Centers are essential for accurately positioning a workpiece on a lathe between the chuck or headstock spindle and the tailstock spindle. They enable the workpiece to rotate or revolve while maintaining concentricity and stability during turning operations.

Lathe Center Buying Guide

Understand the full range of lathe centers and learn how to select the right setup for accurate workholding and consistent results.

Types of Centers

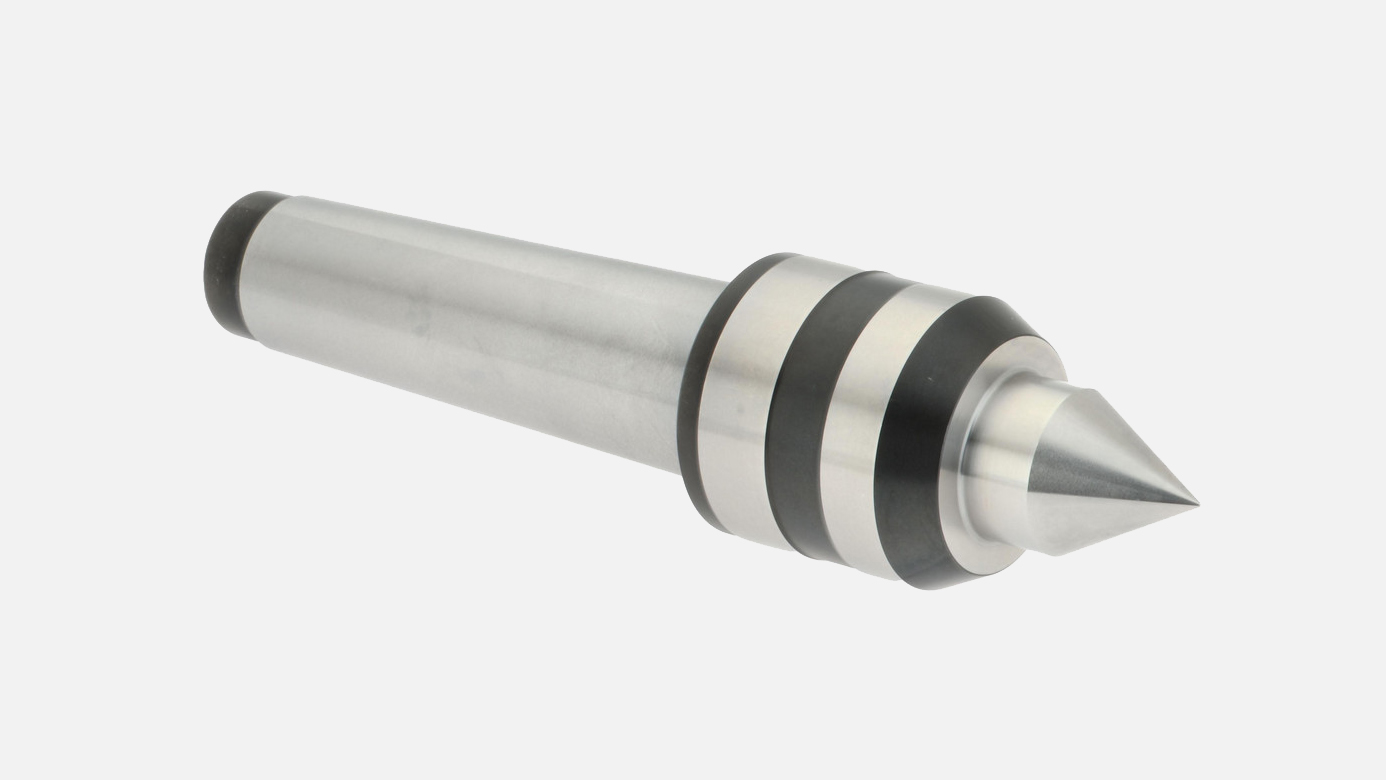

Live Centers (Revolving Centers)

A live center lathe setup uses a center that revolves with the workpiece. Ball bearings inside the live center reduce wear on the center tip and allow for higher turning speeds without the need for separate lubrication. Live centers can handle more force and maintain a tighter grip, reducing side movement during turning.

Standard and Extended Points

- Standard Point Live Centers: Provide maximum rigidity over extended points, although tool clearance may not be as strong.

- Extended Point Live Centers: Recommended when exceptional tool clearance is required.

Bull Nose and Spring-Loaded Live Centers

- Bull Nose Live Centers: Feature a shallower end for securely holding tubing, pipe, or hollow shafts.

- Spring-Loaded Live Centers: Expand lengthwise to compensate for thermal distortion during cutting.

Live Center Applications

Different live center lathe models are designed for specific operations:

- CNC Heavy Duty: Ideal for CNC lathes requiring high precision.

- Super Accurate: Designed for grinding applications.

- Spring Type: For light- to medium-duty work.

- Heavy Duty / Extra Heavy Duty: For turning large parts.

Bearing configurations:

- Triple Bearing: Medium-duty work.

- Double Bearing: Light-duty work.

- Quad Bearing: Handles heavy loads.

- Bull Nose: Parts with large center holes.

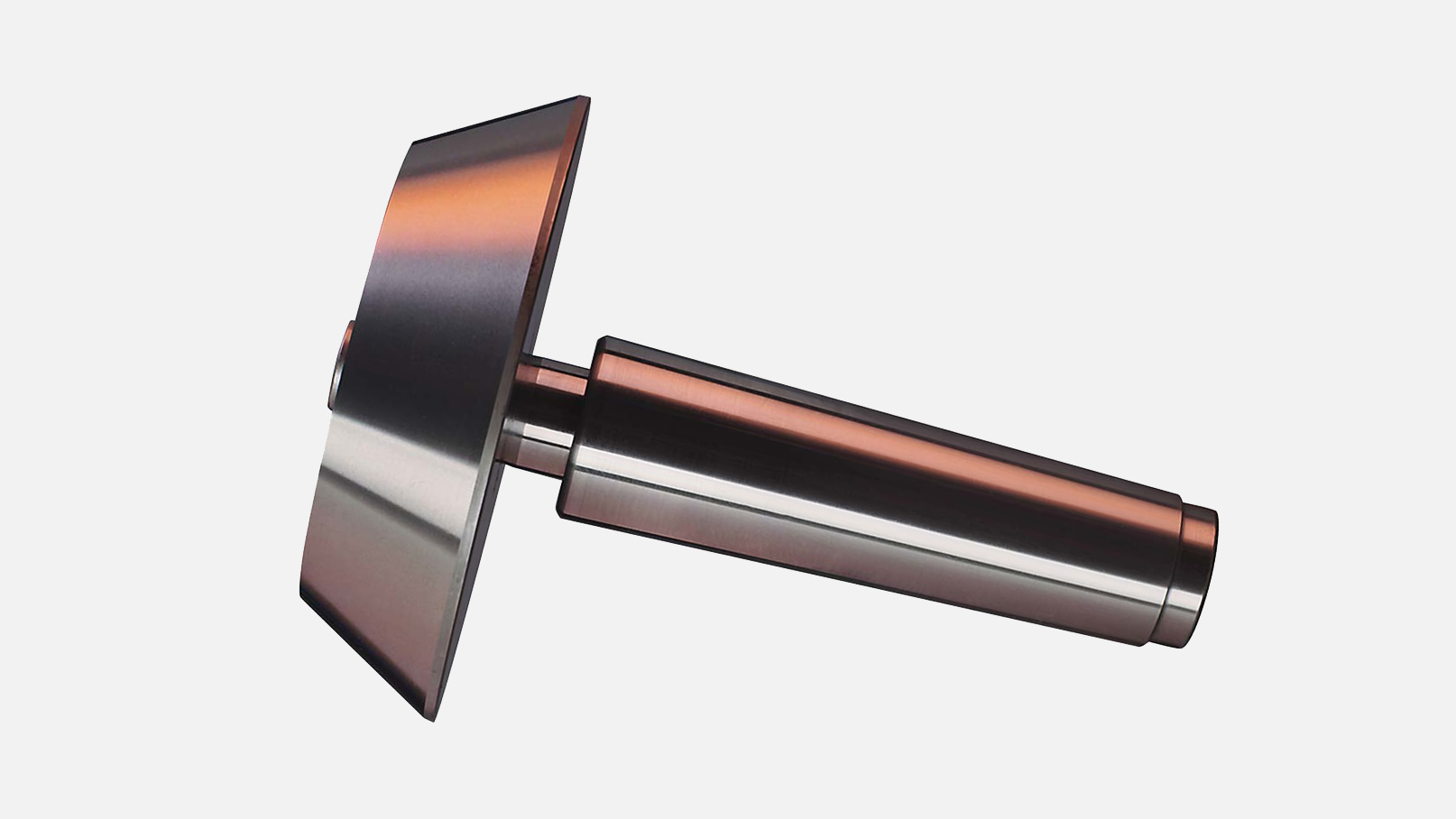

Dead (Plain) Centers

Dead centers, also called plain centers, do not rotate. They support the workpiece at either the fixed or rotating end of the machine. Because the workpiece rotates against the stationary center, lubrication is required to prevent friction welding.

Full and Half Dead Centers

- Full Dead Centers: Provide high precision for grinding and some turning operations.

- Half Dead Centers: Allow a cutting tool to face the end of the work without interference. Best for grinding small parts where extra wheel clearance is needed. Available in full carbon steel or with carbide tips.

Center Tapers

A center taper provides the connection between a tool, arbor, or center and its mating part, ensuring accurate alignment and easy separation. The three primary taper families are:

Morse Tapers

- The most common self-holding standard taper; used on small cutting tools such as end mills, drills, reamers, and sometimes machine spindles.

- Available in eight standard sizes (0 to #7) with a taper of roughly 5/8" per foot.

Jarno Tapers

- Standard taper with 0.600" per foot, used on some machine tools.

- Size designations correspond to dimensions: big end diameter = size ÷ 8, small end = size ÷ 10, length = size ÷ 2.

- Example: Jarno #7 measures 0.875" across the big end, 0.700" across the small end, and is 3.5" long.

Brown & Sharpe (B&S) Tapers

- An alternative to Morse tapers, available in sizes 1 through 18 (sizes 7, 9, and 11 are most common).

- Actual taper is approximately 0.500" per foot.

Tips for Choosing a Live Center Lathe Setup

- Application: Choose a live center lathe for high-speed turning, heavy loads, and applications requiring minimal side movement.

- Material & Size: Select the right point type and bearing configuration based on the workpiece size and machining requirements.

- Dead Centers: Use for high-precision grinding or when rotation of the center is not desired; just remember to lubricate.

- Taper Compatibility: Verify that your Morse, Jarno, or B&S taper matches your machine for accurate alignment.