5 Ways to Make Bandsaw Blades Last Longer

Experts at Lenox say extending bandsaw blade life is all about fundamentals, including proper break-in, the right speed and feed settings, clean lubrication and consistent maintenance.

Experts at Lenox say extending bandsaw blade life is all about fundamentals, including proper break-in, the right speed and feed settings, clean lubrication and consistent maintenance.

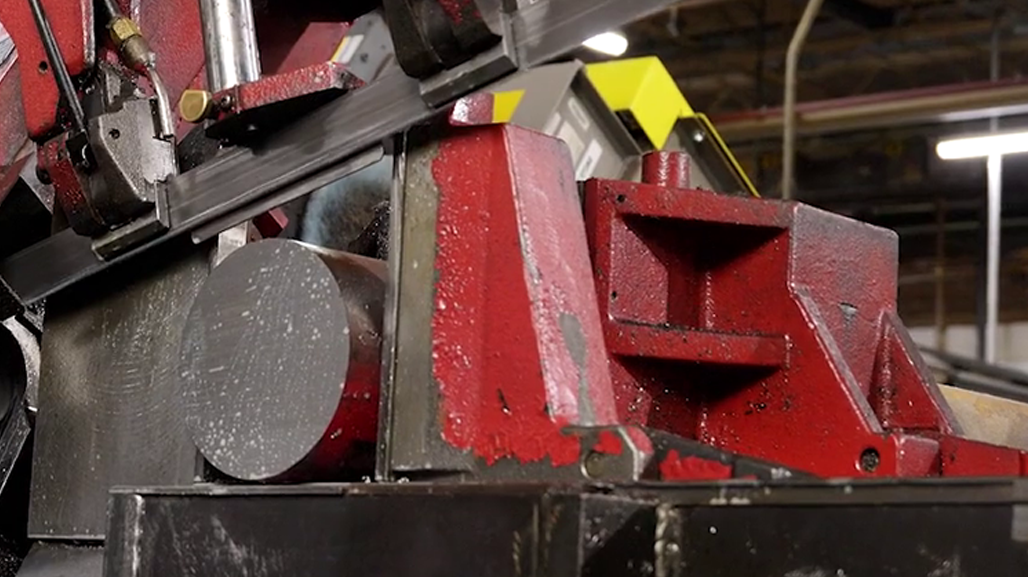

When bandsaw blades wear out too soon, production stalls, scrap piles up and costs rise.

But premature wear isn’t inevitable, says Cameron Guthrie, national account manager with Lenox, the Massachusetts-based toolmaker that’s been in business since 1915. Most bandsaw blade failures aren’t caused by the blade itself but by how it’s being used, he says.

“The biggest mistakes we see are operators skipping the blade break-in process, using the same speeds and feeds for every material and not matching the right tooth pitch to the cross section they’re cutting,” Guthrie says. “Each of those missteps can dramatically shorten blade life.”

Addressing these and other issues can add days of cutting life to every blade. Here are five proven steps machine shops can make to ensure their bandsaw blades last longer.

Breaking in a new blade is essential for durability, Guthrie says.

The break-in process forms a micro-radius on the tip of each tooth, which hones the tooth and prevents microscopic damage to the tips of the teeth. A proper break-in can extend blade life by as much as 25 percent, he says.

“The analogy we use is, if you have a pencil sharpened to a fine point and you push too hard when you begin to write, you will easily break the pencil lead,” Guthrie says. “If you write softly and round over the pencil lead, you can then push harder and prevent the pencil lead from breaking.”

Lenox recommends setting the band speed based on the type of material you are cutting. “The operator should reduce the feed rate and/or pressure by 20 percent to 50 percent of normal and gradually increase the feed rate and pressure over 50 square inches to 100 square inches of cutting,” he says. Harder materials need the shorter break-in; softer materials can go longer.

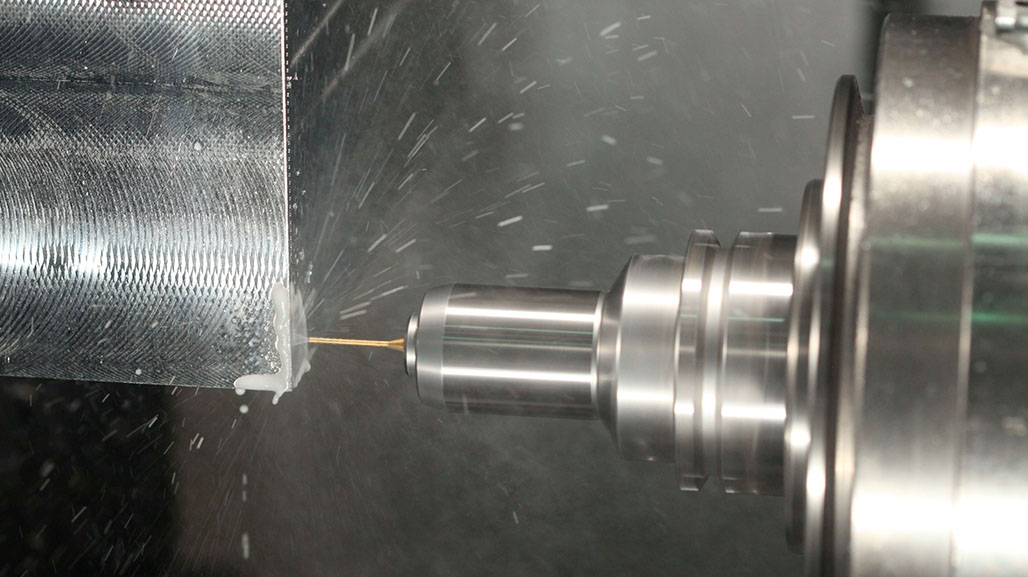

“Heat and vibration are the two worst enemies of blade life,” Guthrie says. The right combination of band speed and feed rate minimizes both, which enables the blade to form consistent, shiny silver chips—“the hallmark of a healthy cut.”

Harder materials need slower speeds and higher feed pressure to bite cleanly, while softer materials can handle faster speeds and feeds. “Watch your chips,” Guthrie says. “A typical chip formed in a bandsaw operation will be shiny and silver in color and in the shape of a spring or a curly 6 or 9, depending on the type of material you are cutting.”

Bandsaw operators also need to keep an eye on gullet capacity, which is the amount of space for chip storage between each tooth. The correct tooth pitch—the distance from the tip of one tooth to the tip of the next tooth—is determined by the cross section of material the blade is cutting, Guthrie says. “If the chip is oval instead of round in shape, or tightly curled instead of a uniform curl, that is an indication you are feeding too fast or have the wrong tooth pitch for the size of the part you are cutting.”

You can slow the band speed down by approximately 10 percent if you are seeing color in your chips or compacted chips. Guthrie says another option is to slow down the feed rate and/or pressure until you see a uniform curl and shiny, silver chips.

Selecting the right tooth pitch for the material and cross section is key, says Guthrie.

“Our rule is that you should have at least three teeth in the work at all times, ideally between six and 12 teeth in the work, and no more than 24 teeth in the work,” Guthrie says. “You can take the average teeth per inch of blade and multiply that number by the size of the cross section to determine how many teeth are in the work at one time.”

Beam strength is another factor. “Ideally, an operator will want to use 50 percent of the saw’s vice capacity in order to keep the maximum beam strength in the blade for production cutting, resulting in square, smooth, accurate cuts,” Guthrie says. This allows the operator to move the guide arms closer to the work piece, increasing beam strength and improving the blade’s ability to counter the resistance of the material during the cutting process.

Using more than 50 percent of the saw’s vice capacity reduces beam strength, causes the blade to deflect and results in cuts that are dished or are not square. “Those cuts are now considered scrap, have to be recut, or machined square, which is obviously additional time and labor,” Guthrie says.

WATCH: Jacob Sanchez, host of MSC Industrial Supply’s How To series, visits Lenox to learn how you can minimize downtime in your shop.

As mentioned above, nothing shortens blade life faster than heat and vibration. “Proper cooling and lubrication allow for maximum blade life by pushing as much heat as possible into the chip and preventing heat from being absorbed by the blade,” Guthrie says.

Many saw sumps are using dirty sawing fluid that is not mixed at the proper ratio, is contaminated with tramp oils or hydraulic oils from the machine, or is full of metal chips. “All of these examples reduce the ability of the sawing fluid to properly lubricate the tooth face during the cutting process,” he says.

Routine checks with a refractometer can help determine if the coolant is mixed properly. In addition, periodically draining the tank, cleaning out the chips and recharging with clean fluid will provide consistent, extended blade life.

“Keeping the coolant mixed at the correct ratio with the proper makeup rate will extend the life of the fluid so you’re using less fluid in the long term,” Guthrie adds.

Routine maintenance has always been essential for optimal sawing performance, but with today’s demanding superalloys, that need has only intensified, according to Lenox.

“Preventive routine maintenance, checking for proper blade tracking, guide wear, blade tension and chip brush use will always result in consistent, long-lasting blade life,” Guthrie says.

Skipping these steps can lead to costly blade failures:

• If the blade is not tracking properly, that can cause blade breakage from the back edge or loss of set on the tooth edge.

• Chipped corners, missing carbide or roller guides, or grooves will result in blade breaks or scoring of the blade.

• Excessive tension can cause blade breakage, and low tension will result in dished and out-of-square cuts.

• A chip brush that’s missing or improperly placed allows chips to carry back around and enter the cut again, which can result in tooth stripping or overall wear and deteriorating condition of the saw.

If your facility is experiencing premature blade failures, Guthrie recommends contacting your local MSC metalworking specialist and the local Lenox application specialist to troubleshoot the problem.

“Lenox carries advanced sawing tools, like tension meters, tachometers, refractometers, feed force gauges and traverse meters, to quickly identify anything on the saw that might be causing the blades to fail,” Guthrie says.

“Our team can make the necessary adjustments, replace worn parts and train operators in best sawing practices to get the blade and sawing performance back to preexisting levels. We can also involve our quality control lab to perform a full metallurgical evaluation of the blade and provide written documentation of the root cause of the failure.”

For over 100 years, Lenox band saw blades, sawing fluids, metalworking lubricants, power tool accessories and hand tools have been the first choice for professionals and leading industrial manufacturers around the globe. Lenox leading manufacturing processes offer innovative, cost-effective solutions in material separation, holemaking and metal forming applications.