Fast, Reliable Inspection with Go/No-Go Gauges

Understand how Go/No-Go gauges work, what types are available, and how to use them to maintain quality standards.

Go/No-Go gauges are widely used in manufacturing and machining to verify that components meet quality standards during production. These rather inexpensive tools provide a quick and reliable pass/fail result rather than an exact measurement.

A typical Go/No-Go plug gauge assembly includes:

A Go gage pin (tolerance plus), which represents the minimum acceptable hole size

A No-Go gage pin (tolerance minus), which represents the maximum acceptable hole size

A handle and two bushings to secure the pins

If the Go pin fits into the hole and the No-Go pin does not, the part is within tolerance. If both fit or both fail, the part is rejected.

Types of Go/No-Go Gauges

Plug Gauges

Plug gauges, also called pin gauges, inspect the diameter or threads of manufactured holes in machined parts. They consist of a cylindrical pin that includes:

- A Go pin end that should fit into the hole (minimum acceptable size)

- A No-Go pin end that should not fit (maximum acceptable size)

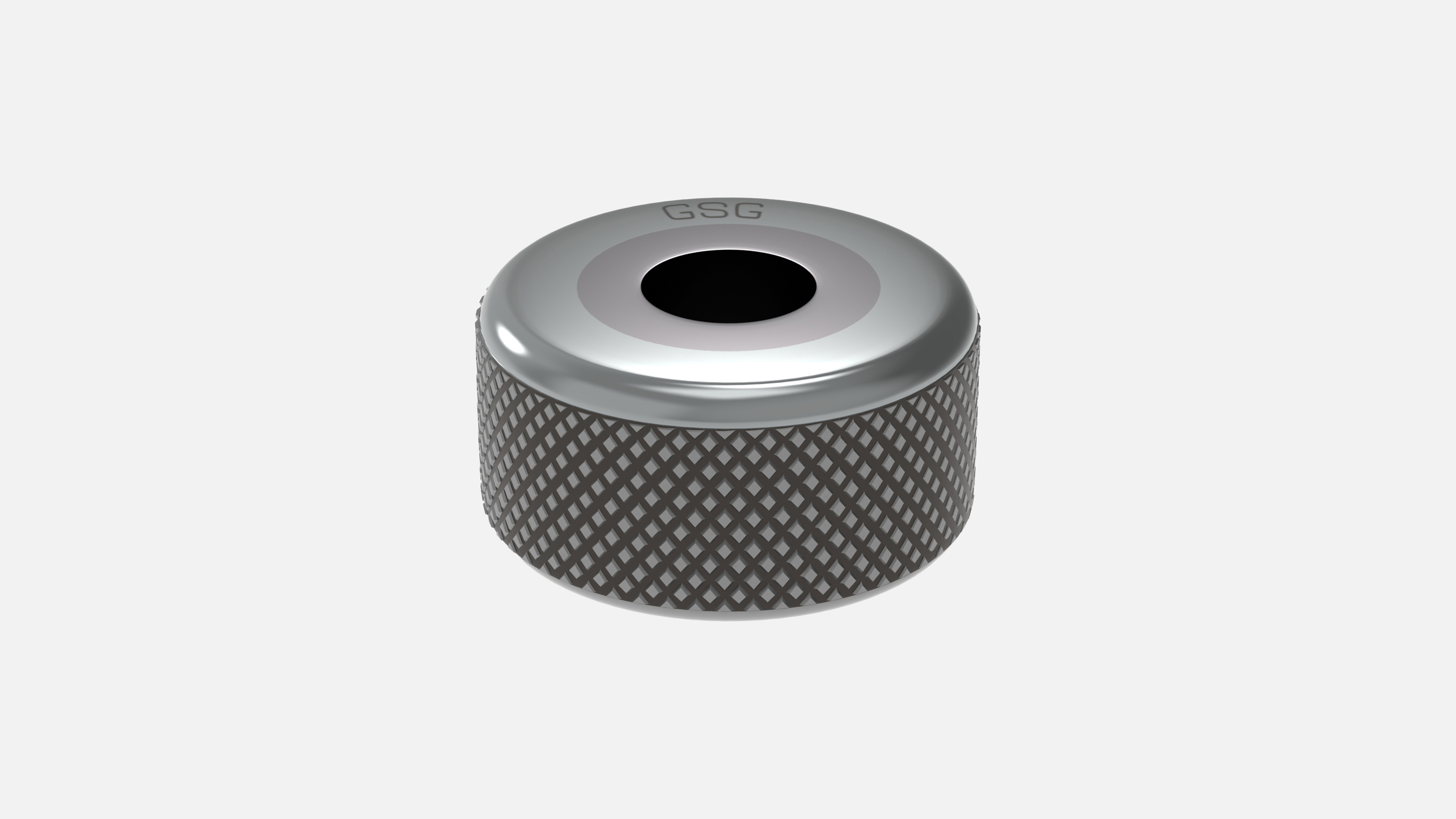

Ring Gauges

Ring gauges check that the outside diameter or external threads of cylindrical components, such as shafts and rods, are within tolerance.

- The Go ring must slide onto the part

- The No-Go ring must not fit if the part is within tolerance

Snap Gauges

Snap gauges are open-frame gauges that consist of two jaws used to measure external dimensions quickly.

- The part passes through the Go slot

- The No-Go slot stops parts that are too large