Performing regular maintenance checks of your equipment is necessary to keep it operating efficiently and extending its life. Here are best practices for managing costs, ensuring worker safety and upgrading and preserving equipment during these periods.

Temporary shutdowns—whether for planned equipment maintenance or due to a period of slower demand—are common in manufacturing.

During these times, some equipment—or even the whole plant—must be shut down entirely. This can be a very expensive undertaking, given that no income is generated for your facility. Yet the short-term cost to your business can be offset by better plant efficiency, less energy use and fewer unexpected mechanical failures.

Shutdowns should be planned carefully to minimize their impact on your business, so it’s important to create a plan that suits your team and operational needs.

There are several factors to consider when devising a plan. How long will the shutdown take? Does it affect only part of the factory—a dedicated machining cell, perhaps—or is it plantwide? Or maybe it’s just a response to a temporary drop in orders and the management is looking for ways to keep employees busy rather than sending them to the unemployment line.

Coolant and Sump Pump Maintenance

Whatever the scenario, you’ll usually want to give your cutting fluids and machine sumps some special attention before sending everyone home.

Two people who know all about this are Dean Richmond, global aerospace sales manager for Master Fluid Solutions, and Jim Brumgard, an application engineer at BP Lubricants USA Inc.’s Castrol Industrial unit. Both have decades of experience, and both will tell you that an idle sump is a prime breeding ground for the bacteria that causes dermatitis and Monday morning stink.

Read more: Machine Coolant Sump Cleaning: What to Do When Production Slows

“Coolants need to move around, and even a well-maintained sump will go rancid if left unattended for weeks on end,” Richmond says. “Probably the simplest thing to do in this situation is to have someone come in every few days, turn on the machines, and let the pumps run for an hour or so. This not only aerates the cutting fluid but also coats the machine surfaces, giving the rust preventative a chance to protect them against corrosion. It’s also a good idea to balance the pH, check the alkalinity and possibly bump up the concentration levels a few percent, as this helps reduce bacteria growth.”

Brumgard agrees, adding that if these machines have turn-on procedures that include a preprogrammed routine to get the spindles turning, the guideways moving, and the toolchangers changing, those procedures will go a long way toward preventing possible future damage to bearings and other mechanical components.

“Just as cutting fluids should be cycled periodically, so should machine tools,” he says. “It introduces fresh way oil and hydraulic fluid into the system and gets everything lubricated again.”

This might also be an excellent time to thoroughly clean each sump, they suggested, and spend some time wiping down the rest of the machine as well.

Both experts had additional recommendations. These include activities like replacing the desiccant within the breather cap on each hydraulic reservoir, as well as topping off the reservoir itself, together with its way oil counterpart. And assuming you institute the routine mentioned earlier, don’t forget to check the fluid levels periodically—just because the machine isn’t making parts doesn’t mean it’s not consuming fluids. With that, of course, comes cutting fluid contamination, as spent lubricants make their way into the sump. The solution is to make sure that each machine’s skimming unit (an accessory that all facilities should be using) is in good working order.

Of course, the lengths to which a shop must go to maintain idle equipment depends on the time of year and where that equipment is located.

Climates such as Houston in August will be more likely to cause humidity-related problems than Minneapolis in the dead of winter. On the flip side, static discharge is more of a concern in dry environments, which is one reason why CNC machine tools should be properly grounded, idle or not. Both of these situations can be eliminated by maintaining consistent temperatures and humidity levels via a climate control system, something that’s a good idea for any shop interested in part accuracy and worker productivity.

There are other suggestions that, again, depend on the expected downtime duration. For example, it’s never a good idea to leave toolholders in machining center spindles over the weekend, but for extended work stoppages, all vises, fixtures, toolholders, turret blocks, rotary tables and the like should be removed from the machine tool, cleaned and lightly lubricated, then stored in the tool crib. It might seem like a lot of work, but they also cost a lot of money to replace.

Create and Work Through a Machine Shop Maintenance Checklist

Shops aren’t always “down.” Sometimes they’re just slow. When this happens, it’s a great time to get everyone busy on oft-neglected preventive maintenance activities. Brumgard and Richmond will tell you that sump cleaning and coolant maintenance should be part of this, but just as it is at home, most shops have an industrial equivalent of the honey-do list.

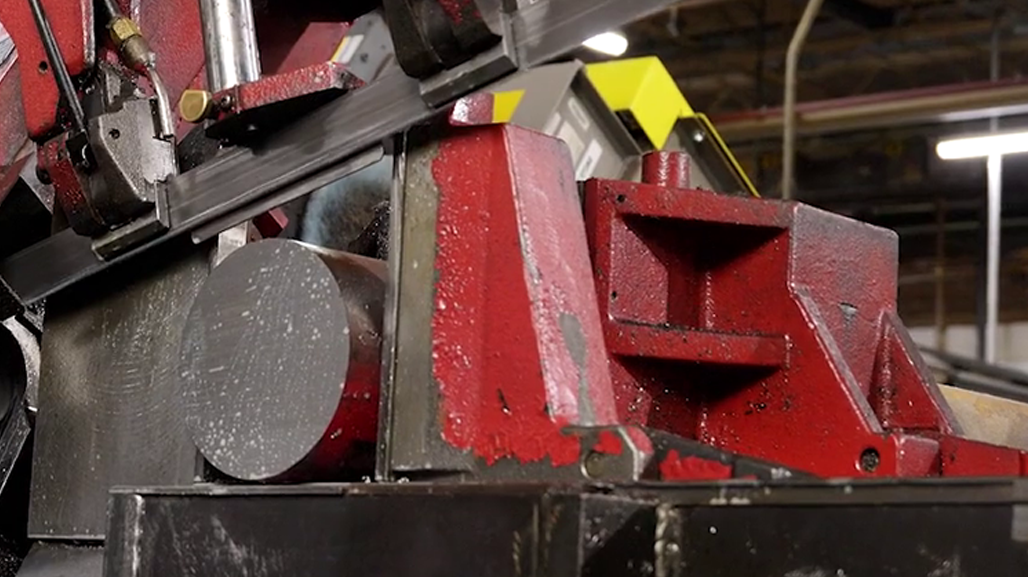

Been thinking about painting the shop floor? Now’s the time. Same with the walls, the break room, and while you’re at it, how cool would it be to have a supersized version of the company logo on the wall outside the office? There’s rebuilding the air compressor, maintaining the delivery truck, replacing the wheels and guides in the band saw, catching up on operator safety training, calibrating all of the gages and micrometers in the inspection room, laser shooting the CNC lathes and machining centers … no different than at home, it’s probably a long list.

When your list of tasks is done, you’ll have that warm fuzzy feeling we get after cleaning out the garage or washing and waxing the car. In this case, however, your shiny new shop will give your customers and prospects that same feeling, potentially attracting even more work.

So get busy working the list—the slowdown is probably only temporary.

How to Tool Up for a Tune-up

As it is when a shiny new CNC machine tool hits the floor, maintenance and repairs around the shop require that you “tool up” with the right equipment.

Each manufacturer is different, but here are a few of the things you should have on hand:

Painting supplies: Ready to paint the shop red (or blue, green and purple)? You’ll need paint, of course, but also sandpaper, masking tape, patching compound, rollers and brushes (or better yet, a sprayer), plastic dropcloths … you get the idea.

Lockout/Tagout: Most shop equipment carries enough current to present the risk of electrocution and death. A lockout/tagout station and accompanying procedures are a must if you’re going to be digging inside electrical cabinets.

Spare parts: Replacing the wire cutter, guides, filters and flush nozzles on the shop’s wire EDM? Nothing is worse than having an expensive machine torn apart only to find you’re missing a critical component.

First-Aid kits: Accidents happen, especially when people are performing tasks to which they are unaccustomed. Be sure there are plenty of Band-Aids, gauze, tape and eye dressings on hand, along with a good dose of common sense.

There’s plenty more, including lubricants and rust preventative, wheels and dollies if you’re going to be moving equipment (probably better to hire a rigger), the appropriate cleaners for those planning to tackle their coolant sumps, along with plenty of floor-dry.

And to do these jobs most effectively, all these items should be well-organized, stored neatly in toolboxes and bins, and waiting on labeled shelves, ready to get to work.

Related Articles in Facilities & Operations

Preventing Workplace Injuries From Equipment Failure

Illumination Best Practices: Your Guide to OSHA’s Lighting Standards

VIDEO: TOOLING UP – Faster and Safer Electrical Testing with Innovation From Fluke

HOW TO Minimize Downtime in Your Shop