Case Study: Operate Beyond the Limit with the OSG HY-PRO® CARB VGM End Mill

OSG recommended the VGM5 end mill to an oil and gas manufacturer looking to improve cycle time and tool life of their operation.

OSG recommended the VGM5 end mill to an oil and gas manufacturer looking to improve cycle time and tool life of their operation.

An oil & gas manufacturer utilizing an HEM toolpath using a 5 flute end mill was looking to improve cycle time and tool life of their operation.

To provide a high-performance end mill that would deliver a reduction in cost and cycle time while increasing tool life.

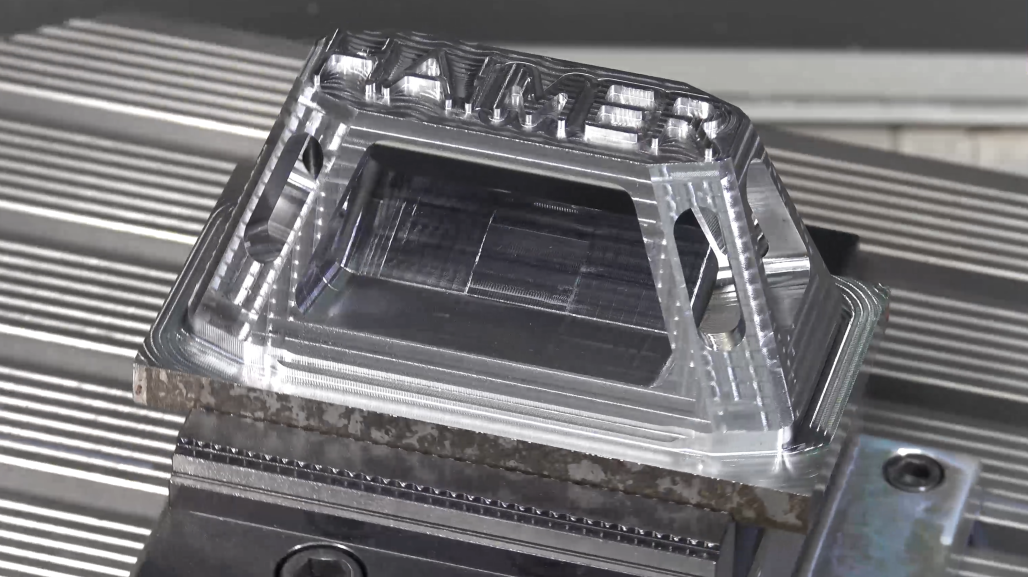

Based on past success in high-efficiency milling of low carbon steels, OSG decided to recommend the VGM5. The VGM tool is an end mill series specifically designed for HEM processing that is competitively priced. With OSG’s expertise of end mill design coupled with their multi-layer EXO coating to provide wear and heat resistance over the conventional TiAlN coating, the VGM5 tool had a significant advantage over the incumbent end mill.

The following results were observed from testing the HY-PRO® CARB VGM5. OSG was able to provide the customer with a more cost-efficient tool and an increase in both productivity and tool life.

• SFM was increased from 280 SFM to 450 SFM. • Cycle time was reduced from 2.55 min to roughly 1.8 min per part. • Number of parts per tool was increased from 9 to 12.

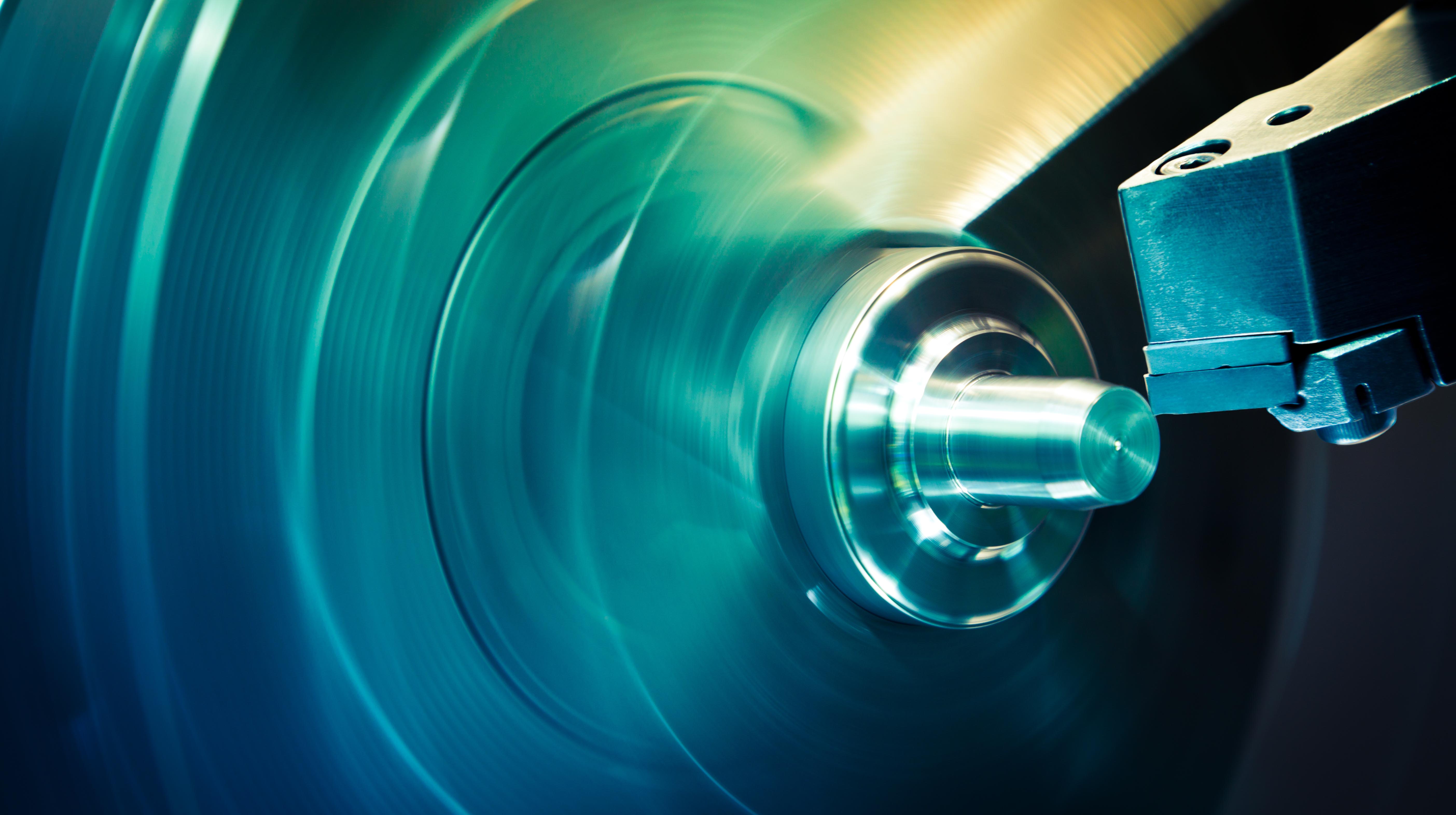

The customer was able to save 1.5 hours of machine time per year. They were also able to improve tool life by 3 parts/tool. Most importantly, the customer achieved their desired goals while saving roughly $870.00.

Previously Featured on OSG's website. Download a PDF of the Case Study here. To learn more about OSG’s HY-PRO® CARB VGM end mills, visit MSCDirect.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.