Always choose the proper tool for the job. Among the most common hand tools are various types of hammers, mallets, and other striking tools. These come in many styles and sizes (hammers are typically sized by weight), depending on their specific purpose and design. Understanding the different types of hammers is crucial to help you select the right tool. Some important things to consider include:

Master Every Strike with the Right Types of Hammers

Understand the differences in head shapes, handle materials, and performance so you can choose with confidence.

Selection Criteria

Head Components

Contractor & Machinist Hammers

Claw Hammer

- Used for general woodworking and home repair tasks.

- Curved claw design offers better leverage for pulling nails with minimal effort.

- Straight or rip claw styles are primarily used in heavy-duty or professional carpentry, ideal for ripping boards and framing work.

Nail Hammer

- 20 oz. or less

- Less than 13 ½" in length

- Curved, straight, or rip claw

- Fiberglass / Wood / or Graphite Handle or one-piece Forged Steel

Framing Hammer

- More than 16" in length

- 10 oz. or more

- Plain or checkered face

- Rip Claw

- One-piece forged steel or wood handle

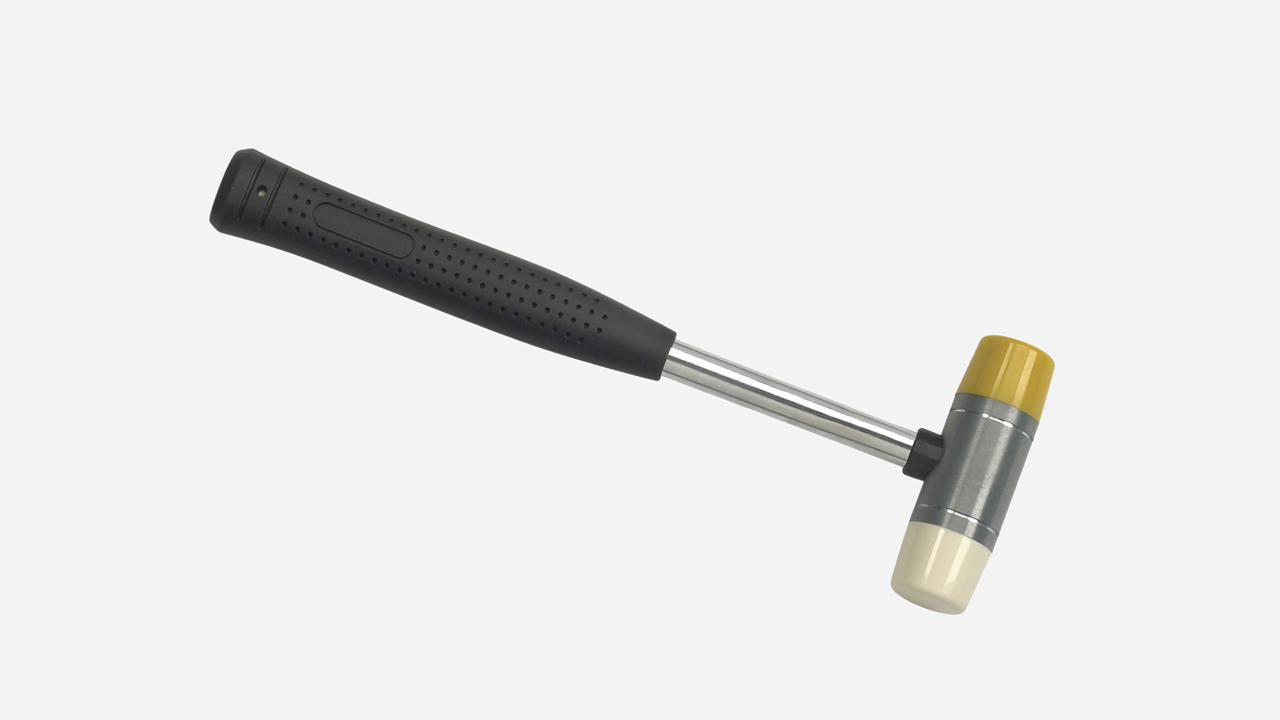

Replaceable Face Hammer

- Faces are made of a variety of materials, including tough plastic, nylon, urethane, copper, and rawhide.

- These different materials are used in applications that require a non-marring effect on various surfaces.

- Many high-quality soft-faced hammers feature replaceable plastic faces for extended tool life.

- Applications that require non-marring blows, such as automotive, jewelry work, or furniture assembly, soft-faced hammers should be used.

Ball & Cross Pein Hammer

- Ball pein hammers are commonly used in metalworking for riveting, center punching, and shaping soft metals.

- Often paired with cold chisels for cutting and chipping tasks.

- Available with wood, fiberglass, or steel handles for durability and user preference.

- Some versions include steel shot inside the head to reduce bounce back during strikes.

- Heavy-duty cross pein hammers are for use with unhardened metals and are designed for shaping and bending metals.

- Suitable for fabrication, blacksmithing, and other heavy-duty metal-forming applications.

Demolition Hammers

Blacksmith Hammer

- Designed specifically for metal work but works well for most hard-hitting applications.

- The key difference between blacksmith hammers and other demolition hammers is the unique shape of the head.

Drilling Hammer

- Intended for hard-hitting in confined spaces.

- Compact and extremely durable.

- Drilling hammers are forged with hardened & tempered steel heads.

- Commonly weighs between 2 to 3 pounds.

Engineer Hammer

- Designed for hard-hitting applications such as demolition, masonry work, and driving stakes.

- Slightly heavier than drilling hammers, typically weighing 2.5 to 4 lbs for added striking force.

- Features a longer handle for extended striking tasks in open work areas.

Sledge Hammer

- Large, heavy hammer designed for tasks that require maximum striking force, such as driving stakes, installing fence posts, and breaking up concrete.

- Features an octagonal head with a flat striking face for powerful, controlled blows.