Need help? Call us

1-800-645-7270

Shop All Products

- All Product Categories

- Abrasives

- Clamping, Workholding & Positioning

- Fasteners

- Fleet Maintenance

- HVAC

- Hand Tools

- Hardware

- Holemaking

- Hose, Tube, Fittings & Valves

- Indexable Cutting Tools

- Janitorial & Facility Maintenance

- Lighting & Electrical

- Lubricants, Coolants & Fluids

- Machinery

- Marking & Labeling

- Material Handling & Storage

- Measuring & Inspecting

Buying Guides

Explore the fundamentals behind the industrial tools and supplies you use every day. Charts, tips, & product guidance, all in one spot at MSC Industrial Supply.

Explore Buying Guide Library

135 items returned

Measuring & Inspecting

Tape Measures

Safety

Fire Extinguishers

Motion Control & Fluid Power

Coil Springs

Lighting & Electrical

Surge Suppression

Machinery

Lathes

Measuring & Inspecting

Go/No-Go Measuring

Safety

Head Protection

Power Tools

Pneumatic Impact Wrenches

Safety

SPCC Compliance & Secondary Spill Containment

Measuring & Inspecting

Small Calipers

Clamping, Workholding & Positioning

Vises

Indexable Cutting Tools

Boring Bars

Safety

Safety Cabinets

Motion Control & Fluid Power

Bearings

Holemaking

Broaches

Janitorial & Facility Maintenance

Aerosols

Hose, Tube, Fittings & Valves

Flexible Tubing

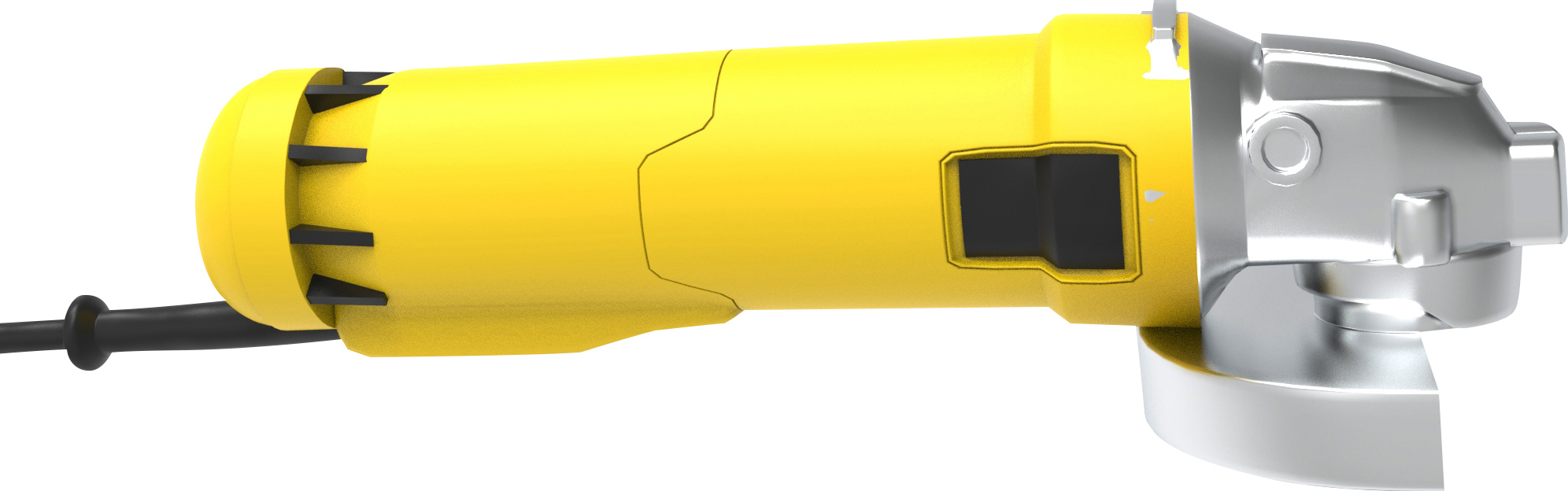

Power Tools

Pneumatic Grinder Safety

Hardware

Padlock Keying

Turning & Boring

Knurls

HVAC

Electric Heat

Raw Materials

Rubber Sheeting

Threading

Taps

Motion Control & Fluid Power