• Identify chemicals handled and conduct analysis of potential exposures.

• Evaluate physical risks such as sharp objects, abrasions, cuts, and slashes.

Electrical safety gloves can be used for a variety of applications, including electrical work, cutting, and protecting yourself against cuts, abrasions, and hazardous materials.

• Seams run along the back of the glove at every finger.

• Features a straight thumb design.

• Commonly used for light- to medium-duty applications.

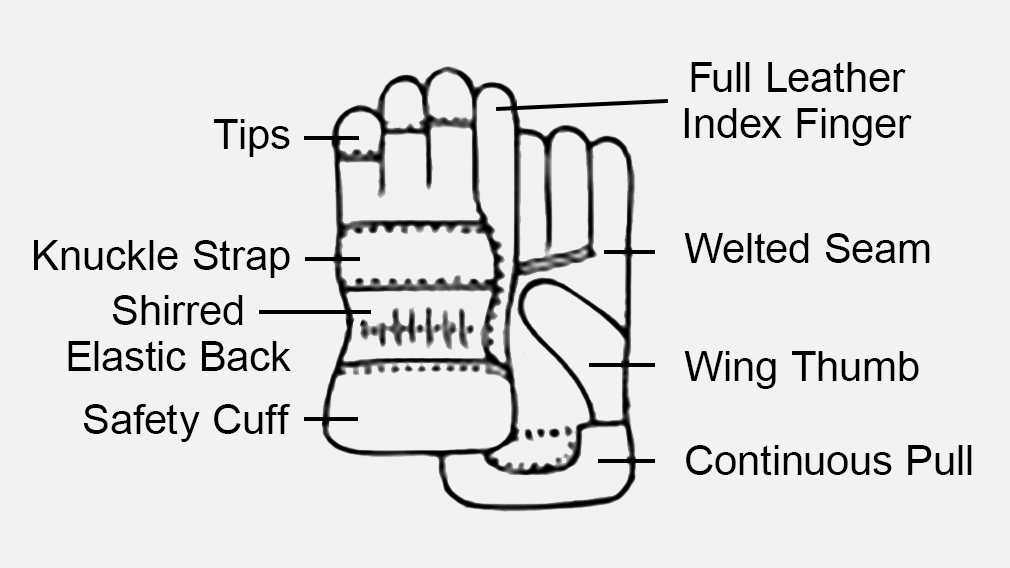

• Fully wrapped leather index fingers and thumbs for durability.

• Reinforced with leather fingertips and leather knuckle straps.

• Wing thumb design for comfort and flexibility.

• Shirred elastic back ensures a snug fit.

• Continuous pull with open cuff for easy on/off.

• Typically, generously sized for comfort.

• It can be worn on either hand, doubling the usable wear surface.

• Available in many materials, including:

◦ Disposable gloves (vinyl, latex, nitrile, polyethylene).

◦ Machine knit, cotton lisle inspectors, natural jersey.

◦ Kevlar knit and reinforced cut-resistant gloves.

• Versatile design for both single-use and reusable applications.

• Made from elasticized knit fabric, similar to a sweatshirt cuff.

• Fits snugly around the wrist to keep out dirt and debris.

• 1 ½"–2" cuff that protects the wrist.

• Designed for easy on/off while offering light coverage.

• 2 ½" cuff for added wrist protection.

• Allows for quick removal when needed.

• 4 ½"–5" cuff that extends over the wrist and forearm.

• Provides maximum coverage and protection.

• Open-ended design for easy on/off.

• Commonly used in drivers’ gloves for convenience.

Strong and supple leather, split into: ◦ Top grain (smooth finish). ◦ Split grain (suede finish).

Once tanned, it is used in drivers, leather-palmed, welding, and heat-resistant gloves.

Known for ruggedness and flexibility.

Characterized by large pores from the removal of coarse hairs.

Performs well in wet conditions — stays supple even after drying.

Preferred when dexterity is most important.

Naturally high in lanolin, which keeps the leather soft, flexible, and durable.

Offers the best feel and comfort of any leather glove.

Gloves designed for chemical protection are available in different materials and constructions. The best option depends on the specific chemicals and work environment.

Available unlined or flock-lined.

Flock lining makes gloves easier to put on and remove.

Lightweight and flexible, suited for applications that require dexterity.

Features inner linings, typically knit or jersey.

Both absorb perspiration and provide insulation.

Knit linings: lightweight, comfortable.

Jersey linings: thicker, offering better protection in hot or cold conditions.