Case Study: OSG HYPRO® CARB VGM5

A large brake manufacturer finds great results and savings with OSG's new HY-PRO® CARB VGM5 end mill.

A large brake manufacturer finds great results and savings with OSG's new HY-PRO® CARB VGM5 end mill.

A large brake manufacturer is struggling with cycle time while milling an A2 brake pad component.

The goal is to increase part production by improving cycle time and tool life.

OSG brought in the HYPRO® CARB VGM5 to take on the application. By utilizing a proper chipload with high efficiency milling (HEM), OSG was able to help the manufacturer have even wear on the cutting edge and better productivity while also increasing tool life.

The OSG HYPRO® CARB VGM5 performed above and beyond the competitor, increasing tool life from 4 parts to 14 per tool!

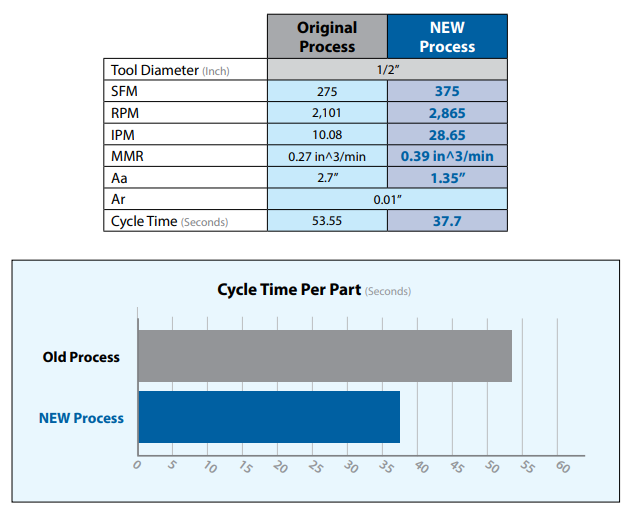

• SFM was increased from 275 to 375 due to utilizing HEM

• Feed per tooth was increased from 0.0012 to 0.002. This has greater effect due to OSG having 5 flutes vs the competitor’s 4

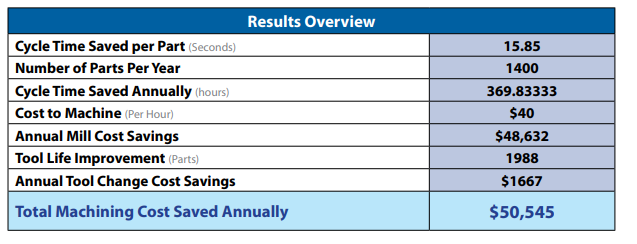

• Cycle time was reduced by 15.85 seconds per part (53.55 sec to 37.7 sec)

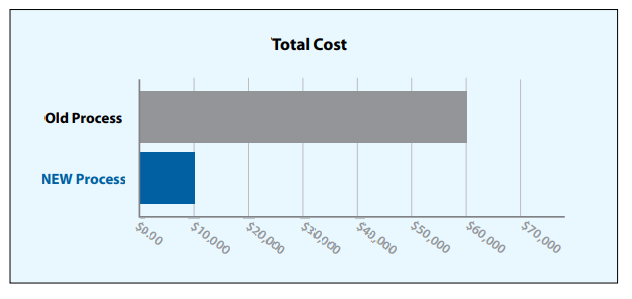

• A total savings of $50,545

Annual mill usage with OSG is now 100 vs. the old processes with 350 tools per year. This alone saves $48,632 per year with an overall savings of over $50,000!

Download a PDF of the Case Study here.

To learn more about OSG’s HY-PRO® CARB VGM end mills, visit MSCDirect.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.