Pipe Taps cut internal threads in parts or fittings that will make a pressure-tight joint once they’re mated with threaded pipe or fittings. Requiring 100% thread depth, pipe threads need higher cutting forces than regular machine thread tapping. Most threads on tapered pipe taps are cutting.

Pipe Tap Diagrams and Applications

Discover the correct types, styles, materials, and finishes for your workpiece. Diagrams clearly outline the traits of pipe taps to help you select the right one for the job.

Diagram of a Pipe Tap

Essential Tips

Types of Pipe Taps

Standard Pipe Taps

For cutting internal threads in parts or fittings that will then be mated with threaded pipe or fittings to create pressure-tight joints.

Extension Pipe Taps

For internal deep-hole drilling of pipes and pipe fittings. Designed with both interrupted and standard threads, they are ideal for hard-to-reach areas in general-purpose applications.

Interrupted Thread Pipe Taps

Feature a tooth removed on each cutting edge to reduce friction and increase chip flow. They are for general-purpose applications on both ferrous and nonferrous materials. Typically, this kind of pipe tap has an odd number of threads.

Spiral Flute Pipe Taps

For general-purpose internal threading of pipe taps and fittings. The flute geometry draws the chips away from the hole, where chip disposal may be an issue. Spiral flute short projection pipe tap designs are available for shallow-hole applications.

Thread-Forming Pipe Taps

For forming internal threads by displacing the metal without producing chips in pipes and fittings. They are ideal for aluminum, brass, copper, steel, and soft metals.

British Standard Pipe Taps

For cutting internal threads in parts or fittings. They interconnect and seal pipe ends by mating an external with an internal thread, resulting in a pressure-tight joint.

Thread Standards

NPT (National Pipe Taper) refers to American National Standard Taper Pipe Threads. Commonly used for general-purpose applications, they do require a sealant.

NPS (National Pipe Straight) refers to American National Standard Straight Pipe. They are typically used for threads in pipe couplings.

NPSF (National Pipe Straight-Fuel) refers to Dryseal American National Standard Fuel Internal Straight Pipe Threads.

NPTF (National Pipe Taper Fuel) refers to Dryseal American National Standard Tapered Pipe Threads. They do not require a sealant, since they’re formed by metal-to-metal contact. They are straight internal threads for assembly with NPTF external threads.

BSPF (British Standard Pipe Fitting) refers to an older designation that’s been replaced by the G series. They are for internal or external threads, where the seal is not on the thread.

BSPP (British Internal Straight Parallel Pipe Threads) are typically for mechanical joints.

BSPRP pipe threads are for general-purpose fastening and mechanical assemblies. They do not meet the requirement for pipe threads where pressure-tight joints are made of threads.

BSPT (British Internal Tapered Parallel Pipe Threads) refers to full-form threads used for pressure-tight joints.

PTF-SAE refers to short internal threads. They are for couplings and fittings where a shorter length of engagement is required.

Thread Sizes

NPT & NPS Pipe Tap Thread Length Examples

Thread Size | Thread Length (In.) |

|---|---|

1/16-27 | 1-1/16 |

1/8-27S | 3/4 |

1/8-27 | 3/4 |

1/4-18 | 1-1/16 |

3/18-18 | 1-1/16 |

1/2-14 | 1-3/8 |

3/4-14 | 1-3/8 |

1-11-1/2 | 1-3/4 |

1-1/4-11-1/2 | 1-3/4 |

1-1/2-11-1/2 | 1-3/4 |

2-11-1/2 | 1-3/4 |

Tap Drill Size Examples

Thread Size | NPT Drill Size | NPS Drill Size |

|---|---|---|

1/16-27 | D | 1/4 |

1/8-27 | R | S |

1/4-18 | 7/16 | 29/64 |

3/8-18 | 37/64 | 19/32 |

1/2-14 | 23/32 | 47/64 |

3/4-14 | 59/64 | 15/16 |

1-11-1/2 | 1-5/32 | 1-3/16 |

1-1/4-11-1/2 | 1-1/2 | 1-33/64 |

1-1/2-11-1/2 | 1-47/64 | 1-3/4 |

2-11-1/2 | 2-7/32 | 2-7/32 |

Standard Finishes

Bright options provide a smooth, polished finish on the tool. This increases chip flow in softer materials such as aluminum, wood, and plastic.

Nitride is a thin, hard shell coating that supports the surface hardness of the tool. It is common where abrasive or wearing conditions exist.

Oxide is also known as black oxide or steam oxide. This surface treatment prevents chip building, galling, and welding on the workpiece. It’s a common choice for working on stainless steel and low-carbon or ferrous metals.

Titanium Nitride (TiN) is a multi-purpose coating that increases chip flow in softer materials. The heat and hardness resistance allow the tool to run at higher speeds than uncoated tools.

Titanium Carbon Nitride (TiCN) is harder and more wear-resistant than TiN. It is common when working on stainless steel, cast iron, and aluminum alloy.

TiCN PLUS is Titanium Carbon-Nitride (TiCN) combined with Titanium Nitride (TiN). This all-purpose finish increases tool life by two to four times more than TiN-coated options. The heat and hardness resistance allow equipment to run at higher speeds than uncoated tools.

Materials

Hook Styles

Several pipe taps feature a hook, which is the entry angle of the cutting face or the part of the flute that cuts into the workpiece.

High-hook pipe taps are for use with ductile materials that normally produce long, continuous chips. Examples include aluminum, free machining stainless steel, mild steels, and plastics.

Medium-hook, also known as regular-hook, pipe taps produce smaller chips in general-purpose applications. They are for use on a variety of ferrous and nonferrous metals.

Low-hook pipe taps produce granular chips. They are for use on cast iron and brass.

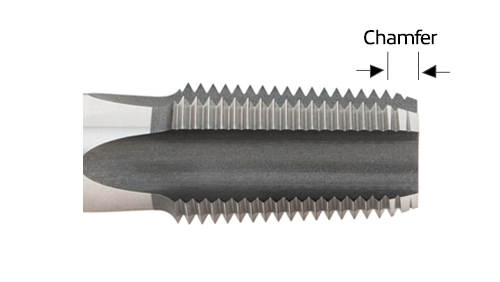

Chamfer Styles

Extension Pipe Taps and British Standard Pipe Taps typically feature a chamfer. Chamfers are the length of the tapering threads at the front of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part.

Plug chamfers are the most common style that efficiently threads blind and through holes. They have 3 to 5 chamfer threads.

Bottoming chamfers are for threading blind holes to the bottom. They have 1 to 2 chamfer threads.

Taper chamfers are known as a starter tap. They have a longer chamfer and require a less aggressive cutting action. They have 7 to 10 chamfer threads.

Spiral point plug chamfers are for general-purpose applications. They have 4 to 5 chamfer threads.