Anti Fatigue Mats: Types, Uses, and Rubber Compounds

Types of Anti Fatigue Mats

These popular mats are ideal for dry areas, featuring an abrasion-resistant surface bonded to a cushioned sponge base for lasting comfort and durability.

The surface of an anti fatigue mat can have a design molded in, like diamond-plate, corrugations, circles, or be smooth. Surfaces with designs tend to be more slip-resistant. Polished mats are easier to clean, especially in the presence of fine dirt or dust particles.

The sponge base is generally between 3/8 and 3/4 inches thick. In general, the thicker the base, the softer the mat. The type of sponge is also crucial. 100% PVC sponge is usually found in economy products. 100% PVC sponge is stiffer and bounces back more slowly than blended sponge-based material. A blend of PVC with Nitrile rubber sponge is over 50% softer than PVC alone and a better choice when users stand on the mat for extended periods. Anti fatigue mats with blended sponge bases can last 3-5 years of round-the-clock use. Mats with 100% PVC sponge will last about half as long.

PVC Sponge Without Wear Surface

A cost-effective and popular option, these basic anti fatigue mats are ideal for dry areas. Easy to cut and commonly sold in rolls, they offer 6 to 12 months of use. Over time, the sponge compresses and loses resiliency, especially in high-traffic areas—though the mat remains intact.

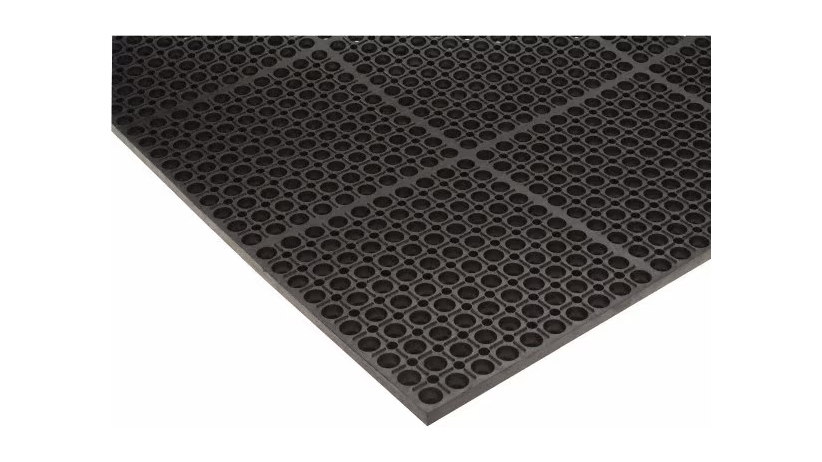

Molded Rubber Mats

A popular choice, molded rubber mats come in various compounds and configurations. They’re ideal for wet environments, oily or greasy areas (from animal or mineral oils), and locations near machinery that require cutting fluids. For optimal performance, the rubber compound must match the specific conditions of use.

Molded Rubber Compounds

Natural Rubber

Ideal for dry and wet areas, natural rubber mats are resistant to most detergents and maintain performance in environments with water exposure.

50% Nitrile Rubber Blend

Suitable for all applications containing natural rubber, with added resistance to saltwater, animal fats, mineral and vegetable oils, brake fluid, hydraulic oils, and mineral-based cutting fluids.

Cutting Fluid Resistant (CFR) Rubber Blend

Offers all the benefits of nitrile blends, with enhanced resistance to semi-synthetic cutting oils and high concentrations of mineral, hydraulic, and vegetable oils.

Molded Rubber Configurations

Typically 1/2" to 7/8" thick, molded rubber mats come in a wide range of sizes. Thinner, smaller mats are lighter and easier to clean, while thicker mats provide greater elevation—ideal for wash-down areas. Many feature perforations for drainage in wet environments, while solid versions make dry debris cleanup as simple as sweeping.

Molded Rubber with Holes and Grit: Provides superior slip resistance in wet and slippery environments—ideal for maximum traction and drainage.

Molded Rubber with Holes: Designed for wet areas where drainage is needed but maximum slip resistance isn't critical—an effective, economical solution for moderate traction requirements.

Molded Rubber with Solid Surface and Grit: Ideal for areas contaminated with slick dry substances like powder, graphite, PTFE, or other slippery compounds, providing enhanced traction and safety.

Molded Rubber with Solid Surface: Easy to clean by sweeping, especially effective in areas with debris such as metal shavings or wood chips.

Molded rubber mats typically last 1 to 3 years, depending on environmental conditions and cleaning frequency.

Modular Tiles:

These interlocking tiles snap together easily to cover large floor areas and come in various sizes and thicknesses. Thinner tiles suit lighter-duty spaces like locker rooms or showers, while thicker, larger tiles create raised flooring capable of withstanding heavy cart traffic and extreme use. Options include drainage holes, grit surfaces, and ramped edging to reduce trip hazards and ease cart access.

Molded Urethane:

A premium compound emerging in anti fatigue matting, urethane offers exceptional comfort, durability, and chemical resistance. A 5/8" thick urethane mat delivers more cushioning than 1" mats made from other materials. Ideal for dry areas and environments with chemical exposure, urethane mats have a life expectancy of over 5 years—making them a top-tier choice.

Runner Mats:

Made of vinyl or rubber without sponge backing, runner mats protect floors and enhance traction in high-traffic areas. Solid runners are best for dry environments, while slotted versions offer improved slip resistance in wet areas. Thicker materials provide greater durability under heavy use.

Types of Entrance Mats

Carpet Mats

Designed for indoor use, carpet mats help remove dirt and moisture from footwear. Surface design—including fiber type and density—greatly impacts performance and effectiveness.

Polypropylene

These fibers effectively trap and retain more moisture than most other fiber types.

Nylon

Dries faster than polypropylene, making it ideal for maintaining a clean, dry surface.

The higher the fiber content, the more water the mat will hold. Carpet mats have three types of surface designs:

Tightly Woven, Closed-Loop Construction: Resists visible wear, shows fewer traffic patterns, and offers enhanced durability over time.

High-Low (Ribbed) Surface: Effectively scrapes debris from shoes while capturing large amounts of dirt between cleanings.

Plush Pile: Absorbs the most moisture but is more prone to showing footprints and tracking.

Molded Rubber Entrance Mats

Designed for outdoor use, these mats act as effective scrapers, removing dirt, snow, and water before it enters the building. For optimal cleanliness and moisture control, pair a molded rubber mat outside the entrance with a carpet mat just inside the doors.