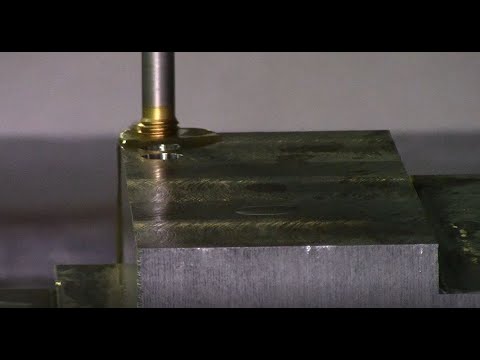

VIDEO: 60sec Troubleshooting–Threading: Tap vs. Thread Mill Cutting Forces

In this short video, OSG discusses the benefits of using a thread mill versus a tap when threading a hole with a low-powered machine.

In this short video, OSG discusses the benefits of using a thread mill versus a tap when threading a hole with a low-powered machine.

In the short video above, OSG discusses the benefits of using a thread mill versus using a tap when threading a hole with a low-powered or small-spindled machine.

Previously Featured on OSG's YouTube channel.

Browse cutting solutions from OSG on MSCDirect.com.

Welcome to OSG's 60-second troubleshooting video. When threading a hole with a low-powered machine, sometimes larger taps, especially over 5/8, can overwhelm and stall a spindle. The forces caused by tapping are very high due to the hole engagement even more so in the case of form tapping as seen in this video. The combination of weak torque machines and large tap engagement can make creating a thread very difficult. To decrease forces on the spindle, you need to reduce the engagement between the tool and the workpiece. A thread mill will accomplish this because the material never engages 360 degrees around the tool as it does with a tap. So, if you're having trouble making a thread using a low-powered or small-spindled machine consider using a thread mill. It will allow for significantly lower cutting forces on your machine that won't overpower your spindle. Thank you for watching. For more information please visit www.osgtool.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.

![Abrasive Selection Guide: Choosing the Right Grinding and Finishing Solutions [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/1PP33ignTLl0VM0awoD294/e585b6ab26bf3bf71e34aa622fcf3437/GettyImages-905155112_Image3-thumb.jpg)