Time was when milling required multiple tools to get the job done. Now Kennametal’s new HARVI I TE series with square and ball nose end mills is setting new performance standards. Here’s what you need to know about the new tool.

Kennametal’s newest addition to its HARVI I TE series of high-performance solid end milling tools is a big benefit for machinists who value productivity, tool life and versatility.

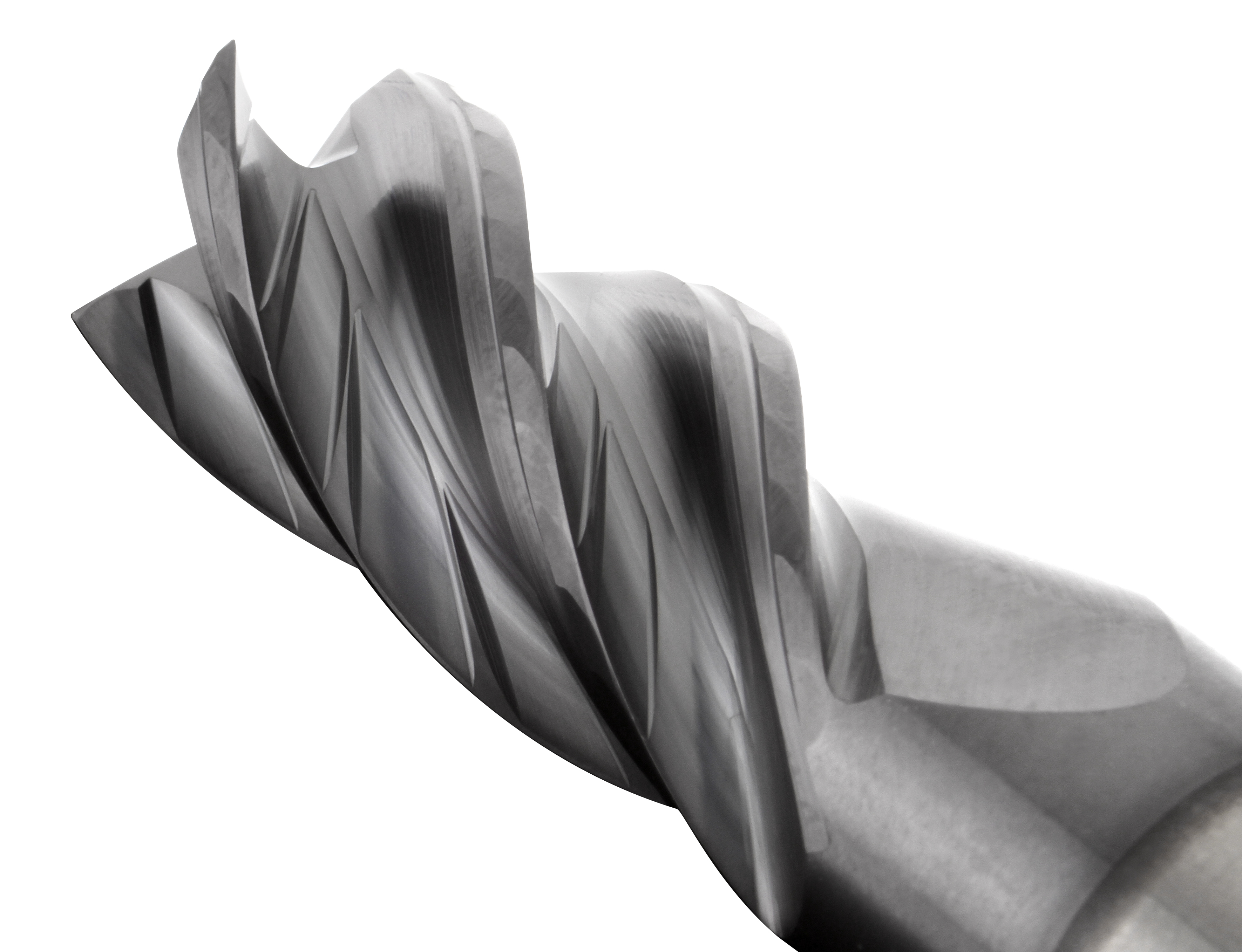

The HARVI I TE is a four-flute solid carbide end mill designed for versatility and highly productive roughing and finishing operations. The recently added ball nose version is ideal for any highly productive 3D operations.

Incorporating a radical new design, the tools deliver lower machining costs through maximum metal removal in a broad range of materials, including steel, stainless steel, high-temperature alloys and cast iron.

The game-changing tool is setting new performance standards in milling. Last year, the company received an Edison Award for the HARVI I TE end mill, taking gold in the Metal Production subcategory of the award’s Applied Technology category.

Named after the inventor Thomas Edison, the award honors innovations in fields such as new product and service development, marketing, design and innovation.

An Innovative Design

Kennametal engineers designed the HARVI I TE to address four key problems that plague more than 90 percent of all milling applications:

Chip evacuation

Tool deflection

Corner stability

Breakage due to radial cutting forces

The HARVI I TE incorporates an innovative flute design that helps curl and break chips into manageable pieces, while a series of chip gashes within the flute lift those chips up and away from the workpiece.

Both these features promote coolant flow, eliminate chip re-cutting and improve tool life. The twisted end face and unique gashing not only promote chip evacuation but also account for the HARVI I TE’s strong ramping and plunging capabilities.

When it comes to tool deflection, the HARVI I TE’s parabolic core—and its eccentric, faceted relief along the entire flute length—significantly lower tool deflection and friction. This relief also increases edge strength, making the tool a versatile solution. Working alongside the tool’s variable helix angle and asymmetric flutes, it dampens vibration before it can negatively affect machining operations.

An ‘All-Rounder’

The result of these innovations, which are patented and new to the industry, is a tool that’s durable and versatile enough to tackle the lion’s share of milling applications, says Kennametal’s Steve Archambault, regional product manager, Americas.

“The twisted end face, the chip gashes in the flutes and the faceted relief—those three things are the main contributors to why this end mill delivers such outstanding performance in terms of speed and feed capabilities, but also in terms of requiring less spindle power from a machine, which is important for machines that aren’t so powerful; you can comfortably run higher-end applications on smaller machines,” he adds.

The tool is also an all-rounder in terms of the applications it can tackle, including demanding operations such as full slotting up to two times the diameter, ramping, roughing and finishing, and shoulder cuts. The video below shows how the tool’s twisted cutting edge increases corner stability, enabling soft cutting action even at the highest ramping angles.

Higher Feeds and Speeds

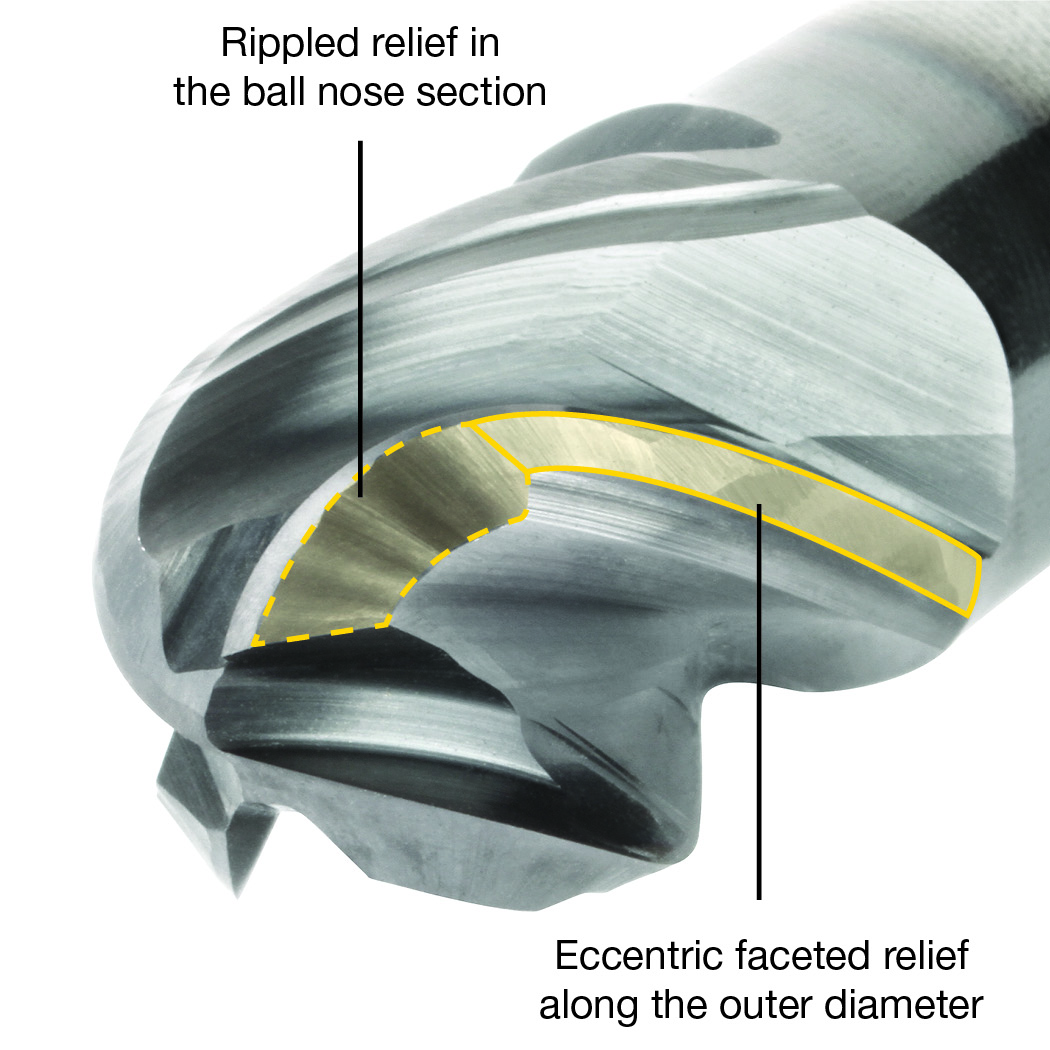

The brand-new ball-nosed version of the HARVI I TE end mill series is just as versatile as the square-end version.

Designed for highly productive 3D roughing and finishing operations, it features a “rippled relief” in the ball nose section that provides improved coolant flow into the cutting zone and disperses heat. The rippled relief allows for higher feeds and speeds as well as increased depth of cuts by advanced vibration damping and lower cutting forces.

The HARVI I TE ball nose end mill just adds to the versatility of this end mill series. Capable of covering many materials and many applications with just one tool, HARVI I TE often eliminates the need for extra tooling and helps to reduce manufacturing costs.

This is a big benefit for the end user, Archambault says. For example, you might need another tool for an entry to create a pocket, and then go deeper with an end mill. This tool can plunge deep into a pocket or eliminate pre-drilling. You can use it with just about any material in any application. It goes beyond the capability of a normal end mill, he says.

What tools have helped you make your shop more productive? Share your thoughts in the comments below.

Related Articles

Inside a Certified Weld Center: Producing Lenox Band Saw Blades at Scale

![Abrasive Selection Guide: Choosing the Right Grinding and Finishing Solutions [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/1PP33ignTLl0VM0awoD294/e585b6ab26bf3bf71e34aa622fcf3437/GettyImages-905155112_Image3-thumb.jpg)

Abrasive Selection Guide: Choosing the Right Grinding and Finishing Solutions [Infographic]

HOW TO Finish the Job with Automation

Combining Machining Operations Into a Single Tool Cuts Machining Costs and Improves Process Control