Composite Toe vs. Steel Toe Safety Boots: Complete Comparison Guide

Trying to decide between composite and steel toe caps in your safety footwear? Here are several factors to consider.

Trying to decide between composite and steel toe caps in your safety footwear? Here are several factors to consider.

For most of the past 90-plus years, steel was your only choice when you needed safety toe cap footwear. But recently, alternative materials have entered the market, making it more difficult to know the right foot protection for the job.

“I don’t think anybody can point to a specific event that said, ‘Aha! We need to change from steel to an alloy or from steel to composite,’” says Rob Petersen, director of product and portfolio management at Tingley.

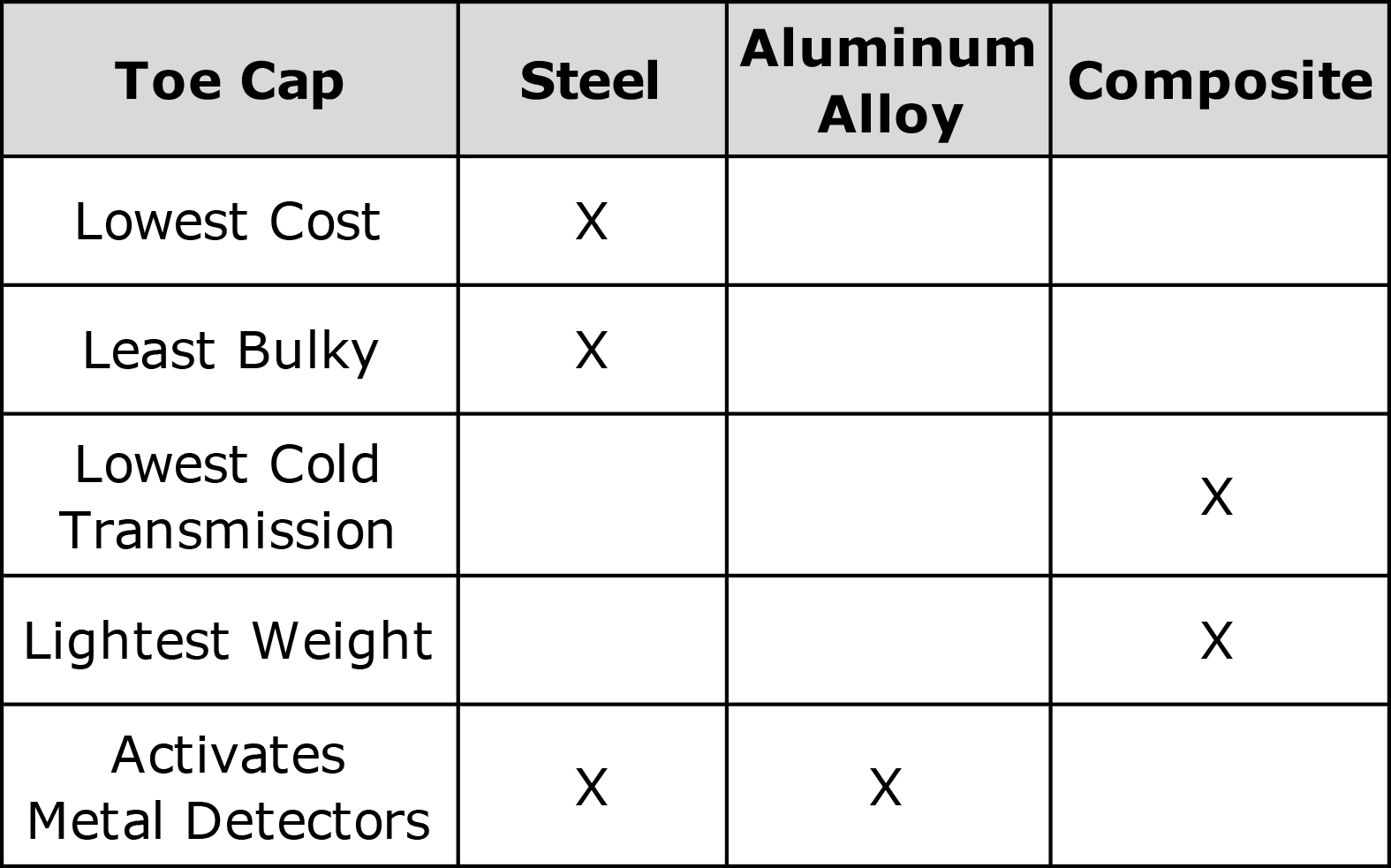

Rather, it’s been a progressive shift over the years. In a white paper on the subject, Petersen explains that steel has been used for toe caps since at least the 1930s; consumer desires for lightweight boots have led to the development of toe caps made from aluminum alloy and, in the past decade or so, composite materials such as polycarbonate, fiberglass and carbon fiber.

People often wonder whether composite toe cap footwear or steel toe cap footwear is best. It helps to compare them by their protective abilities and applications.

The Occupational Safety and Health Administration requires that safety footwear comply with ASTM F2413, a consensus standard published by ASTM International.

“It’s a fairly comprehensive standard as far as assessing the parameters for safety footwear,” Petersen says. “And it governs all kinds of things: toe impact, toe compression, puncture resistance, metatarsal guard, some electrical hazard safety levels.”

According to Petersen, the two main criteria for toe caps are:

Impact force—protection against falling objects

Compressive force—protection against crushing, such as from heavy rolling objects

Because ASTM F2413 is a pass-fail standard, safety footwear either passes or it doesn’t, regardless of whether the toe cap material is steel or composite. “Both will provide you with the same degree of protection,” Petersen says.

“If the footwear is labeled with ASTM F2413,” he says, “then you know that the footwear has been tested and assessed according to those minimum performance specifications.”

The job environment is a key factor in deciding between steel and composite toe caps.

In cold regions or refrigerated spaces, for example, composite toe caps often have an edge over steel.

“We’re finding the composite toe caps are preferred because they tend to transmit that cold environmental temperature to the interior of the shoe, where your toes are, at a slower rate than a steel toe cap would. So, people find composite is a little bit more comfortable.”

In electrical settings, there is not much difference between steel and composite toe caps, Petersen says. “Some people might say a steel toe cap is going to conduct electricity a little bit better or faster, but that’s not necessarily the case,” he says.

“As long as the footwear has the ASTM label and it has the EH designation on it—that’s the electrical hazard designation—then whether it’s a steel toe cap, an aluminum toe cap or a composite toe cap, it’s passing that electrical hazard testing and performance requirements.”

Read more: Modern Safety Shoes Beef Up Protection While Shedding Weight

Weight differences between composite and steel are also negligible, thanks to advances in material technology.

“Steel is inherently a very strong material, so you can make it fairly thin and achieve the impact and compressive performance specifications that you’re looking for,” Petersen explains. “On the other hand, composites are very good, but to do the job, they tend to be a little bit thicker than steel. If we were to put a steel toe cap and a composite toe cap on a scale, the weight difference is really not that large. It’s a tiny bit lighter still for the composites.”

As material technology improves, Petersen says, composites will become lighter—while maintaining impact and compression resistance—and the weight gap may widen between composites and steel, making composites a preferred option for comfort during long shifts.

Facilities that require workers to go through metal detectors, such as food plants, may benefit from footwear with composite toe caps.

“Composites are not going to set off the metal detectors,” Petersen says. “The steel toes will, and then it’s just a little bit of extra time to have to go and wand that person.”

Composites also will not rust or corrode like steel, making them an attractive choice for harsh or wet environments.

Read more: Safety Shoes: Are You Using the Best PPE Footwear in Your Facility?

Considering the straight cost of toe cap materials, steel is slightly more affordable compared with composites. Plus, for certain footwear categories, such as injection-molded waterproof boots, composite toe caps require specialized manufacturing, which adds to the cost.

Before you go right to the lowest-cost product, however, be sure to consider the total cost of ownership, something that smart employers are doing for all of their purchases, whether they’re buying raw materials, tools or personal protective equipment such as safety footwear.