Drill bits are essential for a wide range of operations, from routine maintenance to high-volume precision hole making. To select the right drill, consider the following: choose the appropriate drill style, grade, and length for the task; match the tool material to the workpiece; and select the optimal drill point for your application. For enhanced performance and extended tool life, consider applying a coating or surface treatment.

Basics of Drill Bits

Drill Style, Grade, and Length

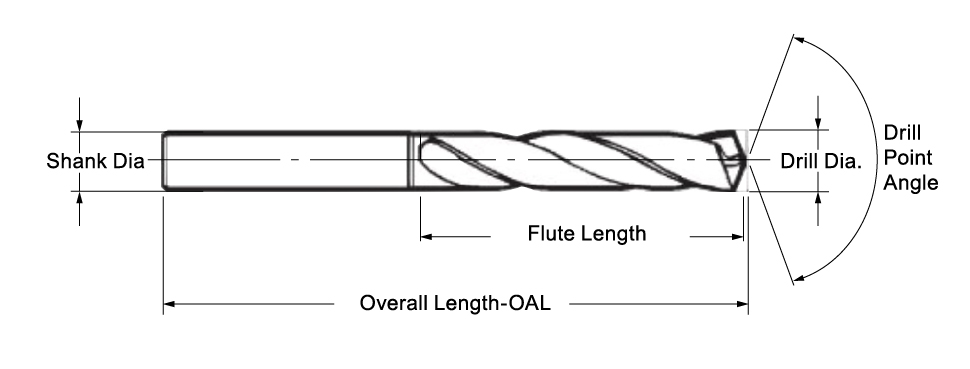

With all the choices on the market, selecting the right drill bit can be hard. If you know the diameter and depth of the hole, the number of holes you need to make, and the type of job, you are already halfway there.

Styles

Drill Points

Drill point geometry significantly affects performance. Flatter points offer smoother cutting action, while steeper point angles increase torque for faster penetration.

Styles

The 118° point is a versatile, all-purpose design commonly found on general-purpose tools. It’s ideal for drilling soft metals, wood, and plastics.

The 135° split point is designed for cutting metal. Its self-centering tip prevents walking or slipping, making it a standard feature on heavy-duty drills.

The 130° point is commonly found on high-performance HSS parabolic drills. It disperses heat effectively and helps maintain straightness in deep-hole drilling.

140° point is common on high-performance carbide drills, and helps get the cutting edge into tough materials quickly.