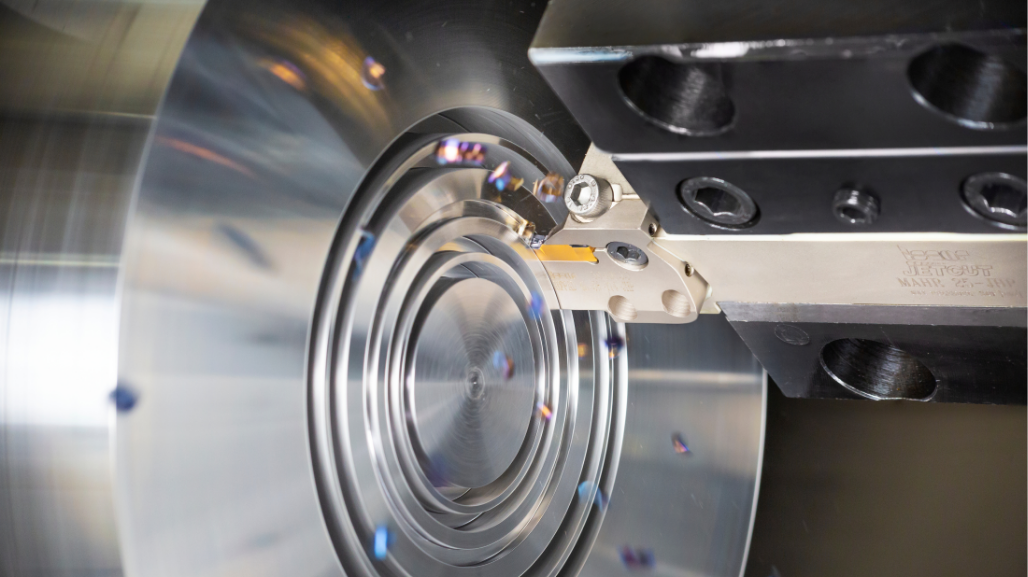

Carbon-fiber reinforced polymer (CFRP) is a popular composite material that has the right mix of weight-to-strength ratio, durability, and extreme corrosion resistance. This makes it well suited for aircraft hulls and wings.

But you know from experience that while composite layers are strong, they also can wear down a tool’s geometry in a matter of minutes and splinter at the edge when machined. Such splintering causes weakness. You don’t want splintering on an aircraft hull or wing.

Your challenge: Find a tool with the right geometry, clearance, and coating to withstand composite wear and eliminate splintering.

Kennametal's solutions: Kennametal tungsten carbide grade KCN05™ with diamond coating for routers and SPF drills. The diamond coating of grade KCN05 preserves the geometry through the cut, so you get consistent, clean edges and finishing. Kennametal SPF drills have been shown to last up to 10 times longer than uncoated solid carbide drills in CFRP applications. Their KCN05 routers are available in down-cut, compression, burr, and ball-nose styles and designed for smooth finishing in CFRP.

To view the full line of products from Kennametal, visit MSCDirect.com.