VIDEO: 60sec Troubleshooting–Threading: Choosing Correct Tap Geometry

When choosing a tap for an operation, not all taps work in all materials.

When choosing a tap for an operation, not all taps work in all materials.

When choosing a tap for an operation, not all taps work in all materials. Learn how to choose a tap specific for your application.

Previously Featured on OSG's YouTube channel.

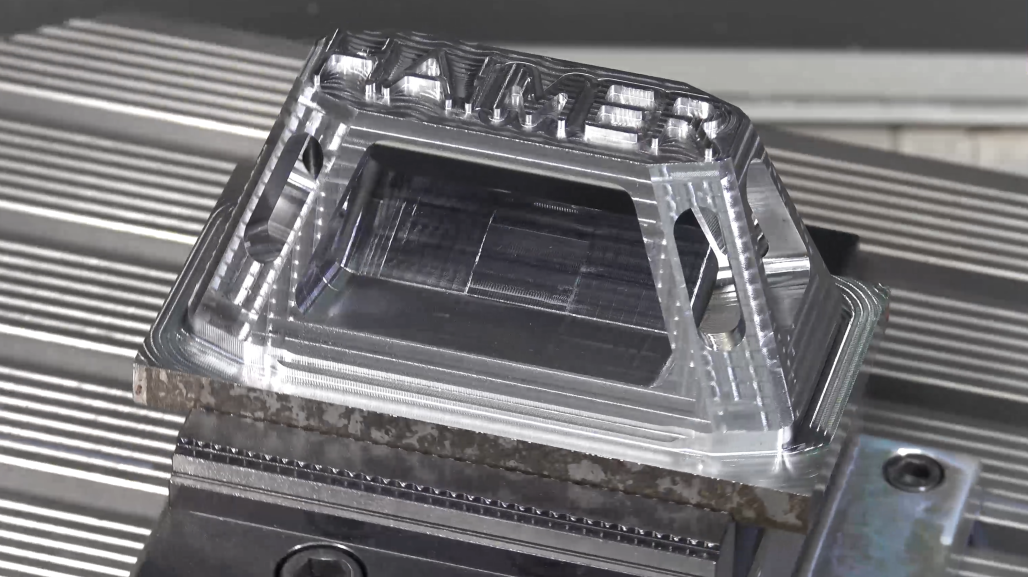

Welcome to OSG's 60-second troubleshooting video. When choosing a tap for an operation, not all taps work in all materials. If the wrong tap is used, it can be catastrophic to the tap or worse, the part itself. It is important to make sure the tap's geometry is correct for the material choice. One example is aluminum. Aluminum is a soft material. A tap with a negative rake angle will have issues due to its blunt cutting edge made for hardened material. When the correct geometry is used, the tap has no issues with the material and works properly over and over again. Thank you for watching. For more information. please visit www.osgtool.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.