VIDEO: KOR™ Series End Mills–Dynamic Milling Vs. Conventional Milling

Kennametal expands its KOR series end mills, designed for dynamic milling using CAM tool path generation software.

Kennametal expands its KOR series end mills, designed for dynamic milling using CAM tool path generation software.

KOR™5DA

Made for high velocity in ALUMINUM, using high agile 5-axis machine centers and applying latest dynamic milling technologies by fully utilizing the CAD/CAM chain.

Additional cutting edges versus the typical 2 and 3 flute tools for aluminum.

Chip breakers added for better chip management, to avoid re-cutting chips in pockets and tight cutting areas and also to help eliminate issues with the chip conveyor.

Patented flute form for better chip room and to allow coolant to flow in the flute better.

Internal coolant to flush chips away from the cutting zone.

KOR™5DS

Made for high velocity with focus on STEEL & STAINLESS, using high agile 5-axis machine centers and applying latest dynamic milling technologies by fully utilizing the CAD/CAM chain.

Chip deformers added for better chip management, to avoid re-cutting chips in pockets and tight cutting areas and also to help eliminate issues with the chip conveyor.

Chip deformer provides excellent surface finish.

Patented flute form for better chip room and maximum tool stability.

Proprietary end face design; highly efficient helical interpolation and overall cutter strength.

Now available in 3xD and 5xD in inch and metric.

KOR™6DT

Made for high velocity with focus on TITANIUM and other ISO-S materials, using high agile 5-axis machine centers and applying latest dynamic milling technologies by fully utilizing the CAD/CAM chain.

Chip splitters added for better chip management, to avoid re-cutting chips in pockets and tight cutting areas and also to help eliminate issues with the chip conveyor.

Eccentric relief for improved edge stability in titanium machining.

Patented flute form for better chip room and maximum tool stability.

Proprietary core design for maximum tool stability.

Utilizes HARVI III aerospace design

Now available in 3xD and 5xD in inch and metric.

Kennametal's KOR series end mills for high-velocity milling applications ensure exceptionally high metal removal rates in aluminum, steel, stainless steels, titanium and other ISO-S materials. They are designed for dynamic milling with low radial engagement and full length-of-cut maximizing capabilities of 5-axis machines, using CAM tool path generation software.

Previously Featured on Kennametal's YouTube channel.

You've already learned about the KOR™5 for aluminum, but we're proud to announce that the KOR family is growing. Kennametal now offers a king of roughing for aluminum, a King of Roughing for steel and stainless steel, and a King of Roughing for titanium as well.

King of Roughing end mills are designed specifically to utilize CAD/CAM tool software taking into account the shape of the workpiece more so than the tool itself. Using dynamic milling techniques, these tools deliver the highest metal removal rates worthy of the throne. Let's take a quick look at the members of the royal family.

The KOR 5DA as you know is a 5-flute end mill with or without through coolant and chip breakers designed for dynamic milling and aluminum. The KOR 5DS is a 5-flute end mill designed for dynamic milling in steel and stainless steel. The KOR 6DT is a 6-flute end mill designed for dynamic milling in titanium.

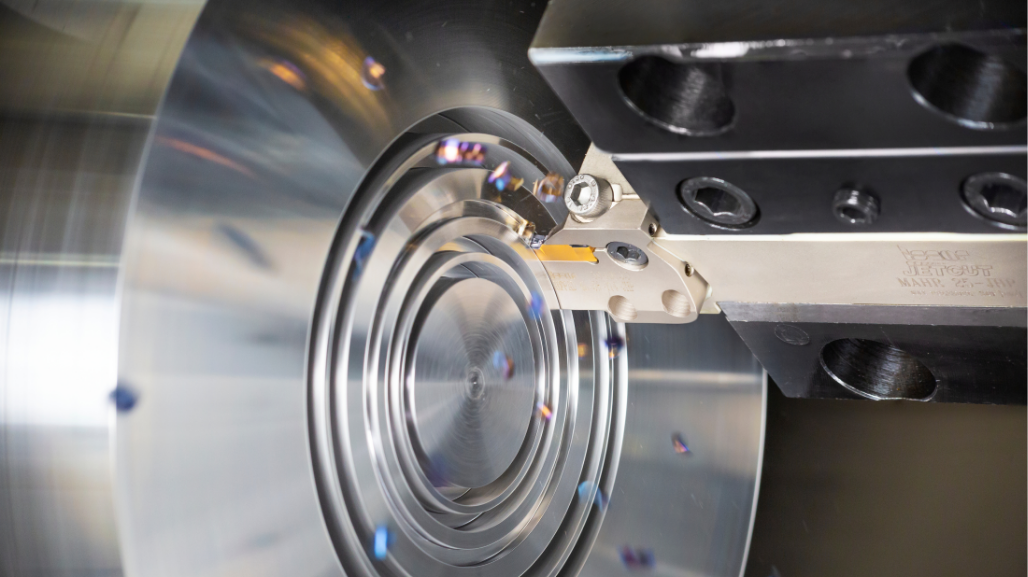

What we're going to do is a comparison between dynamic milling tool design and tool design for conventional milling. Because flood cooling impairs the visibility of these applications, we're going to focus on steel for maximum visibility. We're machining this block of steel dry. We're going to machine the same part twice, once with the HARVI™ II 5-flute end mill using conventional milling and 1xD and 70 radial engagement, and then once more with the KOR 5DS using dynamic milling at 3xD and 15 radial engagement. In conventional milling, end mills need to run at lower axial engagement and higher radial engagement. This requires machining the work piece in multiple steps and also requires the tool to run slower.

See how we had to add a second step here? Now let's move on to dynamic milling. With dynamic milling we can eliminate these extra steps and speed up the process by decreasing the radial engagement and increasing the axial engagement and increasing velocity due to the higher axial engagement. The stability of the tool is also much higher. In this case, we see four active contact points on the KOR 5DS versus the HARVI II with only one active contact point.

With dynamic milling we achieve higher feeds and speeds, lower cutting forces, less vibrations, lower temperatures, lower pressure on the tool, leading to higher productivity and higher tool life.

If conventional milling is your only option, the HARVI II, HARVI III, and MaxiMet™ end mills deliver great productivity on aluminum, steel and stainless steel, and titanium.

Thanks for checking out the KOR product line. If you like this video be sure to give it a thumbs up and subscribe to our channel so you don't miss our upcoming videos.

Kennametal brings together materials science, technical expertise, innovation and superior customer service to help the world fly, drive, power and build. Our tools, materials and wear-resistant solutions enable customers to run longer, cut faster and machine with greater precision across various industries from aerospace and defense, general engineering and transportation, to earthworks and energy. We don’t just make products, we deliver solutions.