KYOCERA SGS Precision Tools (KSPT) has worked closely with a distribution partner and this particular end user in recent years. Many cost-saving achievements have been realized, with this example being the most recent and strongest to date. The end user approached KSPT and their distribution partner with an intriguing challenge. How can production efficiency be improved without adding CNC machining equipment? Building on application engineering support from the KSPT Global Innovation Center, field sales professionals from their supplier and KSPT were able to save the end user more than $400,000 annually through process improvement.

GOALS

Needing to produce jet engine components used in clamping applications in the hot zone of an engine. The end user’s goal was to achieve cost savings by increasing material removal rate and reducing cycle time without purchasing additional CNC machining equipment.

STRATEGY

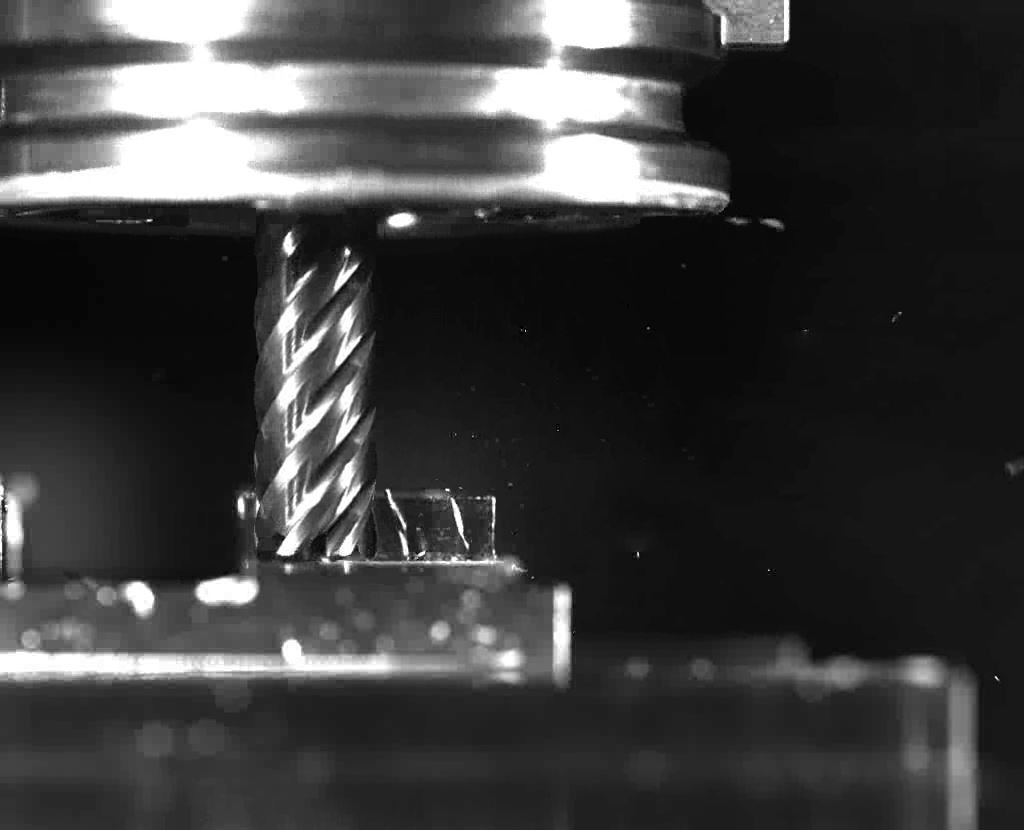

Given the rapidly increasing cost of carbide in the market, extending the life of cutting tools becomes extremely important. While trochoidal milling is not a new technique, it is not nearly as widely used as it deserves to be. When comparing the data in conventional milling techniques to those of trochoidal milling, the benefits become very clear. Applying the KSPT Series 51 T-Carb® allowed for employment of a high-speed chip thinning trochoidal milling approach on the part. This new approach involved milling one pass at .190” axial depth with higher speed and feed rates. The previous conventional method was to take 19 passes at .01” axial depth.

RESULTS

The new process utilizing the Series 51 T-Carb® increased material removal rates by over 90% and cycle time by 134 minutes or 58%. The production efficiency gained freed up 4,540 hours of machining capacity for the end user. The same number of end mills was used to complete the operation at the increased material removal rates. The lower cost of the smaller tool compared to the tooling cost in the previous process allowed the end user to achieve an additional savings of $24,388 annually. This, coupled with the annual machining cost savings, allowed for a total savings of $415,282.

SOLUTION

Utilizing the trochoidal milling technique and its accompanying efficiencies, KSPT and their distribution partner combined their efforts to achieve the challenging goal for the end user. Not to mention, saving them from potentially incurring additional cost of a new Haas VF2 machine.

To review the complete Case Study, click here.