OSG’s NEW HY-PRO® CARB VGM End Mills for Dynamic Milling

OSG's HY-PRO® CARB VGM end mill is a series of variable geometry end mills for dynamic milling ideal in steel and stainless steel.

OSG's HY-PRO® CARB VGM end mill is a series of variable geometry end mills for dynamic milling ideal in steel and stainless steel.

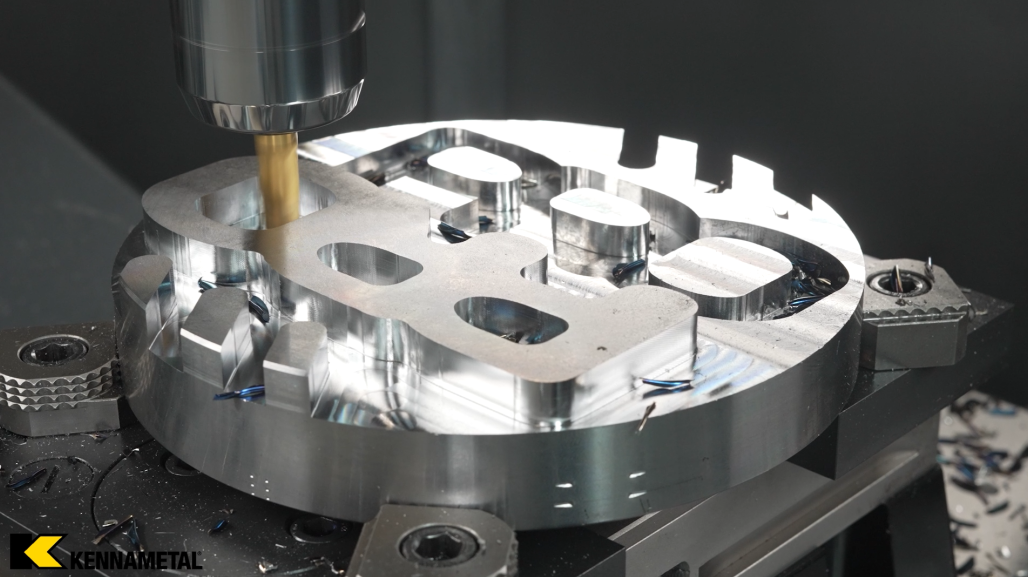

The HY-PRO® CARB VGM Series is OSG’s newest and most impressive release. The HY-PRO® CARB VGM end mill is a series of variable geometry end mills for dynamic milling ideal in steel and stainless steel. Included in this series is 5-flute, 6-flute, and 7-flute end mills.

As dynamic milling has increasingly become more popular, a lighter width of cut is essential, especially in difficult-to-machine materials such as steel, stainless steel, and exotic materials.

With variable index and unique flute geometry, the OSG HY-PRO® CARB VGM series features unequal flute spacing which reduces vibration during machining by altering the timing of each flute engaging in the workpiece. In addition, a sharp rake angle, high helix and adjusted core diameter maintains excellent cutting edge sharpness and tool rigidity to promote smooth, stable cutting with low cutting force.

In just a short couple of months since this tool has been released, OSG has received an overwhelming amount of reviews that include cycle time reduction, increased tool life, and less cost per tool.

Below are some of the customer responses they have received from this series:

Raven Rock Machine Shop was looking to reduce cycle time but still maintain an acceptable finish that would highlight the pride and high quality of their shop. With use of the HY-PRO® CARB VGM5, they saw a three-minute cycle time reduction, while running two parts for an initial first article inspection. Tool maintained service life through 75 parts. The customer was very impressed and they stated it is hard to impress them.

Customer wanted to see reduction in cycle time and increase in tool life after hearing about OSG’s new 5-flute end mill, the HY-PRO® CARB VGM5. They were running a standard 4 flute at 500 SFM and 32 IPM full slotting, 50 IPM side milling. We put the VGM5-0132 in at 550 SFM and 42 IPM full slotting, 60 IPM side milling. The standard end mill would last 9-10 parts before wearing out. The VGM5 lasted 25 parts.

VGM success at a shop with a ¼" VGM5-0070 in 17-4PH Pump Impeller. Customer stated “The VGM sounded much better and the finish was excellent.” The milling process was much improved by changing to VGM, improved finish and stable process. After running a few parts, the end mill still looked new.

½" VGM5 in 304SS against a standard end mill. With the VGM, cycle time was reduced by 10 minutes and more than doubled the tool life! The standard end mill’s tool life was 15 pieces; the VGM5 was able to complete the job at 45 pieces and still looked great. On top of all that, the VGM5 was $10 less than the standard.

You can download OSG's brochure of their VGM Series of end mills to help you find your dynamic milling solution.

To learn more about OSG’s HY-PRO® CARB VGM end mills, visit MSCDirect.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.