Case Study: Bring Your A-Game with the OSG A Brand AT-1 Thread Mill

An oil industry product manufacturer looking to thread mill a link lube assembly turned to OSG's AT-1 to reduce cycle time and increase productivity.

An oil industry product manufacturer looking to thread mill a link lube assembly turned to OSG's AT-1 to reduce cycle time and increase productivity.

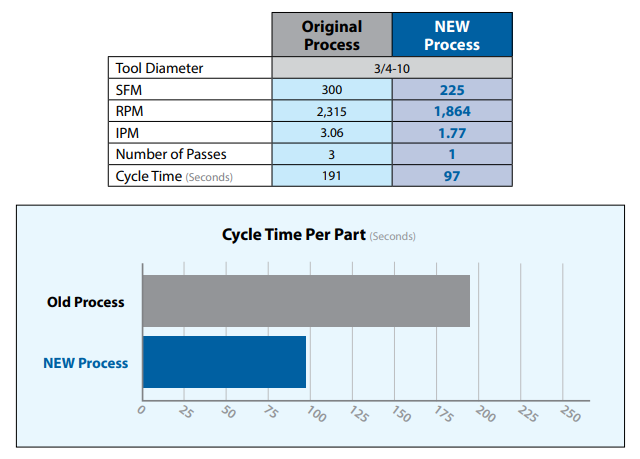

OSG was approached for this opportunity by a customer who was using a conventional full length-of-cut thread mill. Due to the long thread, the customer was experiencing longer than desired cycle times and deflection requiring multiple passes to achieve a quality thread. OSG proposed the A Brand AT-1 thread mill to take on the opportunity. The AT-1 is designed for single-pass thread milling up to 45HRC with its patented left hand helix geometry.

OSG was able to utilize one-pass thread milling with the A Brand AT-1 utilizing a thread mill feed rate compensation.

Number of passes was reduced from 3 to 1

Part production went from 80 to 200 per tool.

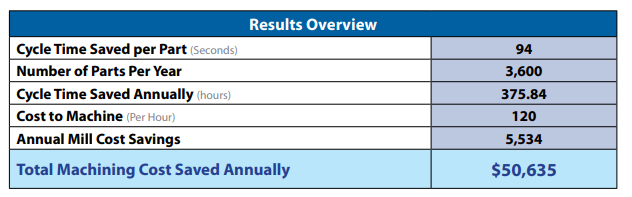

Cycle time was reduced by 94 seconds per part (191sec to 97sec)

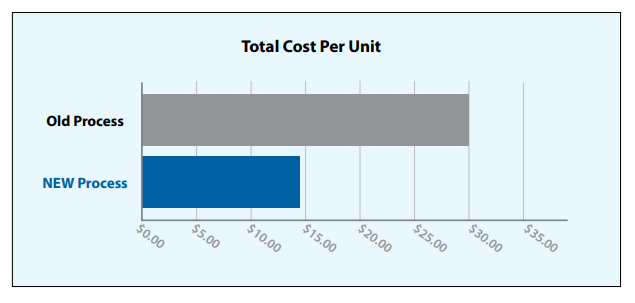

_A total savings of $50,635_

Annual thread mill usage went from 45 to 18 with the OSG AT-1! This alone saves $5,534.28 for a total savings of $50,635!

Previously Featured on OSG Tools' website. Download a PDF of the Case Study here. Browse MSCDirect.com to see the A Brand AT-1 thread mill.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.