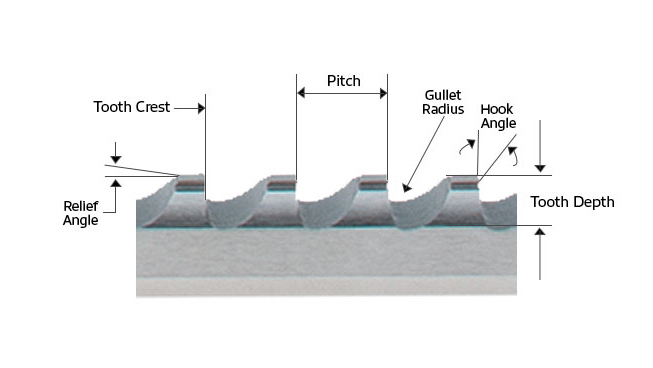

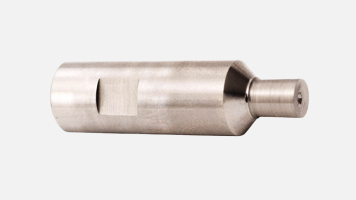

A broach is a bar-shaped cutting tool with a series of teeth that progressively increase in size or vary in shape from the starting end. Each tooth removes a small amount of material as the broach moves through the workpiece in a single pass.

Broach Guide: Types, Tips & Operations

Understand what a broach is, explore the types of keyways and broach styles, receive broaching tips, and learn about the variety of accessories available.

Note: Broach types correspond to specific bushings. For example, a B-1 broach requires a B-1 collared bushing.

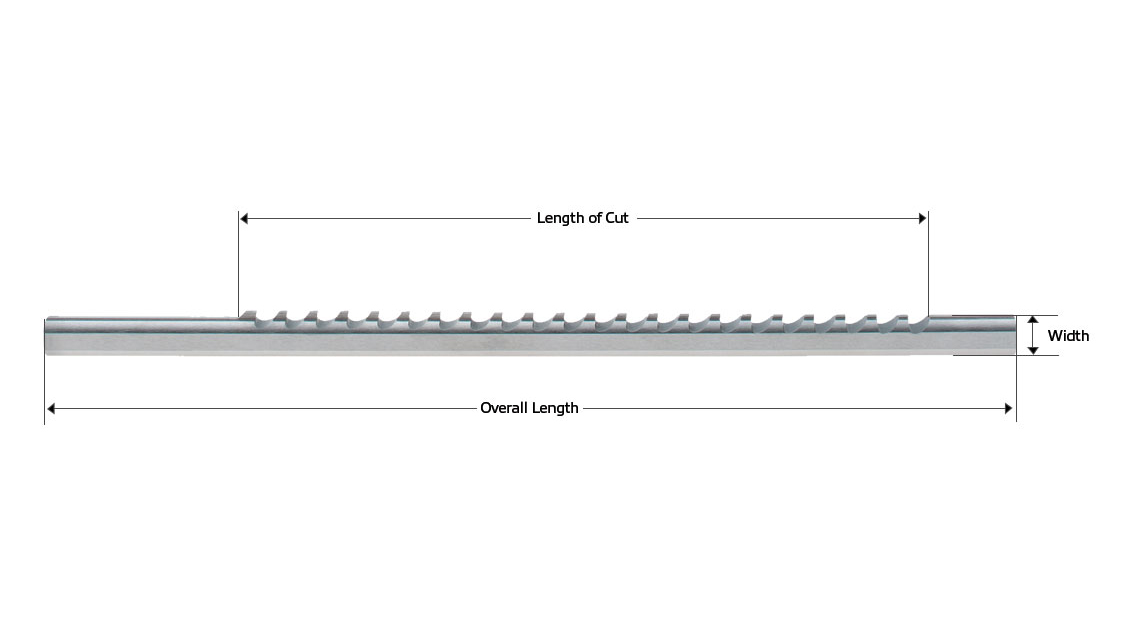

DIAGRAM OF A KEYWAY BROACH

Broaching Tips:

Use materials with a hardness rating up to HRC 38 for the best results. Avoid broaching harder materials, as they can damage the tool.

Align the tool correctly to prevent breakage or drift. Always keep at least two teeth engaged during the cut and use bushings to support the broach and maintain accuracy.

Apply proper lubrication to reduce friction and improve chip removal.

After each pass, use a stiff brush to clear chips from the cutting section of the broach.

Types of Broaches:

Keyway Broaches

Cut starter holes, remove material, and shape workpieces in a single pass. These broaches feature a bar-shaped design with multiple teeth that progressively increase in height or shape from the starting end. A keyway broach leaves a polished finish on the final product and helps save time and improve efficiency, especially when used with a compatible bushing. Keyway broaches sets are also available.

Square Broaches

Cut square holes in one pass while removing minimal material. They typically have an oversized pilot that leaves drill marks in the flats to provide relief while establishing four corners in a hole. The pilot diameter matches the final square size. Use square broaches to enlarge, shape, and finish irregular internal profiles in a workpiece.

Hexagon Broaches

Create hexagon-shaped holes while removing a small amount of material in a one-pass operation. Like square broaches, they work well for enlarging, shaping, and finishing irregular shapes in a workpiece.

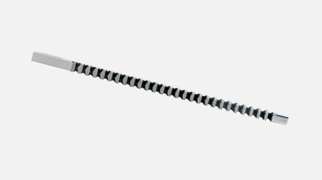

Rotary Broaches

Quickly form polygonal shapes in a single pass. They are ideal in the automotive, aerospace, and medical industries.

Round Broaches

Cut round-shaped holes in a single pass and use a variable pitch to improve precision.

Types of Keyways:

Broaching Operations:

- Internal operations transform a round-drilled hole into any configuration, using either a push or a pull broach. Most applications use push broaches, but pull broaches (like AF Stock) offer longer lengths of cut when broaching square and hexagon shapes. Common applications include tooling fixtures, gear and pulley keyways, rifling, and all hole configurations.

- External (surface) operations replace milling or shaping by producing precise dimensions at higher speeds. Typical examples include flats, notches, keyways, contoured surfaces, external gear teeth, and serrations.

Broach Material & Finishes:

- High Speed Steel (HSS) broaches offer solid wear resistance and are ideal for general-purpose use across both ferrous and nonferrous materials.

- Bright Finish broaches feature a smooth, polished surface that enhances chip flow in softer materials such as aluminum, wood, and plastic.

- Titanium Nitride (TiN) coated broaches improve chip evacuation in softer materials and deliver better wear resistance and thermal stability, allowing the tool to run at higher speeds than uncoated tools.

- Titanium Aluminum Nitride (TiAlN) coatings increase surface hardness and oxidation resistance, making these broaches ideal for high-speed operations in a variety of steel machining applications.

Broach Accessories:

Broach Bushings

Broach bushings are metal slotted liners that support and guide the broach during cutting. They come in plain or collared types, with collared bushings offering easier use in smaller holes. You can also find broach bushing sets specifically for keyway broaches.

Broach Shims

Broach shims are thin metal pieces that help achieve the desired keyway depth in a bore.

Rotary Broaching Setup Plugs

Rotary broaching setup plugs simplify blind hole broaching by eliminating guesswork. Operators typically use these plugs with rotary broaches and broach holders.

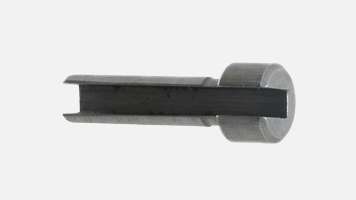

Rotary Broach Holders

Rotary broach holders securely hold a variety of broach shapes, including hex and square. Their internal spindle design makes them compatible with CNC machines, manual lathes, milling machines, and screw machines.