Quick change discs are used for leveling, finishing, grinding, deburring, and blending. Their twist-on, twist-off attachment system eliminates the need for installation tools, enabling fast disc changes and improving productivity by reducing downtime.

Quick Change Discs: Maximize Efficiency with Every Turn

Understand disc types, materials, and attachment systems to improve productivity across grinding, blending, and finishing tasks.

Quick Change Discs

Quick change discs are suitable for stock removal on a wide range of materials, including ferrous and nonferrous metals, composites, and fiberglass. They are typically used with right-angle grinders, which are most commonly air-powered but can also be electric.

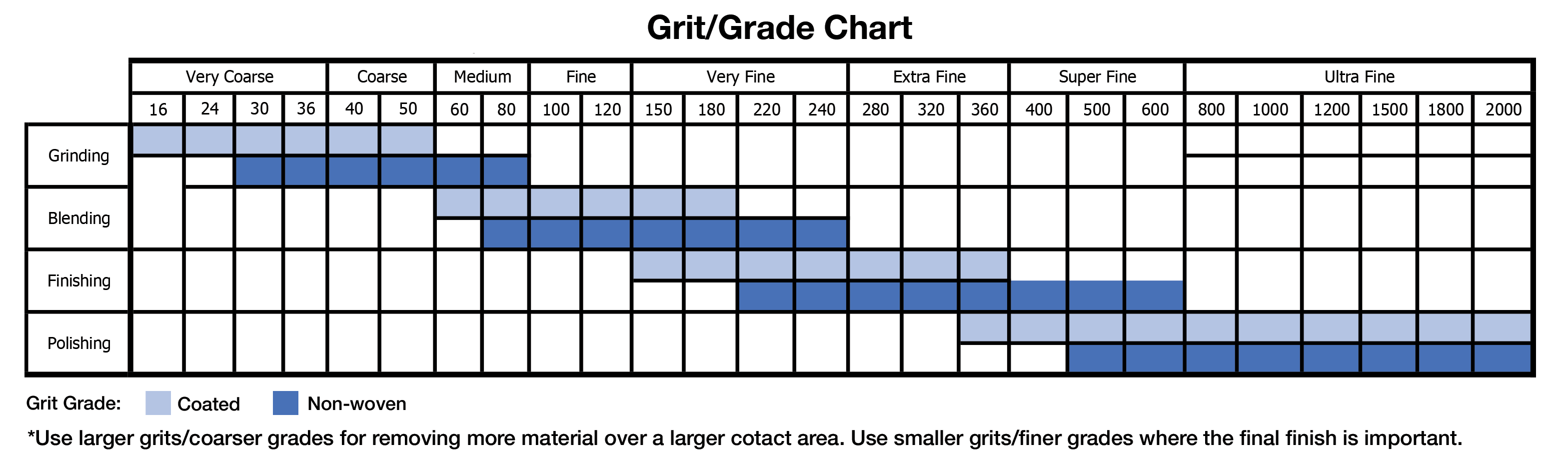

Coated & Non-Woven Quick Change Discs

Coated abrasives are suitable for most applications, from grinding to polishing. They feature a thin layer of abrasive material bonded to a backing of fiber, paper, cloth, or rubber.

Non-woven abrasives reduce undercutting and surface gouging. They are commonly used for deburring, surface preparation, and final finishing.

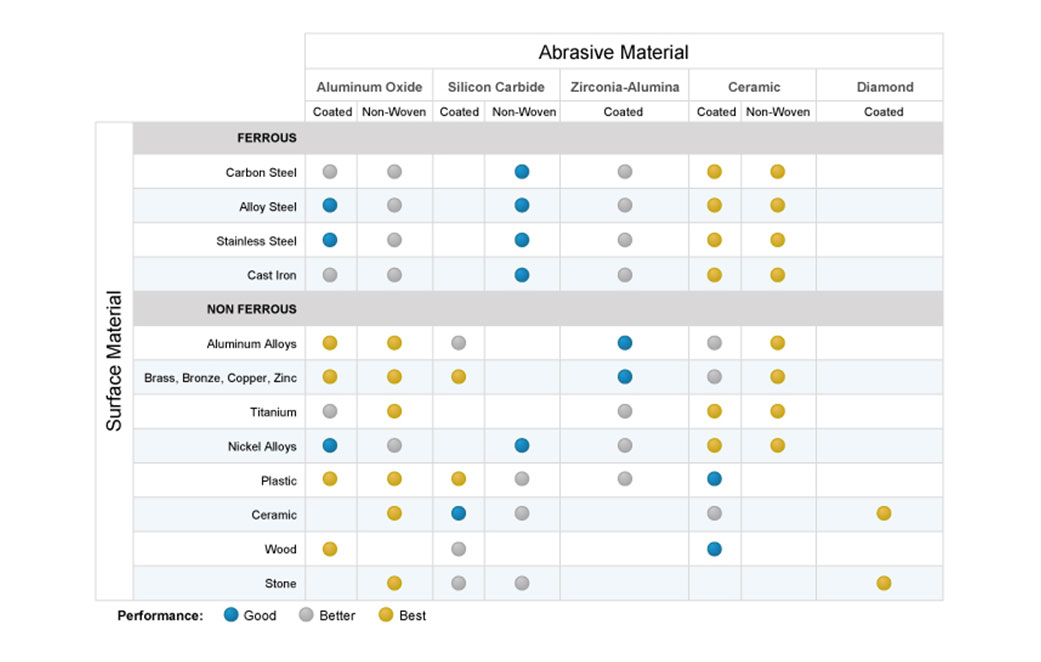

Material Chart

Choosing the correct abrasive material for your surface can shorten grinding time, reduce cost, and prevent premature wear. Aluminum oxide, for example, is a great all-around abrasive material, while diamond is used on specific materials like ceramic.

Material Definitions

Aluminum Oxide is the most commonly used abrasive for quick change discs. It is tough, economical, and fracture-resistant, ideal for general-purpose deburring and blending on ferrous alloys, high-tensile materials, and wood.

Ceramic abrasives provide a sharp, high-purity grain that runs cooler during use. Ceramic quick change discs are commonly used for precision grinding of steels, hard alloys, and exotic materials, and last longer than natural aluminum-based abrasives.

Ceramic Alumina quick change discs are well-suited for general-purpose deburring and blending. They are often used on ferrous alloys and high-tensile materials.

Diamond abrasives are among the hardest abrasive materials. Diamond quick change discs are typically used for grinding and polishing hard surfaces like ceramic, stone, and aluminum alloys.

Silicon Carbide quick change discs cut fast and are harder than ceramic. They’re best for nonferrous metals and low-pressure applications.

Zirconia Alumina is best for medium- to heavy-material removal. The very fine material grain microstructure constantly fractures to produce new sharp edges. It is used on carbon steels, aerospace alloys, forgings, some stainless steels, and more.

Attaching Systems

Type P quick-change discs

Type P quick-change discs feature a snap-on/snap-off system. They are interchangeable with TP and Type I Styles.

Type R quick change discs

Type R quick change discs use roll-on/roll-off style fasteners (external thread). They are interchangeable with Roloc, TR, and Type III styles.

Type S quick-change discs

Type S quick-change discs use a turn-on/turn-off style fastener (¼–½ turn to lock in place). They are interchangeable with TS and Type II styles.

Coated & Non-Woven Abrasives Discs from MSC Industrial Supply

Adhesive-Backed/PSA Discs

Ideal for contoured surfaces, these discs are used for blending, finishing, and polishing. They are heat resistant and feature flexible adhesive backing for easy attachment or removal from the backing pad.

Fiber Discs

Used for stock removal, grinding, blending, and weld dressing. Made with durable fiber backing that resists tearing and loading. Mounting requires a backing pad with a retainer nut, adhesive, or clamp.

Flap Discs

Designed for stock removal, grinding, blending, deburring, finishing, and polishing. These discs consist of layered flaps on a rigid backing and mount directly to the sander or grinder via a through hole or threaded hub.

Hook and Loop Discs

Used for blending, deburring, and finishing. They attach via a hook-and-loop fastening system, allowing for a secure hold and easy disc removal.

Slotted Overlap Discs

These discs are used for blending, deburring, and finishing. The layered slots contract to fit snugly inside the workpiece. They mount on a threaded mandrel compatible with most drill chucks.

Safety Tips

Improper use of abrasives can lead to serious injury or death.

Always follow ANSI safety standards when using abrasive products.

Wear personal protective equipment (PPE), such as safety glasses, face shields, gloves, aprons, hearing protection, and dust protection.

Use wheel guards as provided by the tool manufacturer.

Never exceed the maximum speed rating of the backup pad and disc.