A micrometer is a precision measuring tool used to measure small distances with extremely high accuracy. Commonly used in mechanical engineering and machining, micrometers are designed to measure the thickness, diameter, or length of small parts. There are different types of micrometers, but outside micrometers are the most commonly used for measuring the outside diameter (OD) or thickness of objects.

What Is a Micrometer?

Understand It. Use It. Measure with Confidence. Your Complete Guide to Outside Micrometers Starts Here.

What Is a Micrometer?

Outside micrometers are industry-standard tools because of their high accuracy/resolution and ease of use. They are available in a variety of spindle and anvil configurations to allow the operator to measure difficult-to-reach features on a workpiece.

Essential Tip

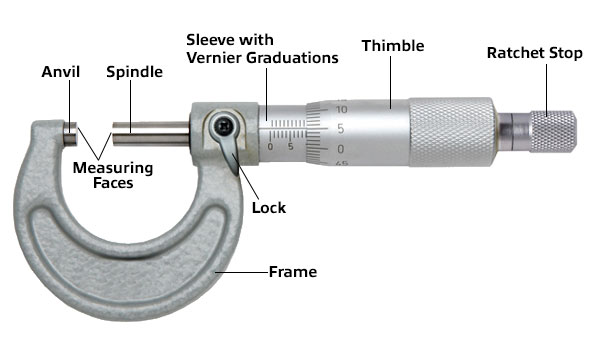

To ensure accurate measurements, the measuring faces of a micrometer, specifically the anvil and spindle, must be both flat and parallel. These surfaces are typically faced with durable carbide to resist wear from frequent use. In some cases, hardened steel is used as a cost-effective alternative, though it may not offer the same longevity.

Types of Outside Micrometers

Electronic Outside Micrometers

Electronic outside micrometers are digital measuring tools that typically measure in increments of 0–0.25 millimeters (0–1 inches). They feature an easy-to-read digital (LCD) display that allows users to switch between inch and metric units and set the reading to zero at any position. These micrometers are also available in sets.

Mechanical Outside Micrometers

Mechanical outside micrometers, also known as micrometers, mics, or screw gages, measure ranges from 0" to 20", engineered in 1" increments. They are graduated in 0.001" and often include a 0.0001" vernier scale for higher precision. Metric versions with corresponding graduations are also available. Mechanical micrometers are offered individually or as part of a set.

Measuring Range & Accuracy

Outside micrometers come in a variety of spindle and anvil configurations, allowing operators to measure hard-to-reach features on a workpiece. A standard OD micrometer typically covers a 1" (25mm) measuring range. However, special-application micrometers may have smaller or larger ranges. Wide-range OD micrometers, also known as interchangeable anvil micrometers, offer extended measurement capabilities while reducing the overall cost compared to purchasing multiple individual micrometers. These usually cover up to a 6" range.

Micrometer standards are used to verify (but not calibrate) the zero position of a micrometer when the spindle does not contact the anvil. This is especially important for micrometers over 1" (25mm) and certain specialty models.

Essential Tip

The accuracy of a micrometer depends on several key factors:

Thread accuracy: Precision-ground threads on the spindle ensure consistent, fine movement.

Flatness of measuring faces: Both the anvil and spindle faces must be perfectly flat to avoid distorted readings.

Parallelism between the faces: The anvil and spindle must remain parallel under measurement pressure.

Rigidity of the frame that holds the anvil and spindle: A stable, well-constructed frame prevents flexing, which could compromise measurement accuracy.

How to Read a Micrometer

The high accuracy and resolution of a micrometer come from the precision-ground threads on its spindle. In a standard English micrometer, the spindle uses 40 threads per inch (TPI). Each full revolution of the spindle moves the measuring face by 0.025 inches.

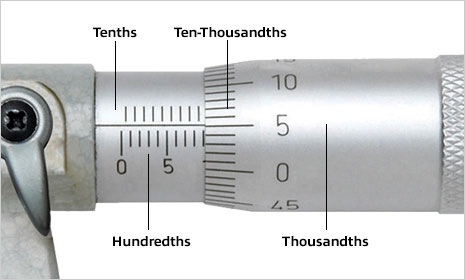

Sleeve Graduations:

The sleeve is marked in 0.025" increments. It is divided into 40 equal parts, each represented by a vertical line. Every fourth line is longer and numbered: "1" indicates 0.100", "2" indicates 0.200", and so on.

Thimble Graduations:

The thimble is divided into 25 equal parts, with each division representing 0.001". One full rotation of the thimble aligns with a 0.025" movement on the sleeve.

Vernier Scale (for 0.0001" readings):

To read to one ten-thousandth requires an additional scale called the Vernier scale. In the case of a regular micrometer, the vernier consists of 10 divisions spaced across 9 divisions of the thimble. This allows the user to read measurements to the nearest 0.0001".

Note: To take an accurate measurement, align the thimble with the sleeve and, if applicable, use the vernier scale to refine your reading.

Types of Micrometer Thimbles

Ingress Protection Standard (IP Ratings)

Some outside micrometers are rated with an IP (Ingress Protection) code, which indicates their resistance to dust, debris, and liquids, particularly in environments where coolant spray or fine particulates are common, such as machine tool operations.

An IP rating consists of two digits:

The first digit indicates the level of protection against solid particles like dust.

The second digit represents protection against liquids, including coolant and water spray.