Video: KOR™ 5 King of Roughing: Rise and Take the Throne

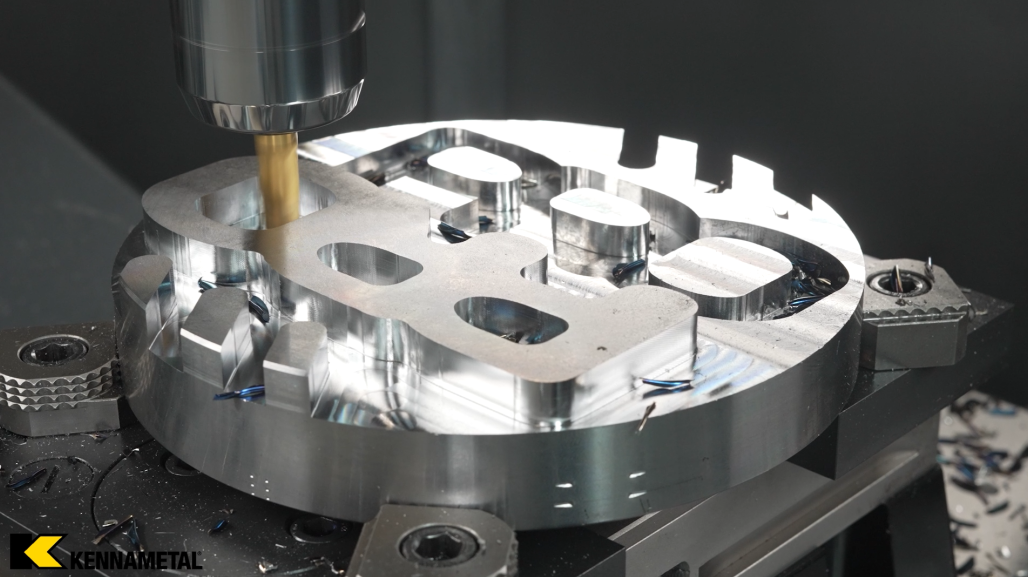

The KOR™ 5 roughing end mill from Kennametal offers high-efficiency metal removal capabilities in aluminum, with features that maximize capabilities of 5-axis machines.

The KOR™ 5 roughing end mill from Kennametal offers high-efficiency metal removal capabilities in aluminum, with features that maximize capabilities of 5-axis machines.

Some of the unique features of the new KOR™ 5 from Kennametal include:

High-efficiency metal removal capabilities in aluminum.

Features that maximize capabilities of 5-axis machines.

Dynamic milling, using CAM tool path generation software.

A proprietary flute form, and chipbreaker enabling 3 x D maximum depth of cut, and perfect chip evacuation.

With the KOR™ 5 5-flute end mill, table feed rates increase up to 66% compared to commonly used 3-flute tools—redefining productivity for aircraft manufacturers and their suppliers.

Watch the short video above to see the KOR™ 5 in action.

Go to MSCDirect.com to view the complete line of the new KOR 5 end mill from Kennametal.

Hey I'm Nick here again at the technology lab at Kennametal in Latrobe, PA. Today I'm here with my buddy Jake again and he's going to be demonstrating some cutting in aluminum with the MaxiMet™ three-flute end mill and the new King of Roughing five-flute end mill also known as the KOR 5.

Let's get to it so let's do some side milling starting without cooling. The KOR 5, unlike most end mills designed for aluminum cutting, has five cutting edges as opposed to the typical two or three. Now let's turn the coolant on. The KOR 5 has a unique patented flute form for better chip formation and allows for improved coolant flow through the flute. It's also equipped with internal coolant technology which helps flush chips away from the cutting zone, improve lubrication and reduce heat.

Without internal coolant, flood coolant does not always provide its full benefits to the end of the cutter. Now we're going to be helical ramping to start a pocket and then continue to open up the pocket using dynamic milling. The KOR 5 is equipped with chip breakers for better chip management, a unique feature for aluminum tools. This helps avoid recutting chips and pockets and other small areas as well as eliminates issues with long chips tangling in the chip conveyer. Thanks so much for checking out the new KOR 5. We'll see you next time.

Kennametal brings together materials science, technical expertise, innovation and superior customer service to help the world fly, drive, power and build. Our tools, materials and wear-resistant solutions enable customers to run longer, cut faster and machine with greater precision across various industries from aerospace and defense, general engineering and transportation, to earthworks and energy. We don’t just make products, we deliver solutions.