Whether you’re looking at your shop floor processes or the performance of your machines, data analysis helps you identify patterns and predict outcomes. If harnessed correctly, this information can positively affect your productivity and bottom line. Here’s what you need to know about using data to improve manufacturing efficiency.

It’s uncertain when the Fourth Industrial Revolution began, but most manufacturing experts agree it’s here and in full swing. While previous industrial revolutions brought us increased efficiency due to mechanization, electrical power and then electronics, “Industry 4.0” is all about data and digitalization. It’s about artificial intelligence and machine learning, virtual twins, augmented reality, computer simulation, cyber-physical systems and so much more.

A large chunk of Industry 4.0 revolves around—and is in part made possible by—its data-driven counterpart: the Industrial Internet of Things (IIoT). Just as consumers have embraced smartphones, smart cars and smart appliances over the past decade or so, manufacturers have begun using similarly smart technology, including machine tools, robots and software-based systems.

Use Cases for Data Analytics in Manufacturing

All these technologies generate massive amounts of data. Some call it “big data.” Whatever it’s called, it’s what you do with it that counts. Here are some good uses of this data in manufacturing:

Analyzing a factory’s power consumption needs, which helps manufacturers identify inefficient equipment and reduce costs.

Analyzing cutting tool life, which allows machine shops to improve their turning, milling and drilling operations.

Analyzing the downtime on those same machine tools offers unprecedented views into the root causes of low OEE (overall equipment effectiveness).

The result of all this analytical effort is additional machine uptime, more predictable processes, improved part quality and less waste. Most importantly, big data and the IIoT are the great equalizers between countries with low manufacturing costs and everyone else on the planet.

How to Start Improving Efficiency with Data and Technology

Getting into this world is easier than you might think. Yes, each of the five technologies described below might require some investment—in time, capital or both—but the ROI in most such implementations is usually quite fast. And if you have a relatively new CNC machine tool and Ethernet cable, the chances are excellent that you can begin gathering data almost immediately.

Here are five ways you can use technology and data to improve operational efficiency:

1: Going Paperless

Data flows in both directions in a digital manufacturing company. If your shop still relies on paper job travelers, tool lists, and setup sheets, it’s time to take them electronic. That’s according to Ryan Zimmermann, director of business development at Visual Knowledge Share Ltd., a fabricating shop turned software developer. Zimmermann notes that digital work instructions promote standardization, help to eliminate mistakes, and significantly streamline operations. It achieves all this via revision-controlled electronic documentation containing images, video and text that can be streamed anywhere on the shop floor.

“We are eliminating the paper trail,” he says. “We are eliminating the binders of paper everywhere, and we’re eliminating all the problems experienced by shops that rely on tribal knowledge. What’s more, because digital work instructions prompt for operator feedback, they ensure compliance while providing higher levels of traceability for human-driven activities.”

Check out Better MRO’s career guides and trends

2: Sharing Insights

Tribal knowledge is potentially a major problem for any enterprise. Unwritten information that is not commonly known by others within a company means important knowledge is not passed on to younger workers.

Someone who can speak at length about the hazards of tribal knowledge is Jeff Rizzie, Sandvik Coromant’s director of digital machining.

“A good machinist can put their hand on a machine or listen to the spindle and know immediately whether there’s a problem,” he said. “But what happens when that person leaves the company?” The best way to eliminate this risk is by gathering manufacturing data from CNC machine tools, Rizzie said, and then analyzing it for productivity-killing variables in the manufacturing process. As indicated earlier, newer equipment already offers this capability, provided the shop is networked and you have somewhere to store said data. Sandvik Coromant offers such a place: it’s called Machining Insights, and like many such systems it provides a host of dashboards and reporting capabilities that make process analysis and improvement easy.

Read more: Tackling the Manufacturing Skills Gap: 5 Skills Your Company Will Need Soon

3: Get Connected

Don’t have one of those newer machine tools? That’s OK, because there are plenty of aftermarket adapters available for legacy equipment that make CNC machinery at least somewhat talkative. That said, it might be time for an upgrade.

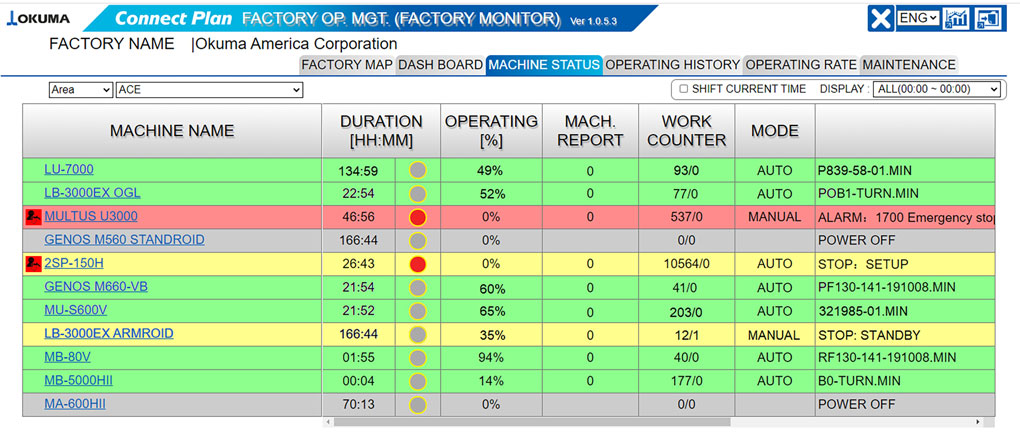

Okuma America product specialist Brad Klippstein ticks off numerous digital machining features available on the company’s newer OSP-series controls, including tool life management, collision avoidance, virtual monitoring (3DVM) and perhaps most importantly to anyone looking to gather machine data, the MTConnect communications protocol.

“We’ve also introduced a new product called Connect Plan,” he says. “It allows you to connect multiple vintages and brands of machine tools through our interface, and it acts as a central repository for collecting information and displaying it in a man-readable format on an integrated dashboard viewer.”

Read more: Industry 4.0’s Smart Factory Is All About That Data

4: Getting Your Data in Real Time

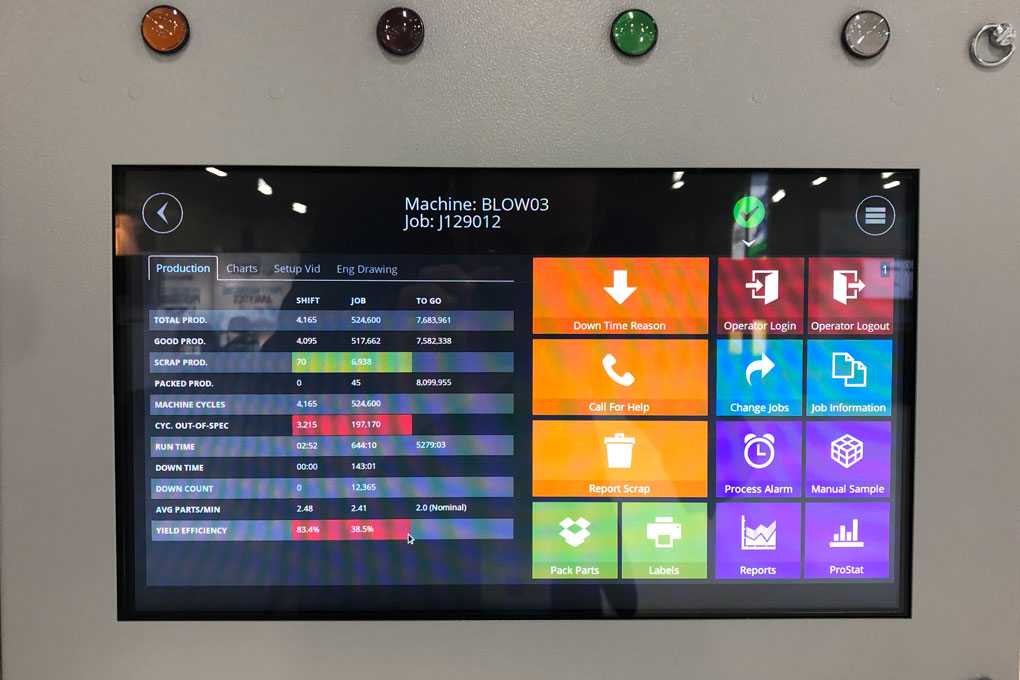

Take the digitization concept a bit further and you’re edging into MES (manufacturing execution system) territory. Andrew Robling, principal product manager at Epicor Software Corp., says MES allows manufacturers to collect data directly from sensor-equipped machine tools and other equipment. This includes OEE information, job quantities, quality data and process-related information like oil pressure and spindle temperature. Such data can then be displayed in various forms—real-time shop floor display boards among them—or used to alert people that there’s a problem. Yet Robling noted that MES does much more than data collection and analysis. It provides a comprehensive suite of scheduling, monitoring and maintenance management capabilities that can serve as the heart of any digital manufacturing initiative.

“One customer I worked with recently said they’d seen a 70 percent increase in overall productivity,” he notes. “Another enjoyed a 13 percent cost reduction on a key product line, while still another cut their cost of quality by $600,000 annually after implementing a MES solution.”

5: Collecting Quality

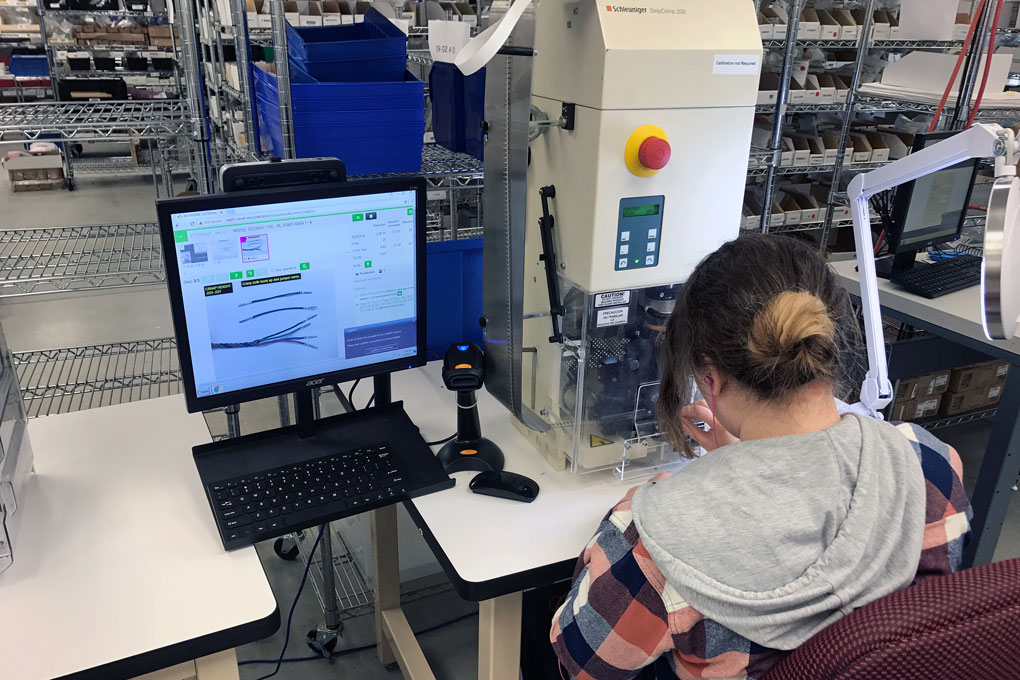

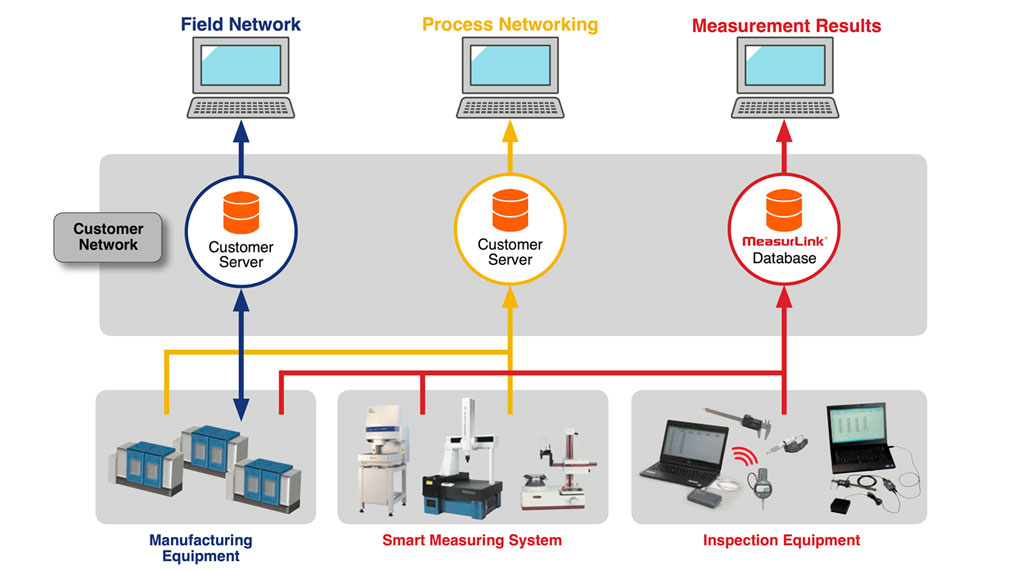

A strategic distribution sales specialist at Mitutoyo America, Patrick Sullivan suggests that one of the easiest ways to reduce quality costs and improve data accuracy is through the automated collection of shop floor measurement information. This can be achieved via a low-power wireless device like the company’s Zigbee-based U-Wave system or a more conventional, wired approach.

In either case, measurement data from micrometers, digital indicators and any other communication-capable device (which is most of them these days) can be sent to an external software system such as Mitutoyo’s MeasurLink for analysis. “The uses for this data extend well beyond metrology,” he notes. “It provides visibility to manufacturing trends that might otherwise go undetected. The result is better process control, reduced machine downtime and so on. And because it’s easy to archive this information, manufacturers can compare past results to what’s going on right now, which gives them better decision-making capabilities.”

Read more: Remote Metrology: Here’s How to Collect Critical Manufacturing Data

Of course, these are just a few of the providers and products available to shops implementing a digital, data-based manufacturing strategy. All serve to make machining and fabricating processes more efficient, predictable and cost-effective.

Because they drastically increase visibility, there’s no more guessing or detective work when something goes awry on the production floor. Best of all, they eliminate reliance on tribal knowledge. Whether it’s paperless manufacturing, remote process monitoring, smarter machine tools and micrometers or a companywide manufacturing execution system, it’s time to take your shop in a digital direction.