Video Transcript

BRENDT HOLDEN: When you use a modular system of any kind, basically, you're saving on carbide cost because all you're doing is replacing the head. So if you have a deep-breach application or something that would normally require a very long piece of carbide, you can save money there. And in addition to that, you do get better tool life with all the Haimer cutting tool products. Basically, because of the optimized chip evacuation.

Narrator: This episode of Tooling Up is brought to you by Haimer. With Haimer, quality wins. If you're looking for real-world insights, tips from leading industry experts, the latest trends in products and technology, you've come to the right place. From MSC Industrial Supply, this is Tooling Up.

TONI NEARY: Hi everyone, and welcome to Tooling Up. I'm your host, Toni Neary, and I'm so glad that you've joined us today. Before we jump in with our guest, let's take a minute to click those like and subscribe buttons so you never miss an episode from MSC and our industry partners. All right. Did everybody click? I'm thrilled to welcome back our guest for today, Brendt Holden, the President and CEO of Haimer USA. Brendt, thank you so much for joining us again.

BRENDT HOLDEN: It's a pleasure. Thank you for having me, Toni.

TONI NEARY: Some of you may remember our Season 3 discussion with Brendt, where we were primarily talking about ShrinkFit, a major part of Haimer's legacy and expertise. But today we're expanding that story because something a lot of people don't realize is that Haimer also manufactures cutting tools that are designed to work as part of a complete and fully optimized tooling assembly.

So let's jump in. Haimer is known worldwide for precision tool holders, and you are compatible with every major cutting tool on the market. So why make the move into cutting tool manufacturing?

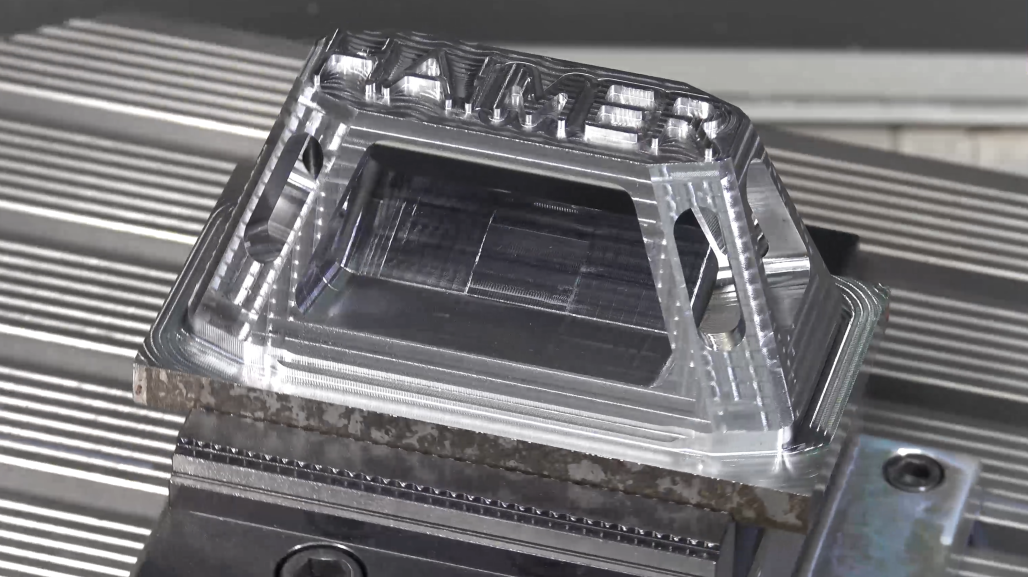

BRENDT HOLDEN: Haimer always looks forward to the future. And our engineering team and Mr. Haimer, we're noticing a lot more people move to a modular cutting tool system. And in that case, there wouldn't be as much need for round shank tool holders. So, looking to the future, we thought it's important that we became involved in that. And at Haimer, we make 4000 tool holders a day, and we actually use our product and produce our products.

So we figured we could actually do this R&D in-house and figure out what is the most rigid system that's possible. And the ultimate goal is to increase metal removal rate and get your parts machined faster. So that put us to the drawing board. We purchased a whole bunch of cutting tool grinding machines and started to produce the modular system, along with some solid carbide end mills, in our production plant in Germany.

TONI NEARY: Brendt, I think it's important. Obviously, higher metal removal rates are great because we're looking at more production and shorter time spans. But I also think we have to talk about the accuracy and the longer tool life with the new solution as well. Tell us a little bit more about that.

BRENDT HOLDEN: Well, you're exactly right, Toni. In fact, with the Haimer solution, we can provide better run on accuracy. Better tool life. And actually, because one of the main reasons we can do that is that we're actually looking at the full assembly of the tool there and the cutting tool, which is pretty unique. And that's based on our tool holder experience for all these many years.

TONI NEARY: So let's keep building on that, Brendt, because modular isn't new, but Duo-Lock performs differently. So tell us a little bit about what really sets it apart.

BRENDT HOLDEN: You know, as we looked into what was available on the market when it came to modular systems, we noticed that usually the thread connection was the weak point. So, back to that six years of R&D. We basically looked at what can we do to create the most rigid interface. That was the key component moving forward. So we have a double, thread connection and a cone, and also a pilot that helps center the modular cutting tool in the extension or the holder to really provide a rigid interface.

And with that rigid interface, we accomplish what we thought was one of the major challenges is being able to machine with a modular cutting tool system, similar to how you would machine with a solid carbide end mill. And that's really key. And then when you actually have the setup correctly and rigid, you get a lot of different advantages, such as the Z-axis dimension, being very consistent when you change out the heads of the cutting tools.

Also, you can put them in live tooling or driven tools for late applications, very simply and easily, in a quick manner. In addition, you can take those heavy cuts that we talked about. So it allows you to increase metal removal rate with an accurate solid system. And that's what we found to be the key to making the Duo-Lock successful.

TONI NEARY: And with the Duo-Lock you get better accuracy, better part quality, and more flexibility. And you aren't locked into one supplier. And I think that's compelling. And I think that's a big deal for customers.

BRENDT HOLDEN: And don't forget, when you use a modular system of any kind, basically you're saving on carbide cost because all you're doing is replacing the head. So if you have a deep reach application or something that would normally require a very long piece of carbide, you can save money there. And in addition to that, you do get better tool life with all the Haimer cutting tool products, basically because of the optimized chip evacuation.

And that makes sure that you do not double cut chips. So that's going to make the cutting tool last longer, too.

TONI NEARY: And I love the fact that we've talked about the modular base. So the next piece of the puzzle is the cutting tools themselves. And Haimer has two that play beautifully together. The Haimer Mill and the Panther Mill. Walk us through what differentiates them and why they're so complementary.

BRENDT HOLDEN: The next step after we developed the Duo-Lock was to realize that, hey, we have a lot of machining done in-house, so why don't we make some solid carbide end mills for our own production? So we created the Haimer Mill and the Panther Mill. Both are very good universal end mills for machining all kinds of different materials, such as steel, stainless steel, aluminum, cast iron, all the different things that we machine in-house.

And they're basically set up for very aggressive metal removal rates with high efficiency machining techniques. So basically, the Haimer Mill itself can drill and can ramp at a very aggressive 45 degree angle, whereas the Panther Mill is more for profile milling and also some finish work, but together it works very good. And the reason that it works so good is basically it can extend to life with our PVD coating, which can extend to life up to 30 to 40%.

And our edge prep. That's really key as far as the consistency of the product.

TONI NEARY: Now let's shift from the cutter to the holder, because Haimer took ShrinkFit to an entirely new level with the Hybrid Chuck. And Brendt, this one's pretty groundbreaking. So what makes the Hybrid Chuck so different than anything else out there?

BRENDT HOLDEN: The Hybrid Chuck is the first ever active vibration dampening, ShrinkFit chuck on the market, and how we accomplish that is with the design. Again, this was, at least five years of R&D patented idea from Haimer where we actually have an inner sleeve that has a gap between the outer cone of the ShrinkFit chuck and the actual body of the ShrinkFit chuck.

And that little air gap allows for vibration and place to go if there is vibration still in the cut. So this absolutely dampens the vibration in the cutting when you're using high-efficiency machining techniques. And we found amazing success in our production facility, even with this. And it does require a bit of a mind change, as far as how you approach the part.

And the example I have is we've been making, basically, the motor housing for our bouncing machine since 1996. And with that operation, we were using basically a 50 millimeter insertable 4 flute cutter, and we switched to a 12 millimeter Haimer mill with the hybrid chuck. Actually, it was a Panther Mill with the hybrid chuck. And in that case, we were able to reduce the cutting time 57% when making this part that we make all day long.

I've been making it for years, so a 57% reduction really helped our production. And that's the kind of thing the hybrid chuck can do for actually the customers out there in the field as well.

TONI NEARY: That is a huge percentage. And the fact that you achieved it with a smaller 12 millimeter tool really shows what the full assembly can do. Same material, smaller tool, better finish. And so for shops watching this and thinking I want those results, I want 57% reduction, let's talk about what it looks like to adopt the full hammer assembly.

I mean, is that a big lift?

BRENDT HOLDEN: It's not necessarily a big lift at all. Especially if you already have a ShrinkFit machine and you're using ShrinkFit tooling. It's just more of a different mindset. You have to look very closely at your CAM system. You have to look closely at your high-efficiency machining techniques in your programming as it relates to the CAM.

So basically it's utilizing modern technology that's available on the market in order to create the benefit in the machining process. And that's something the MSC Metalworking Specialists and the Haimer Cutting Tool specialists can really work with you on.

TONI NEARY: Brendt, thank you so much for being here with us today.

BRENDT HOLDEN: You're welcome. Toni, it's always a pleasure.

TONI NEARY: It was so great hanging out with Brendt today. And to learn more about Haimer’s full tooling assembly solutions, connect with your MSC Metalworking Specialist or go to www.mscdirect.com/resources/haimer. And don't forget to subscribe to our channel so you never miss an episode. Thanks so much, and we'll see you next time on Tooling Up.

Narrator: Want more insights and ideas to improve the efficiency and productivity of your operations? Check out the Tooling Up video playlist to hear tips that can take your company to the next level, and subscribe to our channel so you won't miss out.