Insert Geometry Can Make All the Difference

One customer challenged Guhring to help them achieve a better surface finish at the boring stage.

One customer challenged Guhring to help them achieve a better surface finish at the boring stage.

The process was a pretty common series of operations: Bore out the part with a turning tool, apply a reamer, then a polishing tool.

A manufacturer of custom arms was frustrated with commercially available reloading equipment and made the decision to branch out into making precision components for reloading ammunition. One component, a case sizing die, requires a very smooth surface finish on the bore of the part.

Working in stainless steel 17-4 PH on a coolant-fed CNC lathe, the manufacturer was able to create a good surface finish by first boring out the part with an indexable boring bar, then following up with a reamer. For the final finish a polishing tool was applied. The challenge given to Guhring’s rep was to achieve a better surface finish at the boring stage, with the end goal of improving the tool life of the expensive reamer and the polishing tool.

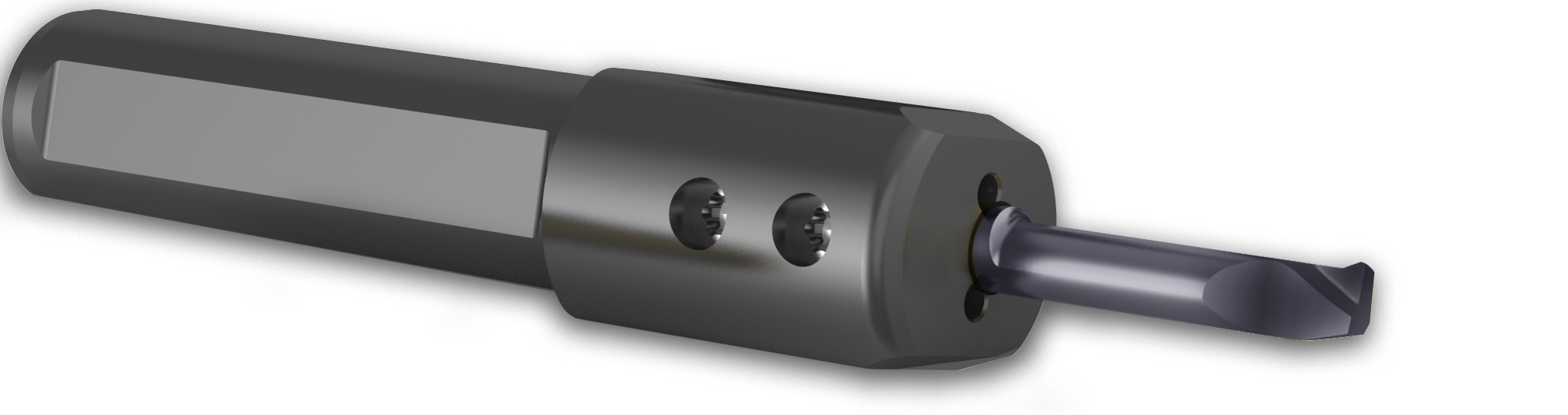

At the recommendation of Guhring’s application specialist, a solid carbide boring bar with a wiper geometry – type GJ 106 from Guhring – was brought in to test in the application. The original indexable boring bar, with a negative rhombic insert, was leaving a finish of Ra 100-120 for the reamer to clean up, and was boring out 20 parts before needing indexing. Each part measures 3", and has a hardness of 30 to 36 HRc.

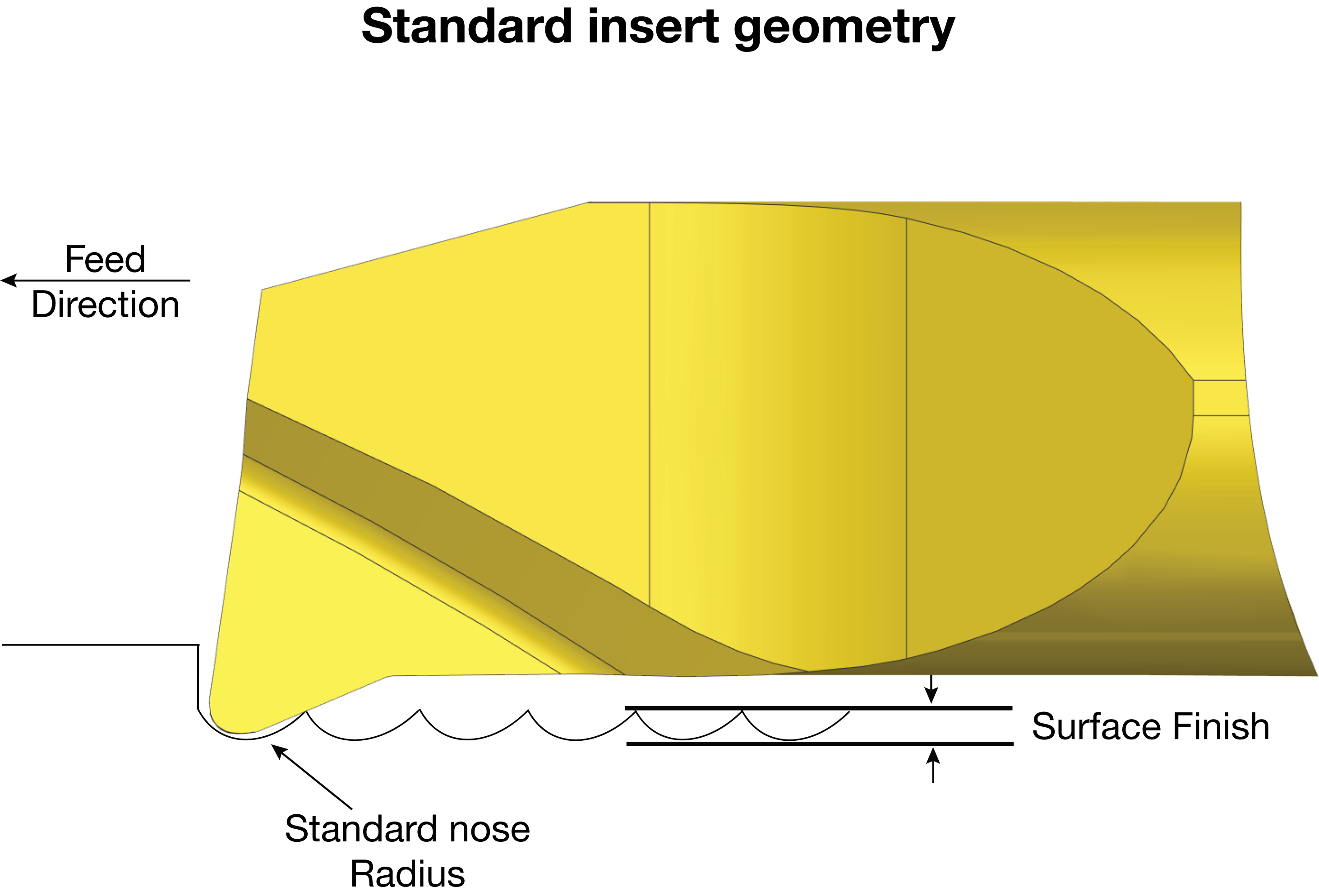

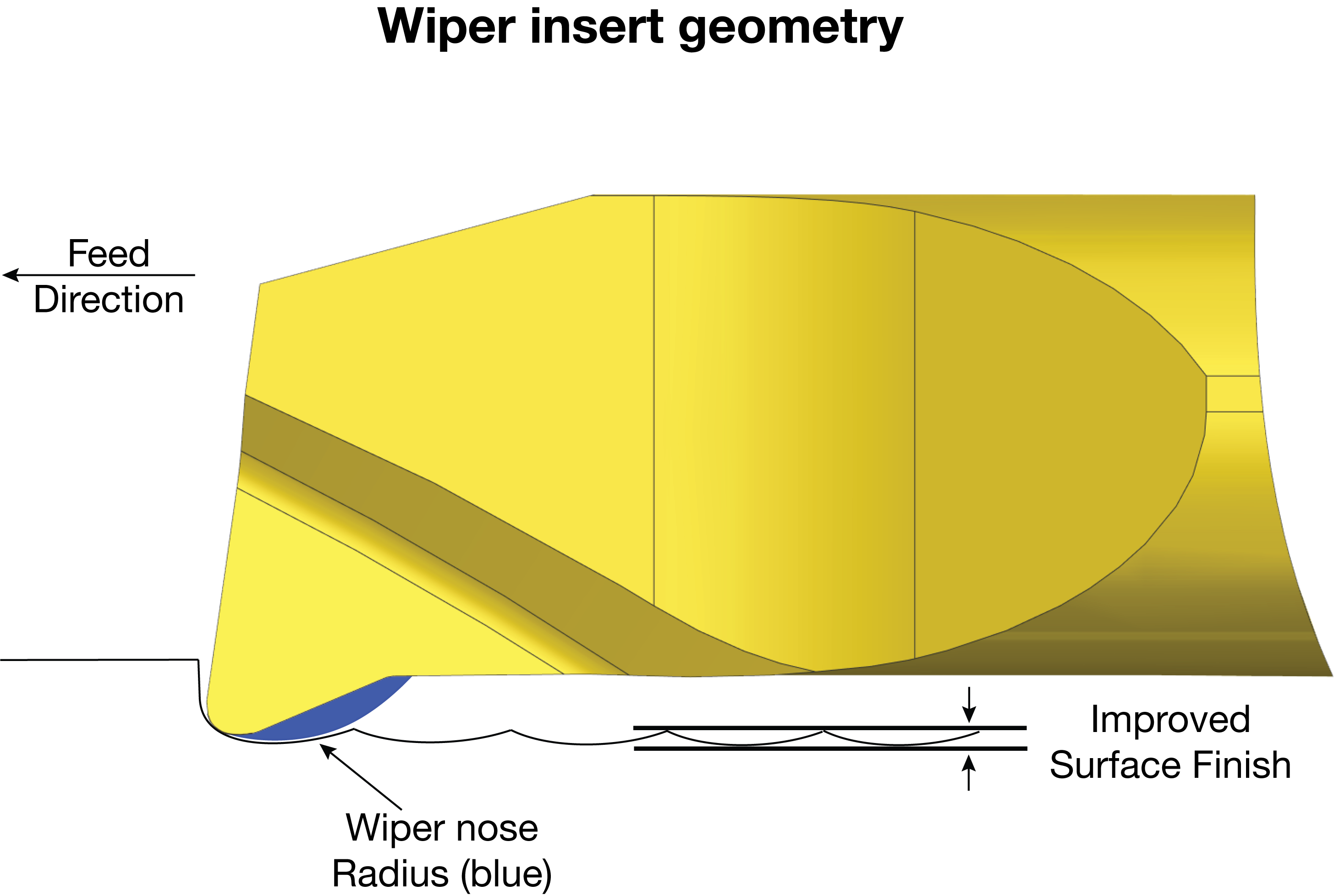

Wiper geometries are not new to cutting tools, but when utilized appropriately they can make a huge difference in surface finish. The key is the nose radius of the insert: an extended radius geometry creates less of a “scallop” with each pass and leaves behind reduced grooves on the surface. Not all boring operations are well-suited for a wiper geometry – the additional axial tool pressure from having a larger engaged surface can cause deflection and even surface hardening from the additional heat generated.

The machinist and Guhring’s rep took a lot of time adjusting the SFM and IPR for the boring application in order to achieve the best surface finish while improving productivity. The Guhring boring bar with wiper geometry completed 50 parts before needing to be replaced, and achieved a surface finish of Ra 30 or better. The cycle time was also reduced from 90 seconds per part to just 51 seconds per part. The wiper geometry on the Guhring boring bar allows for improved chip formation and chip breakage, which also enabled the manufacturer to increase the feed rate and therefore reduce cycle time.

Simply by replacing the indexable boring bar with the Guhring solid carbide boring bar the customer was able to achieve a 26% cost savings. Additional savings were realized by completely eliminating the reamer and polishing operations. In the photo above, you can see the smooth finish on the bore of the part after the boring operation, prior to the polish tool application.

For more than 100 years, Guhring® has provided innovative solutions for round cutting tools. Guhring's extensive line of cutting tools are manufactured on machines and equipment designed and built by Guhring, ensuring the highest level of quality, accuracy and consistency. From micro drills and deep hole drills to cutting taps and finishing end mills, Guhring has the right solution for every job.