VIDEO: 60sec Troubleshooting – Drilling: Drill Runout Signs & Diagnosis

In this 60-second troubleshooting video, OSG discusses drill runout and the role setup plays in optimizing tool life.

In this 60-second troubleshooting video, OSG discusses drill runout and the role setup plays in optimizing tool life.

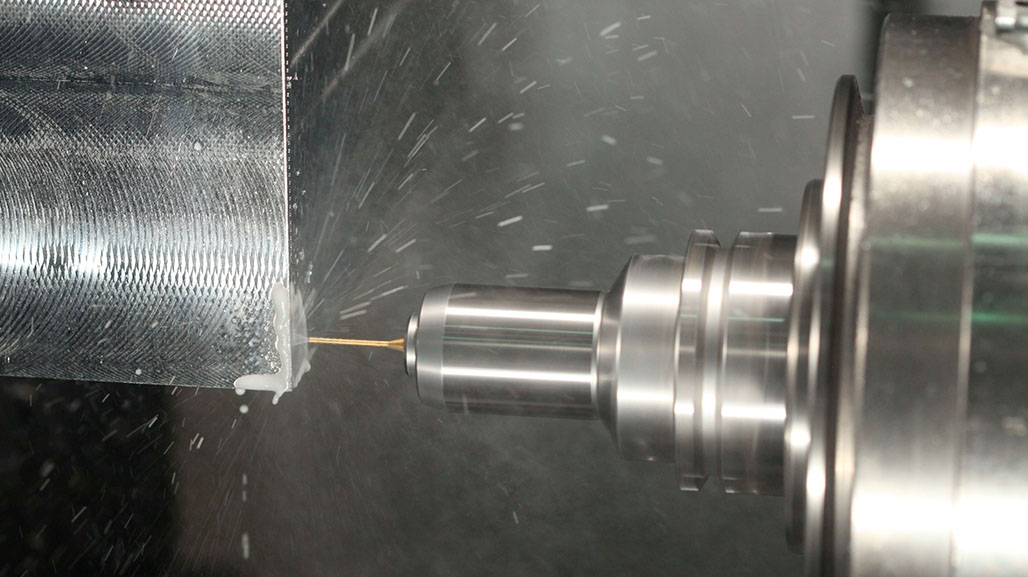

Drill runout is a problem that can occur in machining when the machine or the tool holder is not properly aligned along a central axis, causing the drill to flare out. This effect is more pronounced at the tip of the tool and especially when dealing with long overhangs.

In many cases a key indicator of runout is uneven tool wear, especially towards the margin and shoulder of the tool. Watch the short video above to learn more.

Previously Featured on OSG's YouTube channel.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.