Choosing the right motor is critical to ensure your equipment performs at its best. This guide breaks down the most common types of motors, including general-purpose, HVAC motors, and special duty options, to help you make the best selection based on application, power, environment, and design.

Power Up with the Right Motor

Compare motor types by power, phase, speed, and fit to match your machine’s requirements.

Types of Motors & Their Applications

Category | Common Applications | Common Types of Motors |

|---|---|---|

General Purpose | 1. Belt Drive Fans 2. Belt Drive Blowers 3. Pumps 4. Conveyors 5. Machine Tools 6. Compressors 7. Material Handling | 1. Split Phase 2. Capacitor Start 3. Three Phase |

Definite / Special Purpose | 1. Washdown 2. Hazardous Location 3. Farm Duty 4. Close-Coupled Pump 5. Fire Pump 6. Pool & Spa Pump 7. Elevator Duty 8. Gate & Door 9. Commercial Jet Pump | 1. Permanent Split Capacitor (PSC) 2. Split Phase 3. Capacitor Start 4. Three Phase |

HVAC | 1. Condenser Fan 2. Direct Drive Blower & Fan 3. Belt Drive Blower & Fan 4. Unit Heater 5. RoomAC/FanCoil 6. Evaporative Cooler 7. Hot Water Circulator 8. Oil Burner 9. Unit Bearing 10. Cooling Tower 11. Refrigeration· 12. Air-Circulating | 1. PSC 2. Shaded Pole 3. Split Phase 4. Capacitor Start 5. Three Phase |

Tip: Some motors work across multiple applications.

How to Select the Right Motor

Horsepower (HP)

Indicates the power output of the motor, usually specified as a fraction or in a whole number. Small motors can be rated in watts. Choose a motor with equal or greater HP than the one being replaced.

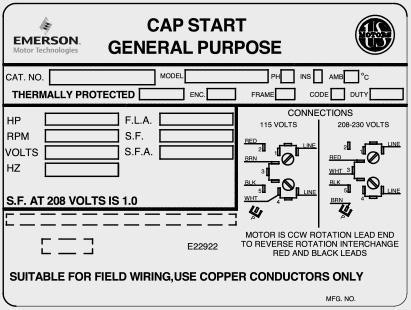

Tip: If no HP or Watt rating is available, amp draw (typically available on the nameplate) provides the next best characteristic to sizing the motor.

Voltage

Voltage is the power rating at which the motor operates. A motor should operate at ±10% of the nameplate voltage. A 230-volt motor should operate within a range of 207 to 253 volts. A slash (/) between listed voltages indicates a different internal connection for each voltage. A hyphen (-) between voltages typically means the same internal connection is used for both.

Tips:

Match to the supplied voltage.

If the supplied voltage is 115, and the replacement motor is 115/230, the motor will work if connected for 115 volts.

Frequency/Hertz (Hz)

The term hertz or frequency was formally called “cycles” and is nearly always 60 hertz in the USA and Canadian applications. Some foreign countries, especially Europe, use 50 hertz power supplies. Match Hz exactly or with a 50/60 Hz-capable motor.

Revolutions Per Minute (RPM)

RPM indicates how fast the motor shaft will rotate under the specified load (HP). Multi-speed motors can be rated either with the RPM and the number of speeds (1075/3-speed) or with the RPM for each speed.

Poles and RPM are used interchangeably. Reference the chart below.

Poles | Synchronous RPM | Typical Nameplate RPM |

|---|---|---|

2 | 3600 | 3000-3450 |

4 | 1800 | 1625-1750 |

6 | 1200 | 1050-1140 |

8 | 900 | 825-850 |

Tips:

Match RPM within 5% of nameplate RPM.

Remember that the horsepower (HP) rating of the motor only applies to the high speed of a multi-speed motor. As the speed is reduced, the horsepower is reduced.

Motor Types by Electric Phase

Select the type of motor based on typical characteristics and uses.

Motor Type | Hp Range | Typical Nameplate RPM | Typical Characteristics | Typical Uses |

|---|---|---|---|---|

Shaded Pole, Single Phase | Up to 1/2 HP | Multi-Speed, 1050, 1550, 3000 | 1. Low efficiency 2. Not for belt drive as a rule 3. Air over design is usually required 4. Always single voltage 5. Non-reversible 6. Low starting torque | 1. Small Fans and Blowers 2. Unit Heaters 3. Space Heaters 4. Humidifiers 5. Freezer Blowers 6. Window Fans 7. Floor Fans 8. Portable Evaporative Coolers |

Permanent Split Capacitor (PSC), Single Phase | Up to 1 HP | Multi-Speed, 825, 1075, 1625, 3250 | 1. Improved efficiency vs. shaded pole 2. Not for belt drive, as a rule 3. Air over design is usually required 4. Typically single voltage 5. Low starting torque | 1. Small Mounted Fans 2. Air Circulators 3. Blowers 4. Room AC and Central AC 5. Condenser Fans 6. Evaporator Fans 7. Furnace Blowers 8. Unit Heaters 9. Window Fans 10. Oil Burners 11. Pool Pump 12. Door Operators 13. Animal Confinement Fans for: Poultry, Hogs, Cattle |

Split Phase, Single Phase | Up to 1 HP | 850, 1140, 1725, 3450 | 1. Moderate efficiency 2. Typically used in belt drive applications 3. No capacitor needed for start-up 4. Available in single voltage and dual voltage 5. Generally reversible rotation 6. Medium starting torque | 1. Belted Fans 2. Blowers 3. AC Fans 4. Office Machines 5. Small Centrifugal Pumps 6. Home Appliances 7. Door Operators 8. Oil Burners 9. Poultry Feeders 10. Attic Fans 11. Furnace Blowers 12. Small Tools 13. Lathes |

Capacitor Start, Single Phase | 1/6 to 10 HP | 850, 1140, 1725, 3450 | 1. Improved efficiency vs. split phase 2. Typically used in belt drive applications 3. Capacitor Required 4. Available in single voltage and dual voltage 5. Generally reversible rotation 6. High starting torque | 1. Compressors 2. Conveyors 3. Pumps 4. Augers 5. Machine Tools 6. Grain Stirrers 7. Ventilation Fans 8. Food Equipment 9. Barn Cleaners 10. Vacuum Pumps 11. Manure Pumps 12. Milk Coolers 13. Elevators 14. Cattle Feeders |

Three Phase | 1/4 HP and Up | 850, 1140, 1725, 3450 | 1. High to Premium efficiency 2. Used in belt drive and direct drive applications 3. Three-phase power required 4. Typically, dual voltage 5. Generally reversible rotation 6. High starting torque | 1. Compressors 2. Conveyors 3. Pumps 4. Augers 5. Machine Tools 6. Grain Stirrers 7. Ventilation Fans 8. Food Equipment 9. Barn Cleaners 10. Vacuum Pumps 11. Manure Pumps 12. Milk Coolers 13. Elevators 14. Cattle Feeders 15. Drying Fans 16. Gear Motors |

Tip: In many cases, a PSC motor can replace a shaded pole motor, and a capacitor start motor can replace a split phase motor, assuming the other key characteristics are met.

Environmental Considerations

Select the motor type based on the operating environment.

Environment | Motor Type | Description |

|---|---|---|

Clean, Dry, Indoor, Non-Hazardous | OAO Open Air Over | Vent openings in the shell and/or end shields must be located in the air stream to provide motor cooling. |

ODP Open Drip Proof | Vent openings that are placed so that drops of liquid falling within an angle of 15 degrees from vertical will not affect performance. | |

Dirty, Damp, Outdoor, Non-Hazardous | TEFC Enclosed Fan Cooled | No vent openings in shell or end shield. Includes an external fan that blows cooling air over the motor frame. |

TENV Enclosed Non-Vented | No vent openings in shell or end shield. It depends on convection air for cooling. | |

TEAO Enclosed Air Over | No vent openings in shell or end shield. It depends on the airflow from the driven device for motor cooling. Must be loaded in the air stream. | |

Hazardous Explosion-Proof | TEFC/TENV | No vent openings in shell or end shields. Designed to withstand an internal explosion of specified gases or vapors and not allow the internal flame or explosion to escape. |

Tip: An enclosed motor can replace an open motor, assuming other characteristics meet the application requirements.

Mounting Selection

Resilient or Cradle Base

The motor is isolated from the base using rubber rings on the end shields.

Rigid or Footed Base

The base is welded or bolted directly to the motor shell for a solid, fixed installation.

Yoke Mount

Features welded tabs on the motor shell to allow bolting to a fan column or bracket.

C-Face Without Base

The motor's end shield has mounting holes.

C-Face With Base

The end shield has holes for mounting with a base.

Ring Mount

Includes rubber rings on each end shield with no base.

Stud Mount

Uses extended through-bolts (studs) for installation into brackets or tight spaces.

Other Key Specifications

Thermal Overload Protection

A temperature-sensing device shuts off the motor if it overheats due to overloading or failure to start.

Automatic Reset Thermal Overload Protector: Power restores once the motor cools. Avoid in hazardous restart situations.

Manual Reset Thermal Overload Protector: Requires push-button reset. Preferred for safety-critical tools and compressors.

If no thermal protection is present, the motor nameplate may say “none.”

Tip: Always match thermal protection with the motor being replaced.

Bearing Type

Bearings support the rotating parts of the motor. They are usually:

Sleeve Bearings: For light, fractional HP applications.

Ball Bearings: For higher load capacities and durability.

Service Factor

Indicates built-in overload capacity. Motors rated over 1.0 SF have more than a normal margin and are used where unusual conditions, such as occasional high or low voltage, momentary overloads, etc., are likely to occur.

Tip: Choose a service factor equal to or higher than the original motor.

Coatings

The insulation class refers to the class of insulation and related components used in the motor. These are rated by standard NEMA classifications according to the motor’s maximum operating temperatures.

Tips:

Keep in mind, each 10° C rise above the ratings can reduce the life of the motor by half.

Under normal conditions, a replacement motor should have a class equal to or higher than the original. If the replacement has a lower rating, it could cause premature failure.

CLASS | TOTAL TEMPERATURE OF SYSTEM |

|---|---|

A | 105°C (221°F) |

B | 130°C (266°F) |

F | 55°C (311°F) |

H | 180°C (356°F) |

(Maximum Allowable Operating Temperature)

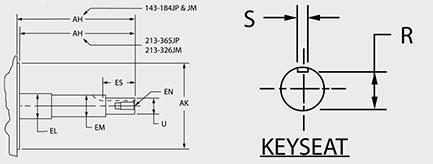

NEMA Frame Suffix Code Chart

C = Face Mount

H = Has a 2F dimension larger than the same frame without an H suffix

J = Face mount to fit jet pump

JM, JP = Face mount to fit close-coupled pumps

K = Has a hub for sump pump mounting

M = Flange mount for oil burner (5 1/2′′rabbet diameter)

N = Flange mount for oil burner (6 3/8′′ rabbet diameter)

T, TS = Integral HP motor dimension, NEMA standards set in 1964

U = Integral HP motor dimension, NEMA standards set in 1953

Y = Non-standard mounting, see manufacturer's drawing

Z = Non-standard shaft extension

Example: 56C – 56 (NEMA Frame Designation), C (NEMA Frame Suffix Code)

Tips:

If unsure of the frame size, measuring the shaft height is your best indicator to determine the frame size of the motor.

Letters in front of the frame size number are typically ignored (manufacturer-specific code).

Letters after the frame size number are important in selecting the correct replacement motor.

Motors with frame designation that include Y and Z after the frame size, in most cases, can be replaced with a standard motor. Measure the shaft and note the mounting method to compare with the replacement motor.

A 56Hz motor can be replaced by a 143T or 145T frame motor.

For detailed charts of shaft and mounting dimensions, see the NEMA Frame Dimension tables below.

JM Shaft

Frame | AH | U | EM | EL | EN | AK | Keyseat R | Keyseat S |

|---|---|---|---|---|---|---|---|---|

143 | 4 1/4 | 7/8 | 1 | 15/32 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

145 | 4 1/4 | 7/8 | 1 | 15/32 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

182 | 4 1/4 | 7/8 | 1 | 1 1/4 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

184 | 4 1/4 | 7/8 | 1 | 1 1/4 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

213 | 4 1/4 | 7/8 | 1 | 1 1/4 | 3/8-16 x.75 | 8 1/2 | 49/64 | 3/16 |

215 | 4 1/4 | 7/8 | 1 | 1 1/4 | 3/8-16 x.75 | 8 1/2 | 49/64 | 3/16 |

254 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 8 1/2 | 17/64 | 1/4 |

256 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 8 1/2 | 17/64 | 1/4 |

284 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

286 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

324 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

326 | 5 1/4 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

JP Shaft

Frame | AH | U | EM | EL | EN | AK | Keyseat R | Keyseat S |

|---|---|---|---|---|---|---|---|---|

143 | 75/16 | 7/8 | 1 | 15/32 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

145 | 75/16 | 7/8 | 1 | 15/32 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

182 | 75/16 | 7/8 | 1 | 1 1/4 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

184 | 75/16 | 1 1/4 | 1 | 1 1/4 | 3/8-16 x.75 | 4 1/2 | 49/64 | 3/16 |

213 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 3/8-16 x.75 | 8 1/2 | 17/64 | 1/4 |

215 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 3/8-16 x.75 | 8 1/2 | 17/64 | 1/4 |

254 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 8 1/2 | 17/64 | 1/4 |

256 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 8 1/2 | 17/64 | 1/4 |

284 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

286 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

324 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

326 | 81/8 | 1 1/4 | 1 3/8 | 1 3/4 | 1/2-13 x 1.00 | 12 1/2 | 17/64 | 1/4 |

364 | 81/8 | 1 5/8 | 1 3/4 | 2 1/8 | 1/2-13 x 1.00 | 12 1/2 | 113/32 | 3/8 |

365 | 81/8 | 1 5/8 | 1 3/4 | 2 1/8 | 1/2-13 x 1.00 | 12 1/2 | 113/32 | 3/8 |

Type C-Face AC Motors, Footed or Footless

BF Hole | BF Hole | BF Hole | Keyseat | Keyseat | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Frame Designation | AJ | AK | BA | BB Min. | BC | BD Max. | Number | Tap Size | Bolt Penetration Allowance | U | AH | R | S |

42C | 3 3/4 | 3 | 2 1/16 | 1/8 | -0.19 | 5 | 4 | 1/4-20 | - | 3/8 | 15/16 | 21/64 | flat |

48C | 3 3/4 | 3 | 2 1/2 | 1/8 | -0.19 | 5 5/8 | 4 | 1/4-20 | - | 1/2 | 1 11/16 | 29/64 | flat |

56C | 5 7/8 | 4 1/2 | 2 3/4 | 1/8 | -0.19 | 6 1/2 | 4 | 3/8-16 | - | 5/8 | 2 1/16 | 33/64 | 3/16 |

143TC & 145TC | 5 7/8 | 4 1/2 | 2 3/4 | 1/8 | 0.12 | 6 1/2 | 4 | 3/8-16 | 9/16 | 7/8 | 2 1/8 | 49/64 | 3/16 |

182TC & 184TC | 7 1/4 | 8 1/2 | 3 1/2 | 1/4 | +0.12 | 9 | 4 | 1/2-13 | 3/4 | 1 1/8 | 2 5/8 | 63/64 | 1/4 |

182TCH & 184TCH | 5 7/8 | 8 1/2 | 3 1/2 | 1/8 | +0.12 | 6 1/2 | 4 | 3/8-16 | 9/16 | 1 1/8 | 2 5/8 | 63/64 | 1/4 |

213TC & 215TC | 7 1/4 | 4 1/2 | 4 1/4 | 1/4 | +0.12 | 9 | 4 | 1/2-13 | 3/4 | 1 3/8 | 3 1/8 | 5/16 | 5/16 |

254TC & 256TC | 7 1/4 | 8 1/2 | 4 3/4 | 1/4 | +0.25 | 10 | 4 | 1/2-13 | 3/4 | 1 5/8 | 3 3/4 | 113/32 | 3/8 |

284TC & 286TC | 9 | 8 1/2 | 4 3/4 | 1/4 | +0.25 | 11 1/4 | 4 | 1/2-13 | 3/4 | 1 7/8 | 4 3/8 | 119/32 | 1/2 |

284TSC & 286TSC | 9 | 10 1/2 | 4 3/4 | 1/4 | +0.25 | 11 1/4 | 4 | 1/2-13 | 3/4 | 1 5/8 | 3 | 113/32 | 3/8 |

324TC & 326TC | 11 | 10 1/2 | 5 1/4 | 1/4 | +0.25 | 14 | 4 | 5/8-11 | 15/16 | 2 1/8 | 5 | 127/32 | 1/2 |

324TSC & 326TSC | 11 | 12 1/2 | 5 1/4 | 1/4 | +0.25 | 14 | 4 | 5/8-11 | 15/16 | 1 7/8 | 3 1/2 | 119/32 | 1/2 |

364TC & 365TC | 11 | 12 1/2 | 5 7/8 | 1/4 | +0.25 | 14 | 4 | 5/8-11 | 15/16 | 2 3/8 | 5 5/8 | 21/64 | 5/8 |

364TSC & 365TSC | 11 | 12 1/2 | 5 7/8 | 1/4 | +0.25 | 14 | 8 | 5/8-11 | 15/16 | 1 7/8 | 3 1/2 | 119/32 | 1/2 |

404TC & 405TC | 11 | 12 1/2 | 6 5/8 | 1/4 | +0.25 | 15 1/2 | 8 | 5/8-11 | 15/16 | 2 7/8 | 7 | 229/64 | 3/4 |

404TSC & 405TSC | 11 | 12 1/2 | 6 5/8 | 1/4 | +0.25 | 15 1/2 | 8 | 5/8-11 | 15/16 | 2 1/8 | 4 | 127/32 | 1/2 |

444TC & 445TC | 14 | 16 | 7 1/2 | 1/4 | +0.25 | 18 | 8 | 5/8-11 | 15/16 | 3 3/8 | 8 1/4 | 27/8 | 7/8 |

444TSC & 445TSC | 14 | 16 | 7 1/2 | 1/4 | +0.25 | 18 | 8 | 5/8-11 | 15/16 | 2 3/8 | 4 1/2 | 121/64 | 5/8 |

447TC & 449TC | 14 | 16 | 7 1/2 | 1/4 | +0.25 | 18 | 8 | 5/8-11 | 15/16 | 3 3/8 | 8 1/4 | 27/8 | 7/8 |

447TSC & 449TSC | 14 | 16 | 7 1/2 | 1/4 | +0.25 | 18 | 8 | 5/8-11 | 15/16 | 2 3/8 | 4 1/2 | 121/64 | 5/8 |

5000 Frame Series | 14 1/2 | 16 1/2 | - | 1/4 | +0.25 | 18 | 4 | 5/8-11 | 15/16 | - | - | - | - |

AC Foot-Mounted Motors with Single Straight Shaft Extension

Frame Designation | A Max. | D | E | 2F | BA | H | U | N-W | V Min. | Keyseat R | Keyseat S | AA Min. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

42 | - | 2 5/8 | 1 3/4 | 1 11/16 | 2 1/16 | 9/32 slot | 3/8 | 1 1/8 | - | 2 1/64 | flat | - |

48 | - | 3 | 2 1/8 | 2 3/4 | 2 1/2 | 11/32 slot | 1/2 | 1 1/2 | - | 29/64 | flat | - |

48H | - | 3 | 2 1/8 | 4 3/4 | 2 1/2 | 11/32 slot | 1/2 | 1 1/2 | - | 29/64 | flat | - |

56 | - | 3 1/2 | 2 7/16 | 3 | 2 3/4 | 11/32 slot | 5/8 | 1 7/8 | - | 33/64 | 3/16 | - |

56H | - | 3 1/2 | 2 7/16 | 5 | 2 3/4 | 11/32 slot | 5/8 | 1 7/8 | - | 33/64 | 3/16 | - |

143T | 7 | 3 1/2 | 2 3/4 | 4 | 2 1/4 | 11/32 hole | 7/8 | 2 1/4 | 2 | 49/64 | 3/16 | 3/4 |

145T | 7 | 3 1/2 | 2 3/4 | 5 | 2 1/4 | 11/32 hole | 7/8 | 2 1/4 | 2 | 49/64 | 3/16 | 3/4 |

182 | 9 | 4 1/2 | 3 3/4 | 4 1/2 | 2 3/4 | 13/32 hole | 7/8 | 2 1/4 | 2 | 49/64 | 3/16 | 3/4 |

184 | 9 | 4 1/2 | 3 3/4 | 5 1/2 | 2 3/4 | 13/32 hole | 7/8 | 2 1/4 | 2 | 49/64 | 3/16 | 3/4 |

182T | 9 | 4 1/2 | 3 3/4 | 4 1/2 | 2 3/4 | 13/32 hole | 1 1/8 | 2 3/4 | 2 1/2 | 63/64 | 2 1/2 | 3/4 |

184T | 9 | 4 1/2 | 3 3/4 | 5 1/2 | 2 3/4 | 13/32 hole | 1 1/8 | 2 3/4 | 2 1/2 | 63/64 | 2 1/2 | 3/4 |

213 | 10 1/2 | 5 1/4 | 4 1/4 | 5 1/2 | 3 1/2 | 13/32 hole | 1 1/8 | 3 | 2 3/4 | 63/64 | 2 1/2 | 3/4 |

215 | 10 1/2 | 5 1/4 | 4 1/4 | 7 | 3 1/2 | 13/32 hole | 1 1/8 | 3 | 2 3/4 | 63/64 | 2 1/2 | 3/4 |

213T | 10 1/2 | 5 1/4 | 4 1/4 | 5 1/2 | 3 1/2 | 13/32 hole | 1 3/8 | 3 3/8 | 3 1/8 | 1 13/64 | 5/16 | 1 |

215T | 10 1/2 | 5 1/4 | 4 1/4 | 7 | 3 1/2 | 13/32 hole | 1 3/8 | 3 3/8 | 3 1/8 | 1 13/64 | 5/16 | 1 |

254U | 12 1/2 | 6 1/4 | 5 | 8 1/4 | 4 1/4 | 17/32 hole | 1 3/8 | 3 3/4 | 3 1/2 | 1 13/64 | 5/16 | 1 |

256U | 12 1/2 | 6 1/4 | 5 | 10 | 4 1/4 | 17/32 hole | 1 3/8 | 3 3/4 | 3 1/2 | 1 13/64 | 5/16 | 1 |

254T | 12 1/2 | 6 1/4 | 5 | 8 1/4 | 4 1/4 | 17/32 hole | 1 5/8 | 4 | 3 3/4 | 1 13/32 | 3/8 | 1 1/4 |

256T | 12 1/2 | 6 1/4 | 5 | 10 | 4 1/4 | 17/32 hole | 1 5/8 | 4 | 3 3/4 | 1 13/32 | 3/8 | 1 1/4 |

284U | 14 | 7 | 5 1/2 | 9 1/2 | 4 3/4 | 17/32 hole | 1 5/8 | 4 7/8 | 4 5/8 | 1 13/32 | 3/8 | 1 1/4 |

286U | 14 | 7 | 5 1/2 | 11 | 4 3/4 | 17/32 hole | 1 5/8 | 4 7/8 | 4 5/8 | 1 13/32 | 3/8 | 1 1/4 |

284T | 14 | 7 | 5 1/2 | 9 1/2 | 4 3/4 | 17/32 hole | 1 5/8 | 4 5/8 | 4 3/8 | 1 19/32 | 1/2 | 1 1/2 |

286T | 14 | 7 | 5 1/2 | 11 | 4 3/4 | 17/32 hole | 1 5/8 | 4 5/8 | 4 3/8 | 1 19/32 | 1/2 | 1 1/2 |

284TS | 14 | 7 | 5 1/2 | 9 1/2 | 4 3/4 | 17/32 hole | 1 5/8 | 3 1/4 | 3 | 1 13/32 | 3/8 | 1 1/2 |

286TS | 14 | 7 | 5 1/2 | 11 | 4 3/4 | 17/32 hole | 1 5/8 | 3 1/4 | 3 | 1 13/32 | 3/8 | 1 1/2 |

324U | 16 | 8 | 6 1/4 | 10 1/2 | 5 1/4 | 21/32 hole | 1 7/8 | 5 5/8 | 5 3/8 | 1 19/32 | 1/2 | 1 1/2 |

326U | 16 | 8 | 6 1/4 | 12 | 5 1/4 | 21/32 hole | 1 7/8 | 5 5/8 | 5 3/8 | 1 19/32 | 1/2 | 1 1/2 |

324US | 16 | 8 | 6 1/4 | 10 1/2 | 5 1/4 | 21/32 hole | 1 5/8 | 3 1/4 | 3 | 1 13/32 | 3/8 | 1 1/2 |

326US | 16 | 8 | 6 1/4 | 12 | 5 1/4 | 21/32 hole | 1 5/8 | 3 1/4 | 3 | 1 13/32 | 3/8 | 1 1/2 |

324T | 16 | 8 | 6 1/4 | 10 1/2 | 5 1/4 | 21/32 hole | 2 1/8 | 5 1/4 | 5 | 1 27/32 | 1/2 | 2 |

326T | 16 | 8 | 6 1/4 | 12 | 5 1/4 | 21/32 hole | 2 1/8 | 5 1/4 | 5 | 1 27/32 | 1/2 | 2 |

324TS | 16 | 8 | 6 1/4 | 10 1/2 | 5 1/4 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 2 |

326TS | 16 | 8 | 6 1/4 | 12 | 5 1/4 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 2 |

364U | 18 | 9 | 7 | 11 1/4 | 5 7/8 | 21/32 hole | 2 1/8 | 6 3/8 | 6 1/8 | 1 27/32 | 1/2 | 2 |

365U | 18 | 9 | 7 | 12 1/4 | 5 7/8 | 21/32 hole | 2 1/8 | 6 3/8 | 6 1/8 | 1 27/32 | 1/2 | 2 |

364US | 18 | 9 | 7 | 11 1/4 | 5 7/8 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 2 |

365US | 18 | 9 | 7 | 12 1/4 | 5 7/8 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 2 |

364T | 18 | 9 | 7 | 11 1/4 | 5 7/8 | 21/32 hole | 2 3/8 | 5 7/8 | 5 5/8 | 2 1/64 | 5/8 | 3 |

365T | 18 | 9 | 7 | 12 1/4 | 5 7/8 | 21/32 hole | 2 3/8 | 5 7/8 | 5 5/8 | 2 1/64 | 5/8 | 3 |

364TS | 18 | 9 | 7 | 11 1/4 | 5 7/8 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 3 |

365TS | 18 | 9 | 7 | 12 1/4 | 5 7/8 | 21/32 hole | 1 7/8 | 3 3/4 | 3 1/2 | 1 19/32 | 1/2 | 3 |

404U | 20 | 10 | 8 | 12 1/4 | 6 5/8 | 26/32 hole | 2 3/8 | 7 1/8 | 6 7/8 | 2 1/64 | 5/8 | 2 |

Frame Designation | A Max. | D | E | 2F | BA | H | U | N-W | V Min. | Keyseat R | Keyseat S | AA Min. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

405U | 20 | 10 | 8 | 13 3/4 | 6 5/8 | 26/32 hole | 2 3/8 | 7 1/8 | 6 7/8 | 2 1/64 | 5/8 | 2 |

404US | 20 | 10 | 8 | 12 1/4 | 6 5/8 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 7/8 | 1/2 | 2 |

405US | 20 | 10 | 8 | 13 3/4 | 6 5/8 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 7/8 | 1/2 | 2 |

404T | 20 | 10 | 8 | 13 3/4 | 6 5/8 | 26/32 hole | 2 7/8 | 7 1/4 | 7 | 2 29/64 | 3/4 | 3 |

405T | 20 | 10 | 8 | 12 1/4 | 6 5/8 | 26/32 hole | 2 7/8 | 7 1/4 | 7 | 2 29/64 | 3/4 | 3 |

404TS | 20 | 10 | 8 | 13 3/4 | 6 5/8 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 27/32 | 1/2 | 3 |

405TS | 20 | 10 | 8 | 12 1/4 | 6 5/8 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 27/32 | 1/2 | 3 |

444U | 22 | 11 | 9 | 13 3/4 | 7 1/2 | 26/32 hole | 2 7/8 | 8 5/8 | 8 3/8 | 2 29/64 | 3/4 | 2 1/2 |

445U | 22 | 11 | 9 | 14 1/2 | 7 1/2 | 26/32 hole | 2 7/8 | 8 5/8 | 8 3/8 | 2 29/64 | 3/4 | 2 1/2 |

444US | 22 | 11 | 9 | 16 1/2 | 7 1/2 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 27/32 | 1/2 | 2 1/2 |

445US | 22 | 11 | 9 | 14 1/2 | 7 1/2 | 26/32 hole | 2 1/8 | 4 1/4 | 4 | 1 27/32 | 1/2 | 2 1/2 |

444T | 22 | 11 | 9 | 16 1/2 | 7 1/2 | 26/32 hole | 3 3/8 | 8 1/2 | 8 1/4 | 2 7/8 | 7/8 | 3 |

445T | 22 | 11 | 9 | 14 1/2 | 7 1/2 | 26/32 hole | 3 3/8 | 8 1/2 | 8 1/4 | 2 7/8 | 7/8 | 3 |

447T | 22 | 11 | 9 | 16 1/2 | 7 1/2 | 26/32 hole | 3 3/8 | 8 1/2 | 8 1/4 | 2 7/8 | 7/8 | 3 |

449T | 22 | 11 | 9 | 20 | 7 1/2 | 26/32 hole | 3 3/8 | 8 1/2 | 8 1/4 | 2 7/8 | 7/8 | 3 |

444TS | 22 | 11 | 9 | 25 | 7 1/2 | 26/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | 3 |

445TS | 22 | 11 | 9 | 14 1/2 | 7 1/2 | 26/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | 3 |

447TS | 22 | 11 | 9 | 16 1/2 | 7 1/2 | 26/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | 3 |

449TS | 22 | 11 | 9 | 20 | 7 1/2 | 26/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | 3 |

5004 | 25 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 3 7/8 | 11 5/8 | 11 1/4 | 3 5/16 | 1 | - |

5004G | 25 | 12 1/2 | 10 | 16 | 8 1/2 | 30/32 hole | 3 1/2 | 10 1/2 | 10 2/8 | 3 | 7/8 | - |

5004S | 25 | 12 1/2 | 10 | 16 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5004SS | 25 | 12 1/2 | 10 | 16 | 8 1/2 | 30/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | - |

5006L | 28 1/2 | 12 1/2 | 10 | 16 | 8 1/2 | 30/32 hole | 4 7/8 | 14 5/8 | 14 3/8 | 4 11/64 | 1 1/4 | - |

5006S | 28 1/2 | 12 1/2 | 10 | 20 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5006MS | 28 1/2 | 12 1/2 | 10 | 20 | 8 1/2 | 30/32 hole | 3 3/8 | 6 3/4 | 6 1/2 | 2 7/8 | 7/8 | - |

5008 | 25 | 12 1/2 | 10 | 20 | 8 1/2 | 30/32 hole | 3 7/8 | 11 5/8 | 11 1/4 | 3 5/16 | 1 | - |

5008G | 25 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 3 1/2 | 10 1/2 | 10 2/8 | 3 | 7/8 | - |

5008L | 28 1/2 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 4 7/8 | 14 5/8 | 14 3/8 | 4 11/64 | 1 1/4 | - |

5008S | 25 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5008S | 28 1/2 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5008MS | 28 1/2 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 3 3/8 | 6 3/4 | 6 1/2 | 2 56/64 | 7/8 | - |

5008SS | 25 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | - |

5008SS | 28 1/2 | 12 1/2 | 10 | 25 | 8 1/2 | 30/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | - |

5010L | 28 1/2 | 12 1/2 | 10 | 32 | 8 1/2 | 30/32 hole | 4 7/8 | 14 5/8 | 14 3/8 | 4 11/64 | 1 1/4 | - |

5010S | 28 1/2 | 12 1/2 | 10 | 32 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5010MS | 28 1/2 | 12 1/2 | 10 | 32 | 8 1/2 | 30/32 hole | 3 3/8 | 6 3/4 | 6 1/2 | 2 7/8 | 7/8 | - |

5010SS | 28 1/2 | 12 1/2 | 10 | 32 | 8 1/2 | 30/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | - |

5012L | 28 1/2 | 12 1/2 | 10 | 40 | 8 1/2 | 30/32 hole | 4 7/8 | 14 5/8 | 14 3/8 | 4 11/64 | 1 1/4 | - |

5012S | 28 1/2 | 12 1/2 | 10 | 40 | 8 1/2 | 30/32 hole | 2 7/8 | 5 3/4 | 5 1/2 | 2 29/64 | 3/4 | - |

5012MS | 28 1/2 | 12 1/2 | 10 | 40 | 8 1/2 | 30/32 hole | 3 3/8 | 6 3/4 | 6 1/2 | 2 7/8 | 7/8 | - |

5012SS | 28 1/2 | 12 1/2 | 10 | 40 | 8 1/2 | 30/32 hole | 2 3/8 | 4 3/4 | 4 1/2 | 2 1/64 | 5/8 | - |

Why Choose NEMA Premium® Efficiency Motors?

NEMA (National Electrical Manufacturers Association), along with electric motor member companies, established a NEMA Premium® energy efficiency motors program to provide highly energy efficient products that meet the needs and applications of users based on a consensus definition of ′′premium efficiency′′ and use of the NEMA Premium® logo for premium products.

Choosing a motor with the NEMA Premium® logo will identify higher efficiency motors that will save money in total energy operating cost and improve system reliability.

For more information about the NEMA Premium® efficiency motor program, go to https://www.nema.org/membership/products/nema-premium-motors.