Case Study: OSG A Brand AE-TL-N

An OSG customer was machining Aluminum alloy wheels and looking to reduce their manufacturing cost and increase tool performance.

An OSG customer was machining Aluminum alloy wheels and looking to reduce their manufacturing cost and increase tool performance.

An OSG customer was machining aluminum alloy wheels and looking to reduce their manufacturing cost and increase tool performance.

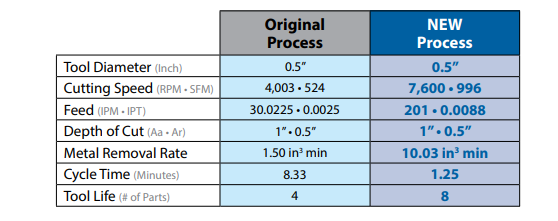

After the initial meeting with the customer, OSG suggested testing the AE-TL-N. OSG had previously seen success in similar applications where other customers were looking to increase Material Removal Rates (MRR) while maintaining or increasing tool life and productivity. One big feature of the AE-TL-N that stood apart from the competitor tool was the DLC coating. This coating is much more wear resistant than the current TiAlN coating and allowed for more aggressive parameters without affecting tool life.

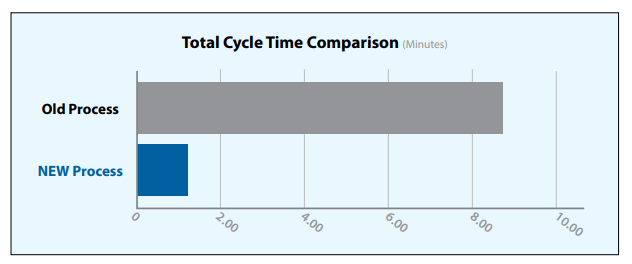

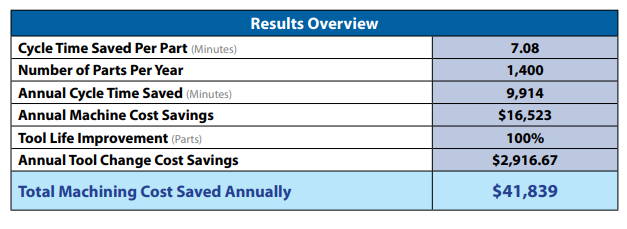

The following results were observed from testing the AE-TL-N end mill. OSG’s AE-TL-N was able to machine double the amount of parts as the competitor tool at a much higher feed rate. This led to a cycle time reduction of 7 minutes per part.

• SFM was increased from 524 SFM to 997 SFM • Tool Cost was reduced by 46% • Number of parts was increased from 4 to 8

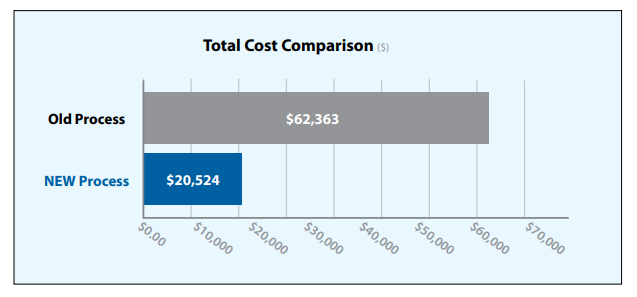

The customer was able to achieve their goal of reducing overall manufacturing costs. The lower tool cost of the AE-TL-N, paired with the higher running parameters greatly reduced the annual tool cost. Tool life of the AE-TL-N was also double that of the competitor tool. All these factors led to a cost savings of nearly $42,000 per year.

Previously Featured on OSG Tools' website. Download a PDF of the Case Study here.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.

![Abrasive Selection Guide: Choosing the Right Grinding and Finishing Solutions [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/1PP33ignTLl0VM0awoD294/e585b6ab26bf3bf71e34aa622fcf3437/GettyImages-905155112_Image3-thumb.jpg)