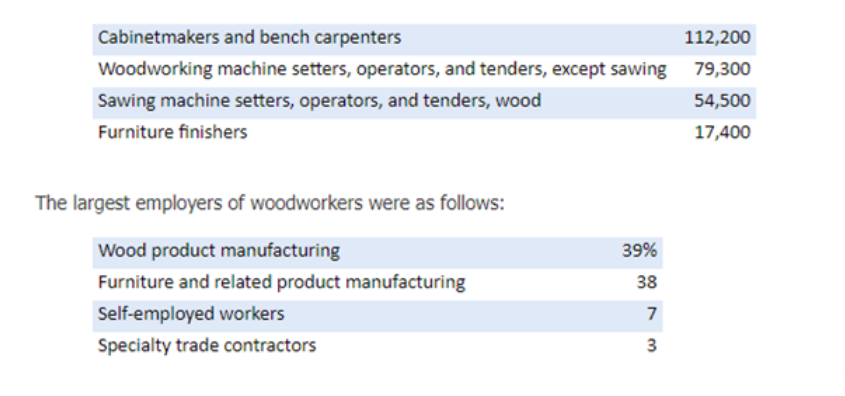

In 2019, there were 263,500 people employed as woodworkers in the U.S. Most of them were employed within cabinetmaking and wood product manufacturing. However, several different woodworking trades are rolled up under the title of "woodworking." Saw machine setters and furniture finishers are classified under this occupation. Here is a breakdown of some of the numbers and percentages in each employment sector:

While we seem to live in a world filled with plastic and other "disposable" materials, wood still has its place in the modern world, and woodworkers continue to play a significant role in our society. Some of their responsibilities may include:

Comprehending architectural drawings and blueprints;

Operating machines, such as saws and sanding machines;

Safeguarding products to meet industry standards and making the necessary corrections;

Choosing the appropriate cutting, milling, boring, and sanding tools for the job; and

Using hand tools to trim pieces or assemble products.

One place woodworkers can go to sharpen their skills is the Woodworkers Guild of America. This organization of woodworking experts has been educating the public with techniques and tips on creating wood projects since 2008. Becoming a member of the guild entitles you to exceptional education opportunities to keep your skills sharp and current.

Any woodworker will tell you that the first step to success is creating a functional workbench. Workbenches come in all shapes and sizes, but it's essential to find one that will perform the way you need it to and make your job easier.

Some characteristics you'll find familiar on most workbenches include:

Flat tops with a tool well on one end that can be covered if the wood you're working with is immense.

Square holes on the front edge drilled at regular intervals for bench dogs and holdfast clamps.

A cut slot where tools can be put with handles at the ready for easy reach while working.

Some benches may have storage cabinets, and others may be portable for jobs on the go. Make sure you have the right kind of workbench for your specific projects.

Even if you have the best bench for your needs, a project cannot succeed without the proper tools. Some of the necessary tools in a woodworker's toolbox include:

Drill

Hammer

Hand saws

Planes

Power saws

Sanders

Screw gun

In woodworking, tools need to be resilient and able to work with various woods for different functions. However, just about every device on the workbench can pose a physical threat to the woodworker without proper training or care. A medical study in 2014 showed that over 30,000 injuries occurred annually just from the use of table saws, only one tool in a woodworker's toolbox. This study showed that the most common table saw injuries were hand and finger lacerations resulting in a tendon, nerve, or vascular damage or amputation.

When any tool is being utilized, the woodworker needs to be on guard. The BLS reports that most cut injuries found across all U.S. industries result from working with tools. And, the number holds true for woodworkers, too. The number one injury woodworkers sustained in 2019 was cuts or lacerations, with the BLS reporting 790 injuries. That is higher than sprains and strains, which might surprise some woodworkers due to the amount of awkward lifting that can occur on the job.

Continue reading this article in its entirety here to learn about common hazards and injuries that face woodworkers.

This article was previously featured on MCR Safety's blog.

MCR Safety has over forty years of experience as a leader in the field of personal protective equipment (PPE).Our assortment of offerings includes gloves, glasses, and garments which are made from the highest quality materials available to ensure maximum safety, comfort, and style. Products formally promoted under our legacy brands, such as, Memphis Gloves, Crews Glasses, and River City Garments; are being transitioned to our full line branding of MCR Safety.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)