Top Benefits of Disposable Cleanroom Coveralls & Aseptic Donning Techniques

Ensuring a sterile environment is crucial in various industries such as pharmaceuticals, biotechnology, and medical device manufacturing.

Ensuring a sterile environment is crucial in various industries such as pharmaceuticals, biotechnology, and medical device manufacturing.

Ensuring a sterile environment is crucial in various industries such as pharmaceuticals, biotechnology, and medical device manufacturing. Ansell’s range of cleanroom coveralls plays a vital role in maintaining these sterile conditions. This blog post will explore the differences between disposable and reusable cleanroom coveralls, the importance of aseptic donning, and the benefits of Ansell’s high-quality disposable coveralls.

People are the biggest cause of contamination in cleanrooms. Therefore, it’s critical to wear the right coveralls to maintain cleanroom standards. When selecting cleanroom coveralls for life sciences applications, it’s important to recognize the fundamental differences between reusable and disposable coveralls to make an informed choice.

By selecting the appropriate garment for the application, employers can protect their valuable products and processes from harmful particles and ions. This improves product integrity and minimizes risk while protecting their workforce with appropriate PPE.

Factors | Disposable Coveralls | Reusable Coveralls |

|---|---|---|

Material & Post-Processing | Made of polyethylene film outer layer and non-woven polypropylene inner layer. Or Spunbond/Meltblown/Spunbond (SMS) material. Sterilized once by gamma irradiation without water usage, maintaining garment integrity. | Made of woven polyester, sterilized multiple times by gamma irradiation or autoclaving, and washed in deionized water. Repeated irradiation cycles cause fiber breakdown, fabric relaxation, and increased pore size, reducing effectiveness. |

Bacterial Filtration Efficiency (BFE) | Not applicable on garments with a laminated material structure. SMS material provides 95% BFE. | Initially <70% BFE, but drops to <40% after multiple washes, increasing contamination risks. |

Chemical & Particle Protection | Provides TYPE 6 limited protection against liquid spray and splash, and TYPE 5 protection against solid particulates. Designed to prevent skin particles, hair, lint, and other contaminants from escaping. | Not effective against chemical protection—substances can easily penetrate the fabric, leading to contamination risks. |

Repairs & Rental Agreements | No repairs or rental agreements needed—one-time purchase with no hidden costs. | Requires frequent repairs for even minor damage and involves long-term rental contracts with fixed weekly costs, regardless of usage. |

Cost Considerations | Lower upfront cost, but ongoing purchase is required. | Higher initial investment due to rental/laundry contracts but may be cost-effective over time. |

Environmental Considerations | Generates waste after each use, but modern disposable coveralls are designed to reduce material usage while ensuring contamination control. | Requires high water and energy consumption for repeated washing and sterilization. While it reduces waste generation, the long-term impact of laundering chemicals and resource usage should be considered. |

Disposable cleanroom coveralls are crucial for minimizing cross-contamination and offering superior chemical protection. Classified as Class III PPE, they provide a flexible, no-commitment solution for adjusting quantities and sizes. They also come with consistent performance, physical characteristics, and recycling options, depending on your business or location.

The EU GMP Annex 1 guideline, updated on August 25, 2022, emphasizes quality risk management and contamination control in aseptic processing. It provides comprehensive guidance on maintaining sterility in medicinal product manufacturing.

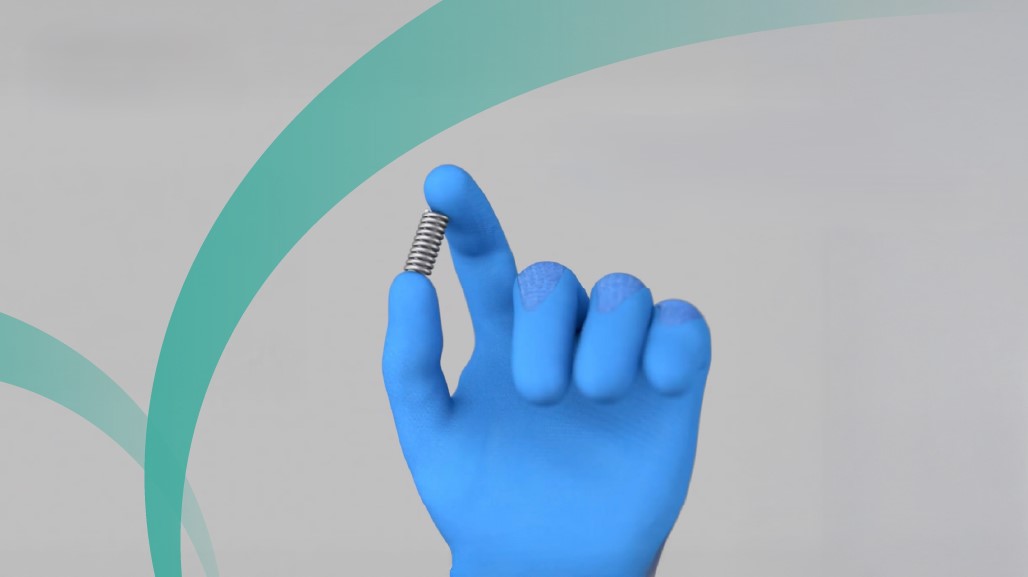

Aseptic donning is crucial for maintaining sterility. Using Personal Protective Equipment (PPE) properly minimizes contamination risks during gowning. Adhering to specific protocols ensures the integrity and safety of both products and cleanroom environments.

Ansell's aseptic donning method for cleanroom coveralls is a recommended approach to minimize contamination during the gowning process. Ansell's donning guides, available in static and video formats, show how to don cleanroom coveralls according to strict guidelines stipulated in Annex 1. Operators are only allowed to touch the inner surface of the cleanroom coverall when donning.

Watch this video to see Ansell's innovative garment fold technique that enables true aseptic donning, enhancing your cleanroom safety and efficiency.

Ansell's aseptic donning method offers several advantages to the pharmaceutical industry, including:

Minimizing Contamination: The method ensures that operators only touch the interior surface of the cleanroom coverall during the donning process, minimizing cross-contamination risks.

Easy to Follow: The method is straightforward, with clear instructions provided in static and video formats, ensuring operators are properly trained to don the coveralls aseptically.

Maintaining Product Integrity: The method and Ansell's cleanroom coverall packaging minimize cross-contamination, protecting the integrity of products manufactured in aseptic environments.

Ansell offers a comprehensive line of protective clothing specifically designed to meet the diverse needs of cleanroom environments. These products are engineered to provide reliable protection, exceptional comfort, and ease of use. All coveralls in the BioClean-D™ series feature an innovative material, making them lightweight and low-linting. The construction of these coveralls includes bound seams with single stitching.

Here is a brief overview of Ansell's BioClean-D™ cleanroom coveralls:

BioClean-D™ S-BDCCT: This sterile coverall features a high neck collar that needs to be worn with a hood and overboots.

BioClean-D™ S-BDFC: This sterile coverall with hood features integrated boots with slip-resistant soles for added workplace safety.

BioClean-D™ S-BDCHT: This sterile coverall is designed with an integrated hood that needs to be worn with overboots.

BioClean-D™ Drop-down Sterile Garment with Hood S-BDSH: This sterile coverall boasts drop-down design technology, preventing needless external surface contact, and is equipped with quick-release tabs and internal colored tabs, indicating safe touch points that further ensure aseptic donning.

These coveralls are just a few examples of the extensive range of protective clothing offered by Ansell, designed to cater to a variety of needs in the pharmaceutical and medical device industries. By combining their high-quality protective clothing with the aseptic donning method, operators can maintain a sterile environment and ensure the safety and efficacy of pharmaceutical products.

Ansell's sterile PPE is double or triple-bagged in durable plastic packaging to reduce contamination, and sterilization indicators show that the PPE has been sterilized to a Sterility Assurance Level (SAL) 10-6. Certificates of Irradiation (Gamma irradiation sterilization) or Certificates of Processing (Ethylene oxide sterilization) per product lot number can be downloaded via Ansell's easy-to-use certificate tool on Ansell's certificate tool page to prove the PPE has undergone the full sterilization process.

Ensuring a sterile environment is critical to prevent contamination and maintain product quality and safety. The EU GMP Annex 1 guideline provides stringent requirements for aseptic processing, including proper gowning guidelines. By following the Annex 1 guidelines and utilizing Ansell's cleanroom coveralls and packaging, operators can maintain a sterile environment and uphold the safety and efficacy of pharmaceutical products. Ansell's aseptic donning method is a recommended approach to minimize contamination during the gowning process, providing several benefits to the industry, including minimizing contamination, being easy to follow, and maintaining product integrity.

Explore Ansell's extensive range of disposable cleanroom coveralls, each crafted to support the highest standards of cleanroom performance and worker safety. Discover their innovative and protective clothing solutions at Ansell’s Life Sciences Protective Clothing.

Previously Featured on Ansell's blog.

Ansell manufactures innovative products that provide unmatched quality, comfort and technology to millions of consumers, workers and first responders. All our gloves benefit from over 100 years of Ansell research and development, patented technology and state of the art manufacturing. Anywhere in the world Ansell helps workers finish their job more safely, more comfortably and more productively.