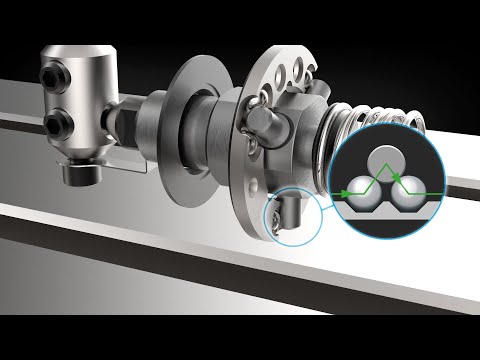

VIDEO: Probing Basics: How a Contact Tool Setting Works

Renishaw's probing systems eliminate costly machine downtime and the scrapping of components associated with manual setting and inspection.

Renishaw's probing systems eliminate costly machine downtime and the scrapping of components associated with manual setting and inspection.

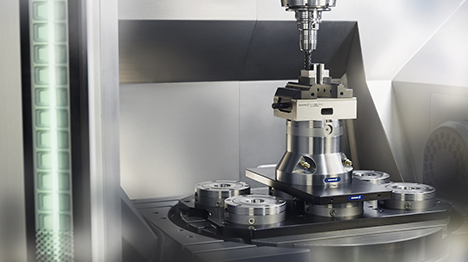

Time is money, and unnecessary time spent manually setting tools and workpiece positions will impact on your manufacturing performance and profitability. Renishaw's probing systems eliminate costly machine downtime and the scrapping of components associated with manual setting and inspection. But, how do their systems work? Here you can see what happens inside their contact tool setters when a tool makes contact with the stylus (captions only, no transcript).

Previously Featured on Renishaw's YouTube channel.

Renishaw is an established world leader in engineering technologies, with a strong history of innovation in product development and manufacturing. Since its formation in 1973, the company has supplied leading-edge products that increase process productivity, improve product quality and deliver cost-effective automation solutions.