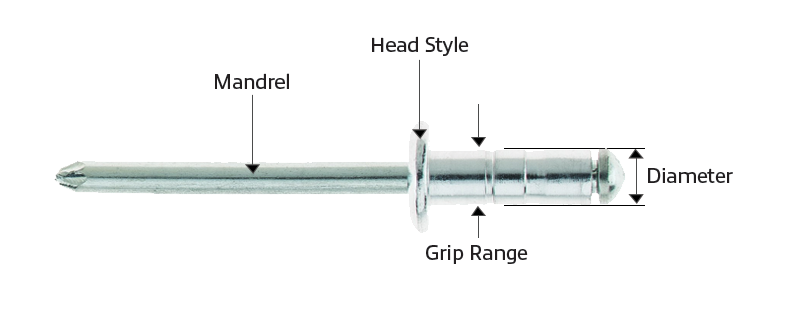

Blind rivets are one of the most common types of rivets, especially when access to only one side of the workpiece is possible. They contain a mandrel through the center that, when pulled with a rivet tool, causes the rivet body to expand and secure the materials together. Once fully set, the mandrel snaps off, leaving a clean, permanent joint. Blind rivets are common in automotive, aerospace, electronics, and industrial manufacturing because they offer a quick, reliable alternative to welding. Rivet assortments are also available.

A Fastener That Holds Up

Explore the different types of rivets, head styles, and materials to find long-lasting fastening solutions.

Blind rivets

Essential Tip

Blind rivets are typically measured by two key dimensions: body diameter and grip range. The grip range refers to the total thickness of the materials being fastened with the rivet. To ensure a secure hold, the grip range should always be less than the length of the rivet body.

Rivet Strengths

Before selecting a rivet, it is important to determine the shear strength and tensile strength required for your application:

Shear strength is the force/load a rivet can withstand when materials move in opposite directions, perpendicular to the rivet.

Tensile strength is the force/load required to pull the joined materials apart along the rivet’s axis.

Additional factors such as rivet style, material, diameter, and fastener spacing also affect the ability of a rivet to hold the material properly.

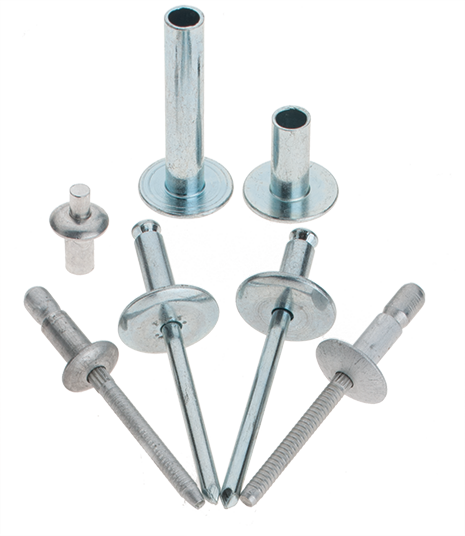

Types of Rivets

Closed-End Rivets

Closed-end blind rivets have a cup-shaped design that creates a tight seal, preventing the entry of liquids or air. Ideal for watertight applications, they offer high shear and tensile strength and enhanced mandrel protection.

Colored Rivets

These rivets are coated or color-coded based on material type for easy identification.

Drive Rivets

Drive rivets feature a short mandrel and are installed by striking with a hammer. They offer fast installation for materials that don't require access to both sides.

Flush Rivets

Flush blind rivets sit flat on both sides of the workpiece and are used in countersunk holes, making them ideal for applications with minimal clearance.

Lockbolt Rivets

Lockbolt rivets include a locking groove system for extra strength in high-vibration environments. They form a permanent, tamper-resistant bond.

Multi Grip Rivets

These rivets feature a wide grip range to accommodate various hole sizes. They are ideal for oversized, irregular, or misaligned openings.

Structural Rivets with a Locking Stem

These heavy-duty rivets include a locking collar on the stem, providing a watertight and vibration-resistant bond.

Screw Mount Rivets

Screw mount rivets are reusable one-piece fasteners that have a pre-driven pin that quickly installs into a workpiece. They are vibration-resistant and ideal for low-to-medium applications.

Open End Rivets

Open-end blind rivets are ideal when access to only one side of the material is available, and disassembly isn’t required. They create a clean, low-profile finish.

Peel Rivets

Peel rivets split into four petals on the blind side that bend outward and secure to the back of the workpiece.

Plus Blind Rivets

Designed for soft, fragile, or thin materials, plus blind rivets are best in applications where only one side is accessible.

Push Mount Rivets

These rivets snap into predrilled holes with just finger pressure. The expanding legs hold the materials securely and can be released by pulling the head.

Structural Rivets

Structural blind rivets are for high-load, limited-access applications. They provide exceptional strength and resistance to corrosion and tampering.

Tri Folding Rivets

Tri-fold rivets expand into three legs behind the material to secure the rivet in place.

Rivet Head Types

Different types of rivets feature distinct head shapes, such as:

Brazier Head Rivets

Brazier head rivets have wide, shallow domes that provide a large bearing surface and a low profile. They are commonly used in aircraft and blind installations for their smooth appearance.

Button Head Rivets

Button heads are rounded on top with a flat bearing surface. They slightly protrude from the workpiece and are often chosen for aesthetic purposes.

Countersunk Head Rivets

Countersunk head rivets lie flush against the workpiece material and have large bearing surfaces. They are ideal for applications requiring a smooth finish or where clearance is limited.

Dome Head Rivets

Dome head types have domed, cylindrical heads with low profiles. They are commonly used for their large bearing surface and versatility.

Large-Flange Head Rivets

Large-flange rivets have the widest bearing surface of any blind rivet head. They are ideal for use in oversized holes or with soft, brittle materials to prevent pull-through.

Large-Flange Dome Head Rivets

These rivets combine a domed head with an extra-wide flange for added support in delicate or low-strength materials.

Protruding Head Rivets

Protruding heads extend slightly above the surface and provide a strong hold without fully embedding into the workpiece.

Rivet Heads

Rivet heads are typically protruding, cylindrical heads with large bearing surfaces.

Round Head Rivets

Round head rivets have a dome-shaped top with a flat bearing surface and a higher profile than other head types.

Truss Head Rivets

Truss head rivets feature low-profile heads that are slightly rounded. They have flat bearing surfaces that prevent pull-through and are ideal for low-clearance applications.

Universal Head Rivets

Universal rivets have a rounded, domed shape that protrudes slightly, combining the advantages of dome and button heads.

Rivet Materials

A rivet should be made of a material that is similar to or compatible with the materials being joined. It is also important to consider the environment where the finished product will be used, such as exposure to moisture, high temperatures, or corrosive conditions.

Aluminum has a high strength-to-weight ratio and is wear-resistant, nonmagnetic, and conductive. It is easier to form and machine than steel and is naturally corrosion-resistant. It is available in several grades and standards, including grade 11 and grade 19 specifications.

Nylon is a lightweight, nonconductive material that resists impact, wear, and abrasion. It is ideal for electrical applications or environments where corrosion is a concern.

Stainless steel is a strong, corrosion-resistant alloy with excellent heat resistance. It is suitable for high-stress, outdoor, and corrosive applications and is available in grade 50 and 51 specifications.

Steel is strong and durable, but it offers less corrosion resistance than stainless steel. Applying protective finishes or coatings can improve its corrosion resistance.

More Types of Rivets from MSC Industrial Supply

Panel Rivets

Panel rivets are push-in fasteners that resist vibration, loosening, abrasion, and movement. They are typically inserted into punched or predrilled holes in thin materials such as plastic, sheet metal, or composite panels. These rivets are ideal for securing lightweight components in electronics, appliances, and automotive interiors.

Solid Rivets

Solid rivets are one of the oldest and strongest types of rivets, used in structural applications where a permanent, high-strength joint is needed, such as bridge construction, shipbuilding, and aircraft assembly. They are installed through predrilled holes using a hammer or rivet gun to fasten multiple workpieces together.

Semi-Tubular and Split Rivets

1. Semi-tubular rivets feature a partially hollow shank that curls or buckles when set, requiring less force to install than solid rivets.

2. Split rivets have two legs that expand and grip the material once inserted.

Both types are ideal for fastening lightweight or soft materials such as leather, fiberboard, plastic, aluminum, and wood. They are commonly used in furniture, crafting, and light-duty mechanical assemblies.