Dowel pins are cylindrical tools designed to secure into machinery by fastening different workpieces together. They are effective when aligning devices during reassembly. Dowel pins are most often associated and used in conjunction with socket screws. They absorb shear loads, allowing the socket screw to take up the tensile loads in an application.

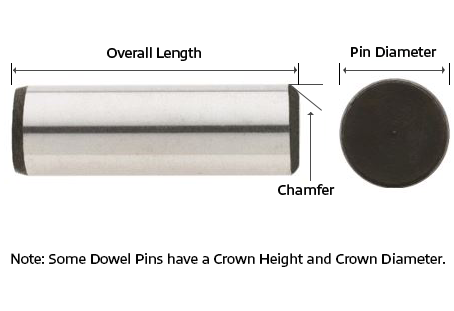

Dowel Pins Technical Guide & Diagrams

In fastening and assembly, these cylindrical tools help provide stability. Discover the ideal dowel pin styles, types, and materials for your workpieces.

Standards

To comply with ASME B 18.8.2, hardened ground machine dowel pins have a core hardness of RC 47-58 and a minimum case hardness of RC 60. Surface finish is 8 microns maximum. Made 0.0002 inch over a standard diameter, these dowel pins fit into a reamed hole. Special oversized styles are 0.0010 inch oversized, so the damaged hole may be further opened up to accommodate the new pin.

Dowel Pin Types

Precision

Precision dowel pins are effective in interference fit applications. Choose from various fasteners based on hole size, tolerance, and ductility.

Grooved

Grooved dowel pins feature grooves along the side for various applications. If the markings run along only a portion of the pin, the smooth end allows the connected unit to rotate freely. These grooved pins allow materials to pass through during insertion. They are ideal for blind holes.

Oversized

Oversized, also known as press-fit or repair dowel pins, are 0.001 inch larger than standard dowel pins. This allows damaged holes to be opened wider to accommodate the new pin. They are ideal for fastening into out-of-round holes or softer materials.

Pull-Out

Pull-Out dowel pins feature an internally threaded hole to allow for removal and reuse with a standard screw or pull-out tool. They are ideal for blind holes. A corresponding wrench fits into the dowel pin hole for easy removal. Pull-out dowels are not referenced by any standard of ASTM or ASME, but by custom, have the same hardness as hardened ground machine versions.

Standard

Standard dowel pins fasten parts and maintain consistent alignment. A chamfered end provides easy dowel pin insertion.

Dowel Styles

Standard round (not vented): Has a smooth finish. Used in through-hole applications. Some offer a flat surface without an internal thread.

Vented: Designed to relieve trapped air. All vented styles are for use in blind-hole applications.

Spiral vent: Features a groove cut from end to end. Internally threaded.

Flat vent: Features a ground flat chamfer along one side. Internally threaded.

Materials

Alloy steel is the strongest of all steel types. It has high tensile strength and offers excellent durability for steel dowel pins that resist wear, fatigue, and galling.

Case-hardened carbon steel is less brittle than carbon steel and will not fracture under high stress.

Stainless steel is a strong, corrosion-resistant alloy with excellent heat resistance. These metal dowel pins are for use in high-stress, outdoor, and corrosive applications.

Nylon is a lightweight, nonconductive material that is resistant to impact, wear, and abrasion. It is ideal for electrical applications or where corrosion is a concern.

Wooden dowel pins are ideal for structural reinforcement in cabinetry and furniture building. Offered in both fluted and spiral styles, they are effective for simple repairs and fast joinery.

Operational Tip

Due to the high hardness design of the pin’s surface, a dowel should be pressed into a reamed hole with a hammer made of softer material, rather than hammered or driven. This prevents the pin from shattering and causing injury. Caution: Safety goggles must always be worn when installing dowel pins.

More Holding and Alignment Pins from MSC

Taper pins

Taper pins have one end slightly larger in diameter than the other, which results in a uniform taper for simple, effective fastening. They create a stop or wedge in machinery applications that require frequent assembly/disassembly.

Spring pins

Spring pins, also known as roll pins, are hollow, self-retaining fasteners that secure multiple components and parts together. They are meant for light-duty applications instead of solid dowel pins.

Pilot pins

Pilot pins are self-clinching tools that easily embed in sheet metal and other soft materials. Insert these fasteners into mounting holes for alignment applications.