Looking for full transcript of video? Read now

In this episode of MSC Industrial Supply’s How To series, host Jacob Sanchez heads to Lenox to learn how to minimize downtime in your shop with smarter bandsaw maintenance and a proactive approach to equipment care.

Every minute of downtime costs a shop in productivity, deadlines, and customer trust, and often, it all starts at the bandsaw. Together with Cameron Guthrie, Product Specialist at Lenox, Jacob uncovers the most common causes of machine downtime and explores how Lenox’s 13-Point Bandsaw Inspection and Lenox Plus Services help shops stay ahead of breakdowns.

From checking band wheels, blade guides, and blade tension, to ensuring proper coolant flow, chip removal, and drive system alignment, Lenox’s preventive maintenance process covers every detail that affects cutting performance and blade life. Cameron demonstrates how heat and vibration are a blade’s biggest enemies—and how addressing these through regular maintenance can dramatically improve uptime and consistency.

With Lenox’s new Plus Services, OEM-trained specialists can take maintenance completely off your team’s plate by handling inspections, reports, and even part replacements on a scheduled basis. The result is a smarter, more cost-effective way to manage your saws and protect your shop’s productivity. By partnering with Lenox and shifting from a reactive to a proactive maintenance mindset, manufacturers can keep their equipment running longer, reduce repair costs, and deliver better quality parts faster.

Watch now to learn how to keep your bandsaw, and your entire operation, running at peak performance in this episode of How To from MSC Industrial Supply.

For even more insights and expertise, check out MSC's Knowledge Center.

“How To” is a video content series from MSC Industrial Supply developed to serve as a resource for all those who work in, support, and have a passion for the metalworking sector of the manufacturing industry. Through How To, you’ll gain hands-on, practical advice from industry experts currently working in the field. At MSC, we are dedicated to providing real-world, practical advice to improve your day-to-day operations.

For more How To videos, check out our MSC How To playlist and subscribe to our YouTube channel.

And check out our other show, Tooling Up, on the MSC Tooling Up playlist.

Video Transcript

JACOB SANCHEZ: Silence. It puts machine shops all around the world on edge. Because if your spindles aren't turning, that clock starts ticking. You're losing money. You're missing deadlines. You're putting your customer's trust on the line. And if you have a bandsaw in your machine shop, you know this is the first step in the machining process. And if this thing isn't running, you're not shipping parts.

But what can we do, other than just sit around waiting for something to break? Scramble to go fix it. What is a way? What's a smarter, better way to keep our equipment up and running? That's what I'm here to figure out. I'm here at a machine shop where we're going to be hitting the bandsaw. We're going to be tackling these issues and really rethinking preventative maintenance on our equipment.

You and I, we're going to be learning how to minimize downtime in your shop.

Cameron, good to have you here. I wish it were under better circumstances because I got lines down at my machine shop. Parts aren't shipping, machines aren't running because my bandsaw is down. What are some reasons you've seen this? Like in real life?

CAMERON GUTHRIE: Yeah, sure. Jacob, there's always a few key things. One could be that the shop’s too busy to shut their saw down and not keeping up with the routine maintenance, and they could be facing labor shortages and not using trained operators. Or they may no longer have a dedicated maintenance person on staff.

JACOB SANCHEZ: All of that kind of sums up to me just to cost. Cost this way, cost that way. What's the way that the Lenox team, though, can help besides providing just an awesome blade?

CAMERON GUTHRIE: Yeah, we've always supported our customers with our legacy 13-point check. But now we've evolved. We're listening to what our customers' needs are. Our sawing solutions group now has the ability to implement what we're calling our Plus services. This is a team of OEM-trained specialists that will go into your facility and they'll do all the work for you. We're finding that it's a more cost-effective way of doing the maintenance versus keeping full-time maintenance people on staff.

JACOB SANCHEZ: And besides that, I feel like it's also you're taking, quite honestly, the burden of knowledge away from the shop that they would have to distribute to their employees who are already busy doing so much of the work. And you, as the product specialists and the experts, are taking that upon yourself to get the job done.

CAMERON GUTHRIE: Yeah, we always see ourselves as a subject matter expert in front of the bandsaw, whether it's training the operators, teaching them the best feeds and speeds, best sawing practices, and then also on the actual working of the bandsaw, making sure it's working at its best, optimal performance.

JACOB SANCHEZ: Today, we're going to be seeing that 13-point check, though. Correct?

CAMERON GUTHRIE: Yeah. Let's go out there and take a look at what the application specialist looks for.

JACOB SANCHEZ: Yeah. I’m down.

CAMERON GUTHRIE: Jacob, let's take a look at some of those 13 points.

JACOB SANCHEZ: This is where it's happening.

CAMERON GUTHRIE: This is it.

JACOB SANCHEZ: All right. So we're going to get after that 13-point inspection we were talking about in the room. We're going to get after how to get a bandsaw. Preventive maintenance up and running. Stay running. This will be sweet.

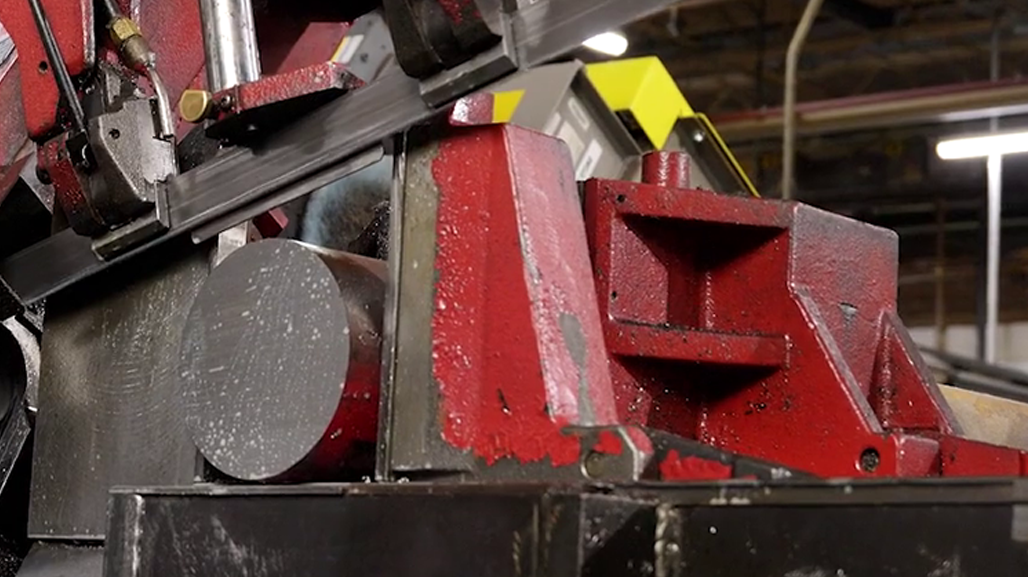

CAMERON GUTHRIE: Typically, heat and vibration are the two worst enemies of a blade. So we would generally start with the band wheels. Okay. So we're going to be taking a look at the wheel bearings. Make sure they're nice and tight. We're going to be looking at the surface of the band. We'll make sure it's wearing evenly.

Cool. And then we're going to be making sure that the blade is tracking properly on that wheel itself. And then obviously, with heat being a major component of sawing, you want to make sure your fluid is set up properly and make sure that it's mixed at the right ratio, flowing through the coolant valves and into the workpiece.

Another big component on a saw is going to be the blade guides. So these are little carbide pads here. You want to make sure that those are wearing evenly. You want to make sure there's no corners chipped. Blade tension is very important. So we're going to take our tension meter. We're going to check the stretch of the blade in between the guides.

If that's set properly, it's going to get us a nice square cut. We also have the blade guide alignment. So we'll drop the head of the saw, but a square up against that. We want to make sure the blade is positioned 90 degrees to the bed of the saw. The blade tracking system I mentioned earlier. But we want to make sure that that blade is positioned properly on the band wheel.

The drive system is obviously important. The motor, the transmission, make sure that they're operating properly. The chip removal system is very important and oftentimes overlooked. That chip brush sometimes is removed. It's oftentimes dropped out of the way and not positioned properly back to the blade itself. Band speed verification. We're going to take our tachometer. We're going to take it, we're going to put it up against the blade while it's running, and we're going to compare it to our blade verification meter over there to make sure that they agree with one another.

Obviously, the control panel components, the feed system is very important. So we got a feed pressure and a feed rate control valve. We want to make sure that we're making those adjustments, the saw reacts accordingly. Oh, also very important would be your vises. Make sure they're clamping the parts tightly. Obviously, with vibration that's the enemy of a blade. Anytime a part moves you're generally going to lose blade life.

JACOB SANCHEZ: Now that is a process and a very well done one at that. Brother, usually what would happen next is you drop off a report on my desk and that's that. With this new Plus program with Lenox, what can happen now?

CAMERON GUTHRIE: This is where the partnership really began. So with the 13-point plus and the 20-point plus programs, we're not just leaving you with that service report. Our team of specialists will come in and replace those worn guides. They'll change your hydraulic fluid. They’ll install those necessary replacement parts right here, right now. We can schedule those quarterly visits so we can be your dedicated maintenance team. And really, you don't have to find the time or the labor. We can handle all of that.

JACOB SANCHEZ: I think that's a big thing about keeping my facility and my shop up and running. I appreciate everything you did today, everything you showed me.

After today, I think we've realized to reduce downtime, we're going to really need to shift our mindset. We're going to need to go from being reactive to proactive. We're going to need to analyze and identify situations before they become real problems. Because by doing that, we can stay one step ahead. And if we can create a network of partners and trade relationships with experts like the team here at Lenox, we won't be just maintaining some piece of equipment. We'll be protecting our entire operation. And now, after all that, you and I, we know how to minimize downtime in your shop.

Narrator: For more metalworking tips and industry best practices, stay tuned for the next How To episode and subscribe to the MSC Industrial Supply YouTube channel, a source of original manufacturing content Built To Make You Better.