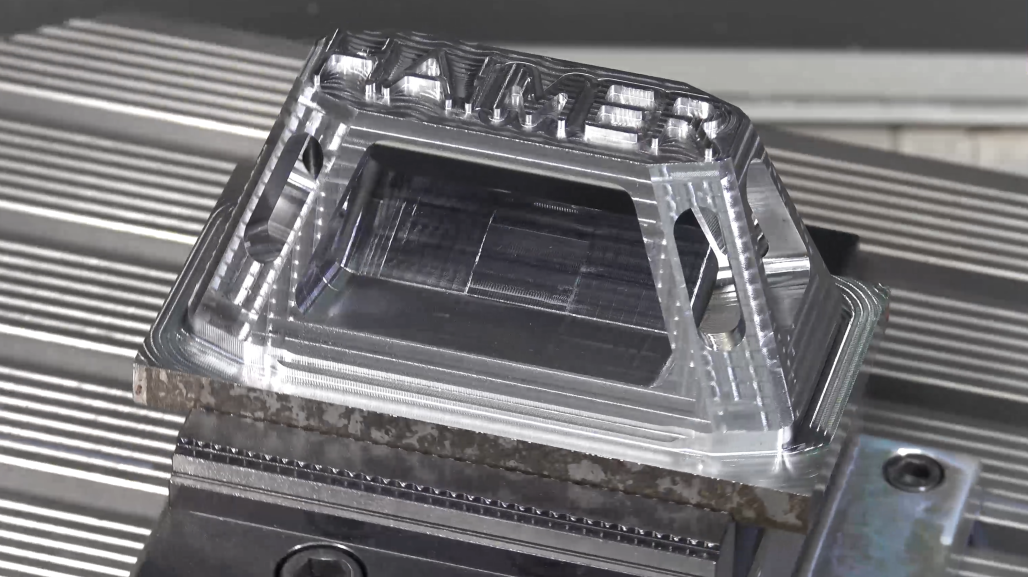

Case Study: Teaming with Fort Walton Machining in Aerospace

Castrol and Fort Walton teamed up to run trials and receive the OEM approval for Hysol SL 45 XBB.

Castrol and Fort Walton teamed up to run trials and receive the OEM approval for Hysol SL 45 XBB.

To ensure safety and quality of parts, a major US aerospace manufacturer has stringent requirements to approve coolants for manufacturing parts that go into their airplanes. Gaining approval takes the sponsorship of a Tier 1 part supplier to prove out the coolant's technology and performance.

So Castrol and Fort Walton teamed up to run trials and receive the OEM approval for Hysol SL 45 XBB. The product met the tough standards and received OEM approval.

A next-generation metalworking fluid created specifically for the aerospace industry and approved by major manufacturers. This soluble cutting fluid is designed for grinding, milling, turning, drilling, reaming, tapping and broaching a range of aluminum and titanium alloys, and is suitable for machining ferrous alloys.

Watch now: Fort Walton Machining Case Study

Upon implementing Hysol SL 45 XBB, this customer observed a 60-80% increase in equipment life and less emulsification, all without using chloride and biocide.

Previously Featured on Castrol's Testimonials and Success Stories.

Castrol has all of the industrial lubricants, fluids and industry expertise you need to help reduce your Total Cost of Ownership by increasing productivity, reliability and sustainability. Castrol has been collaborating with industrial businesses like yours since 1899. Using that experience, Castrol continues to develop new solutions to challenges that businesses face across all sectors of industrial manufacturing.