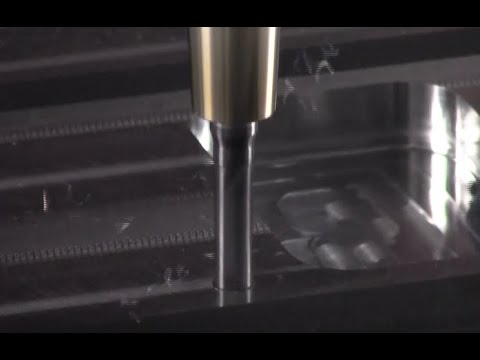

Video: 60sec Troubleshooting–Drilling Built-Up Edge

Did you know there are steps you can take that will prolong your tool’s life even when dealing with softer and gummier materials? In this short troubleshooting video, OSG shows you how to drill built-up edge.⠀⠀⠀⠀⠀⠀ ⠀⠀⠀⠀⠀⠀⠀⠀ ⠀⠀⠀⠀

Watch time: 1:14 minutes

Watch time: 1:14 minutes

Supplier:

OSG

Posted date:

May 27, 2020

Posted date:

May 27, 2020

Looking for full transcript of video? Read now

Did you know there are steps you can take that will prolong your tool’s life even when dealing with softer and gummier materials such as aluminum or magnesium? In this short troubleshooting video, OSG shows you how to drill built up edge.⠀⠀⠀⠀⠀⠀⠀⠀ ⠀⠀⠀⠀⠀⠀⠀⠀ ⠀⠀⠀⠀

Previously Featured on OSG's YouTube channel.

Shop MSCDirect.com to find drilling, threading and milling solutions from OSG.

Video Transcript

Welcome to OSG's 60-second troubleshooting video. Built-up edge is a phenomenon that induces rapid wear when drilling, especially in softer and gummier materials. The work material repeatedly adheres to the cutting edge of the drill then is torn away, resulting in rapid loss of the coating or the tool substrate, significantly reducing tool life. Generally, built-up edge occurs when cutting temperatures are high, resulting in a kind of welding of the work material.

The risk of built-up edge is elevated in low melting temp materials such as aluminum or magnesium. To ensure long tool life when dealing with these gummy materials, proper care must be taken in application setup. First, use a tool that has a cutting edge sufficiently sharp to shear the material while drilling. Next, ensure that the speed and feed settings are reasonable for the material. High-speed, low-feed settings will tend to heat the tool more than moderate speed and feed.

If possible, use coolant while drilling. This both aids in chip evacuation and helps cool the tool, preventing built-up edge. By selecting the proper drill, speed and feed, and coolant type, you can assure a long tool life in your application. Thank you for watching. For more information, visit www.osgtool.com.